EN 1090 – WPS-Packages

Please choose your desired product.

Content of the WPS package

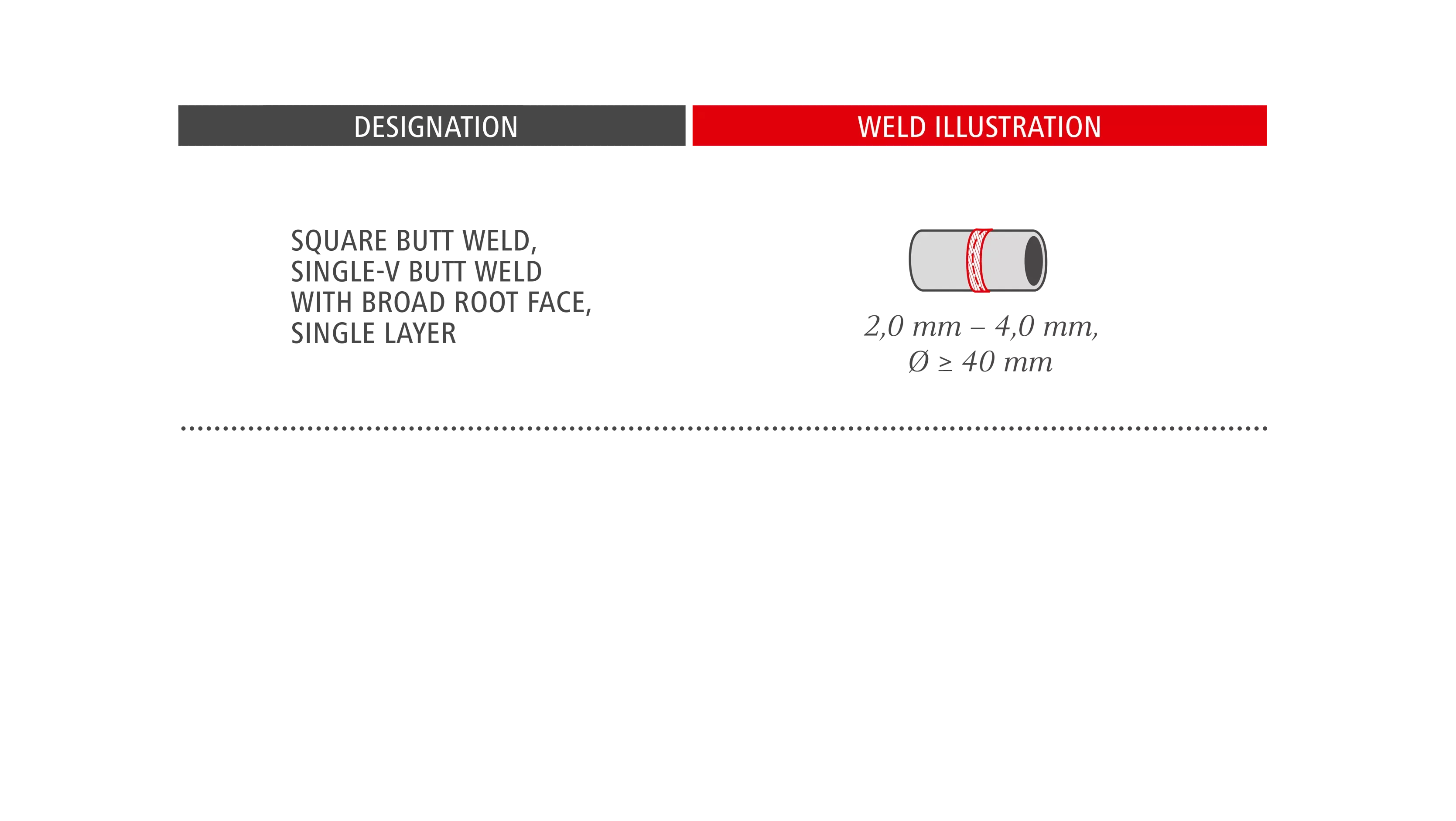

The WPS package steel includes 121 welding procedure specifications for manual applications to material quality up to S460N. Additionally, pipes and tubular constructions are included.

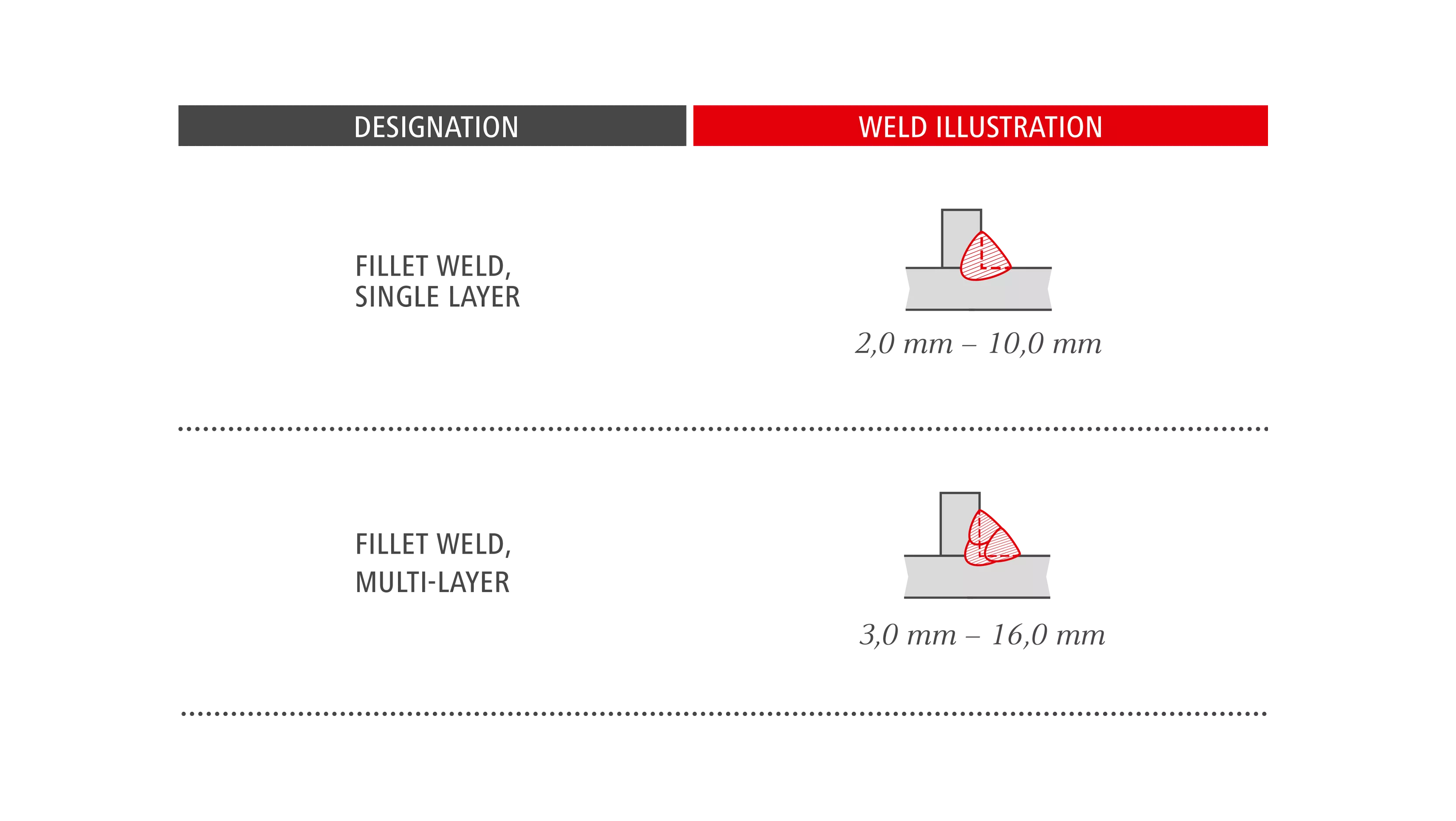

included welding instructions

- MAG process

- Material group: 1.3 (up to grade S460)

- Filler material: G3Si1, G4Si1

- The PA, PB, PC, PF positions

- Sheet thickness range 1.5 mm to 50 mm

- Suitable for welding equipment from allmanufacturers

Supported welding processes:

- MAG dip transfer, intermediate, and spray arc

- MAG pulsed arc

- PMC mixed process

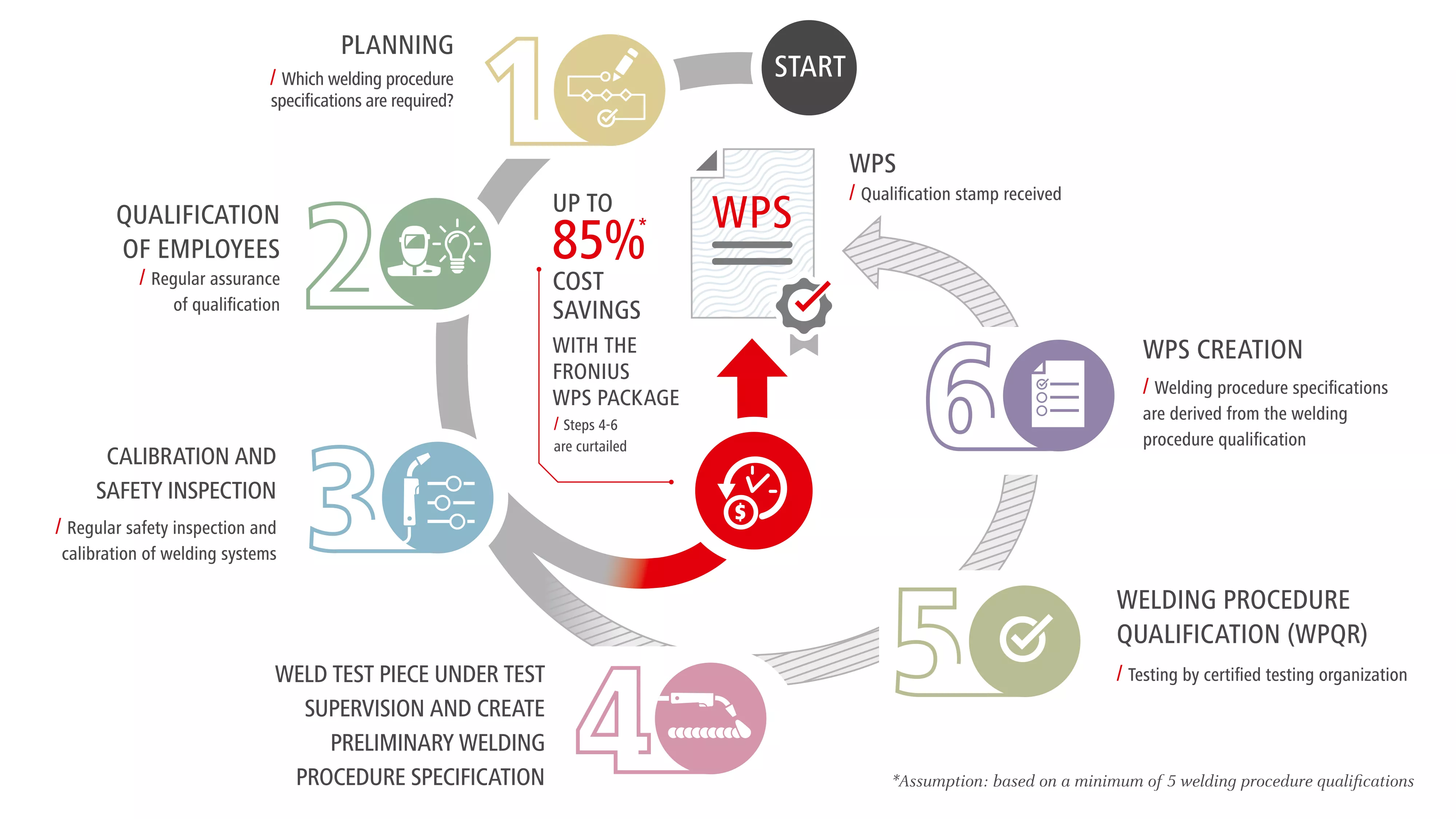

Advantages of the WPS package

With our ready-made welding procedure specifications (WPS), you save on costs for lengthy welding procedure tests and the creation of your own specifications.

*Assumption: based on a minimum of 5 welding procedure tests

Downloads

Creating the finished welding procedure specification

Since EN 1090 came into force in 2014, factory production control (FPC) is required for welded constructions of all execution classes.

This FPC demonstrates that appropriate welding procedure specifications (WPS) are in place at the workplace and work is carried out in line with them.

"While the entire process in steps 1 through 3 requires a great deal of planning work, the cost of qualifying the processes in step 4 is huge, especially for small and medium-sized enterprises. This is where Fronius comes in by offering ready-made and cost-effective WPS packages for manual steel and CrNi applications. The organizational costs associated with welding procedure qualification, which would be necessary to create the welding procedure specifications, are completely eliminated."