Documentation and Analysis

All welding data at a glance

Document welding data reliably

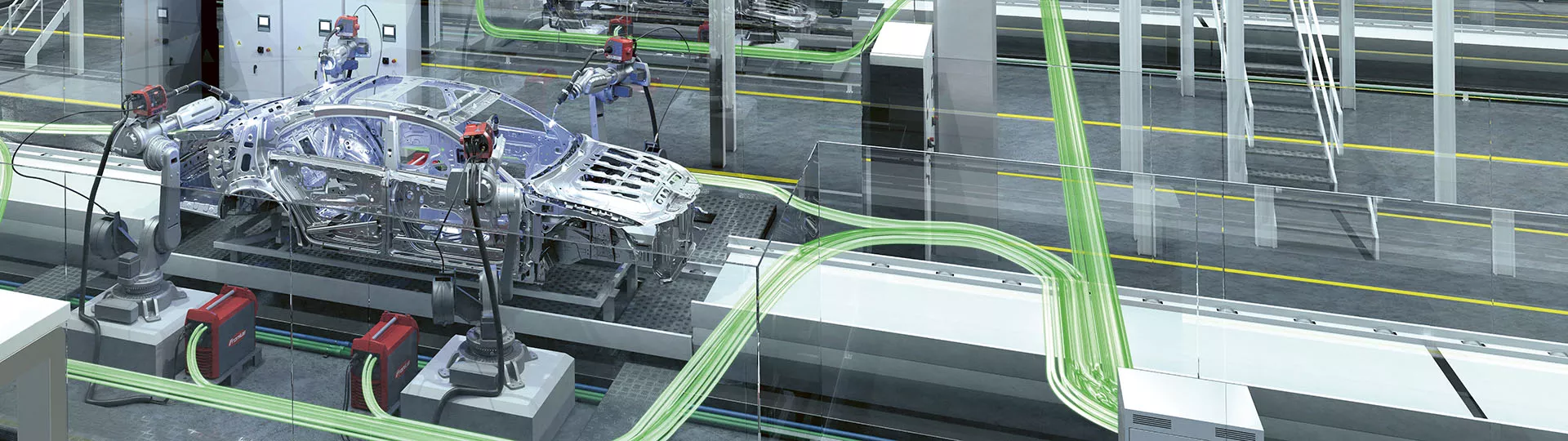

Transparency and safety, but also productivity and time-saving: the requirements are high in welding production. The recording, documentation and analysis of welding data is therefore becoming increasingly important. This is because direct feedback from production helps to optimize processes, monitor system statuses and identify errors. The result: reliable, high-quality production.

The WeldCube analysis system offers the right solution for all requirements—from small businesses to large companies with a wide range of networked welding systems. This means that you get optimum support with your data documentation.

Advantages of data documentation

Read more about the topic of data management here

Quality assurance and transparency

Wherever welding is carried out, manufacturers and users expect perfect and demonstrable quality. Ultimately, stable and flawless weld seams are crucial to ensuring that safety and functionality criteria are met. A continuous quality assurance process is therefore essential in the majority of companies.EU Standard EN 1090 requires welding data documentation

Since 2014, load-bearing steel or aluminum structures may only still be sold if they comply with the EN 1090 series of standards.

The EU standard requires full documentation of the weld seams so that they can be consistently traced.

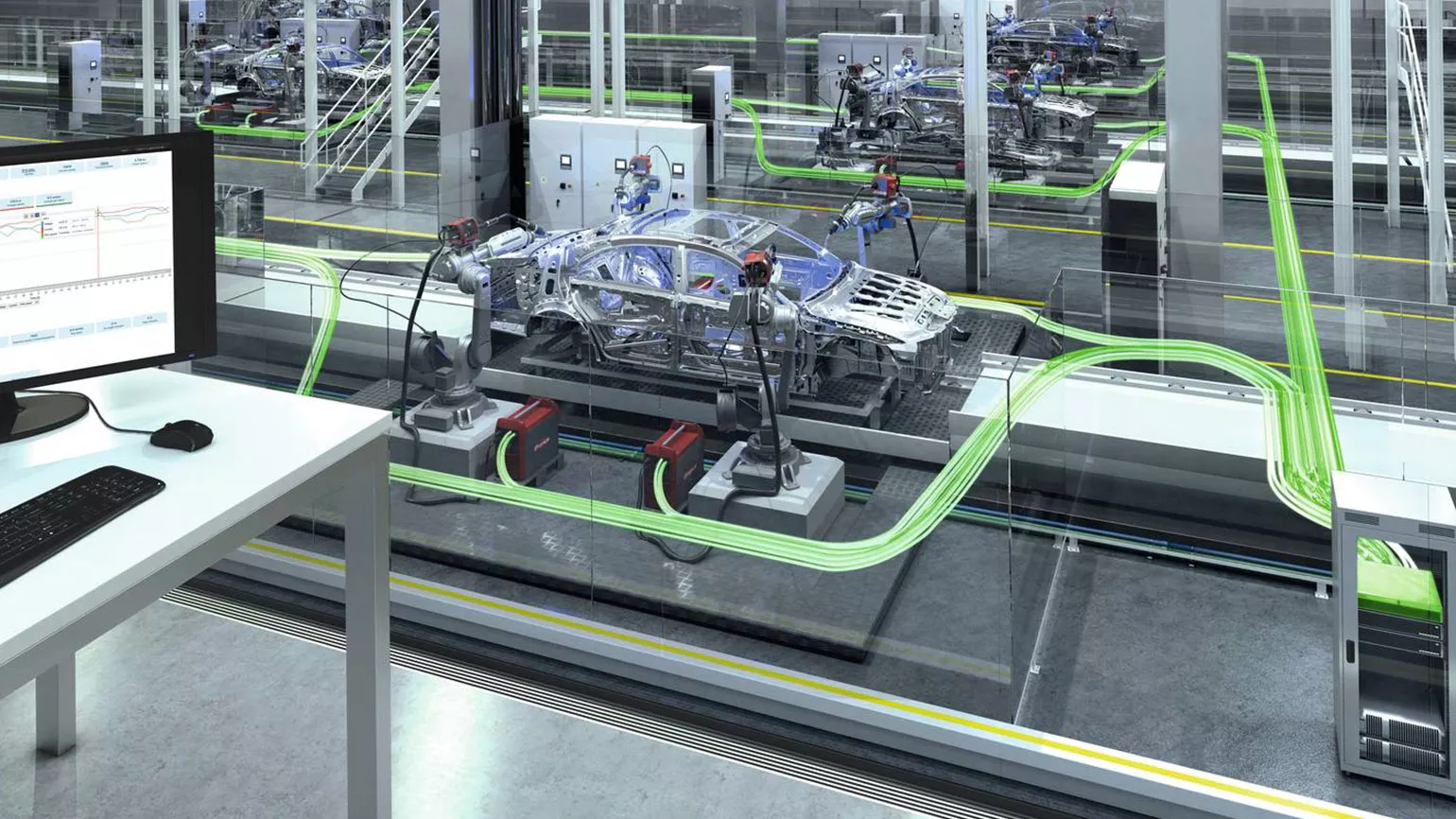

Documentation at component level

The component-level documentation enables weld seams to be assigned to a component and a welding system. This makes it possible to produce components with consistent traceability.

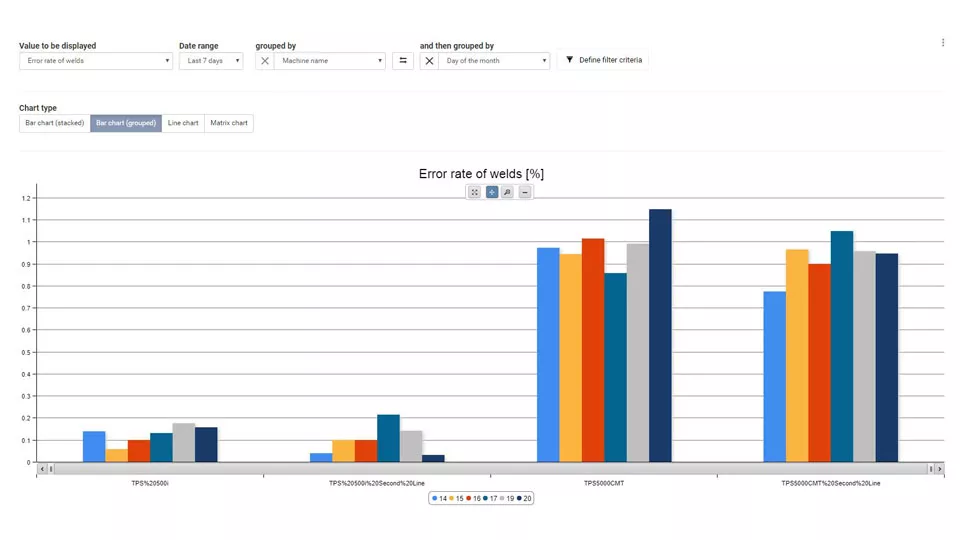

Preparing statistics

Statistics functions allow you to quickly and easily create and visualize useful analyses. This has many advantages for you, including helping you to optimize production processes.

Our example shows the highest error rate per day and welding system, analyzed using WeldCube Premium. Using these data, individual stages of production can be examined in further detail and improved as necessary.

WeldCube: different variants for any requirements

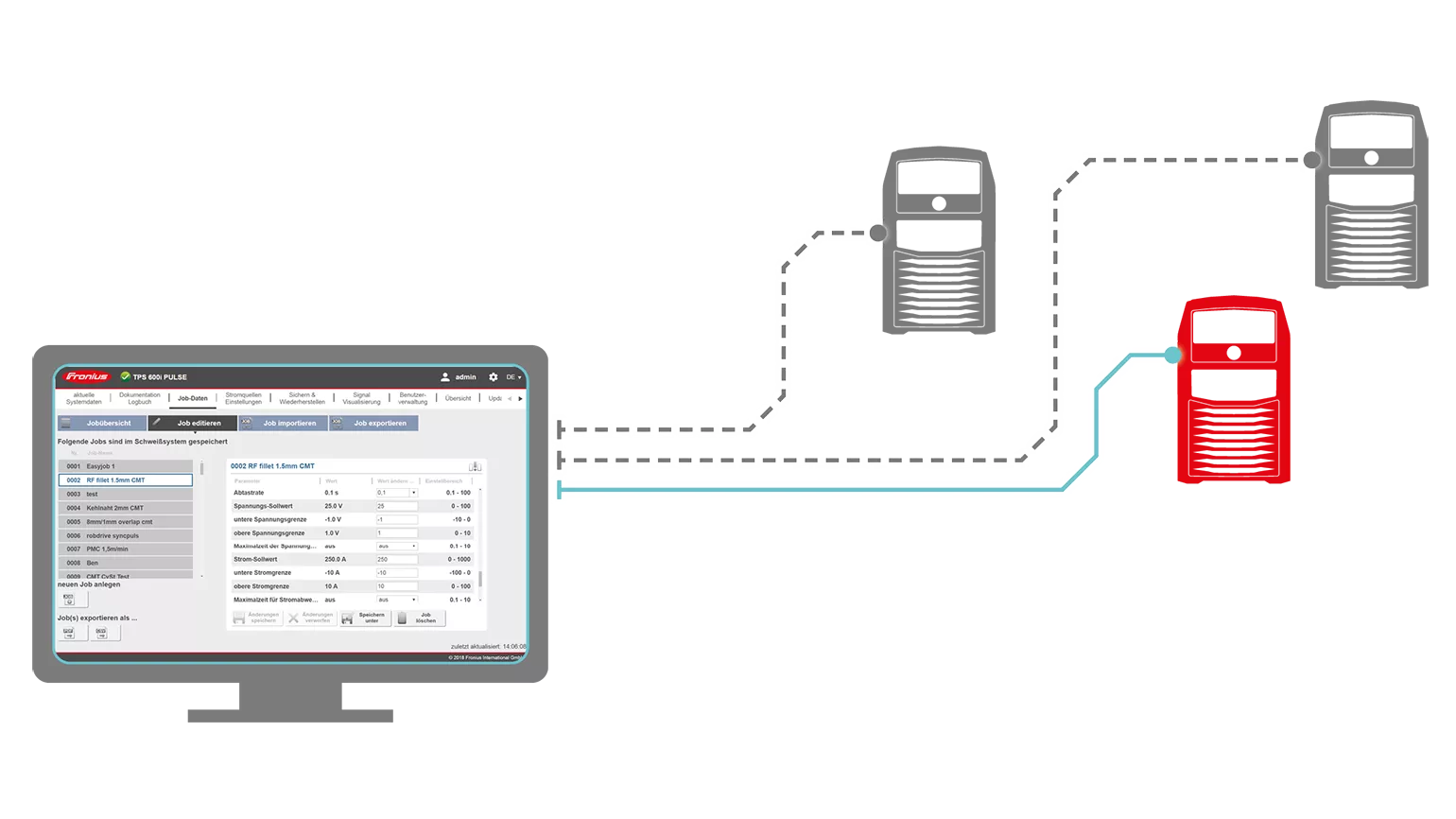

Centralized data documentation

- All data are stored in a central database

- Data from all networked systems are displayed together

Decentralized data documentation

- Data are stored on the power source itself

- Always one power source at a time: view or process data for each individual power source