WeldCube

Welding production at a glance

Any time. Anywhere.

In the smart factory of tomorrow, the aim is to achieve production processes that are faster, more flexible, and more powerful, with the capacity for seamless integration.

Welding data must therefore be subject to complete recording, documentation, and analysis in the field of welding technology, but data also need to be made available for other systems in the production environment.

Fronius offers a number of software solutions in the area of data management, which make it easier for the user to handle the wealth of data.

The software solutions from Fronius...

Save time and money

/ Automated documentation without handwritten notes

/ Analysis at the push of a button

/ Reduced administrative workload

Ensure safety in production

/ Traceability at component and seam level

/ Full documentation of welding data

/ Minimization of risk of error

/ Central administration of user authorizations for Fronius welding systems and software products

Increase productivity

/ Identify potential for optimization

/ Continuous weld-seam monitoring

/ All system status data at a glance

Downloads

WeldCube

Data management

Fronius offers the optimal software solution for the ongoing planning, collection, analysis, and visualization of welding technology production data in the form of the WeldCube product portfolio.

Depending on the WeldCube version, welding and system data can be stored and evaluated either locally in the welding systems or centrally in a database.

Three variants for different customer requirements

Local documentation

with WeldCube Basic and WeldCube Light

- Data storage directly in the welding system

- Data viewed and processed for each welding system

Centralized documentation

with WeldCube Premium

- All data stored in the central database

- Data collection for all interlinked systems

WeldCube Light

Minimal local documentation

standard for TPS/i welding systems* at no additional cost

Mean values for every weld seam are stored directly in the welding system, which can then be separately visualized online for each TPS/i and exported as a PDF file.

The advantages of WeldCube Light

- Supports EN 1090-compliant documentation

- Option to create free documentation

- Immediate documentation without requirement for additional software integration

* except for TPS 270i

Functions

Data documentation

- Mean values of every weld seam are recorded: time, duration, current, voltage, wire speed, power.

- Add columns

- PDF export

- Restrict results using time filters

- Filters for welding operations, faults, and events

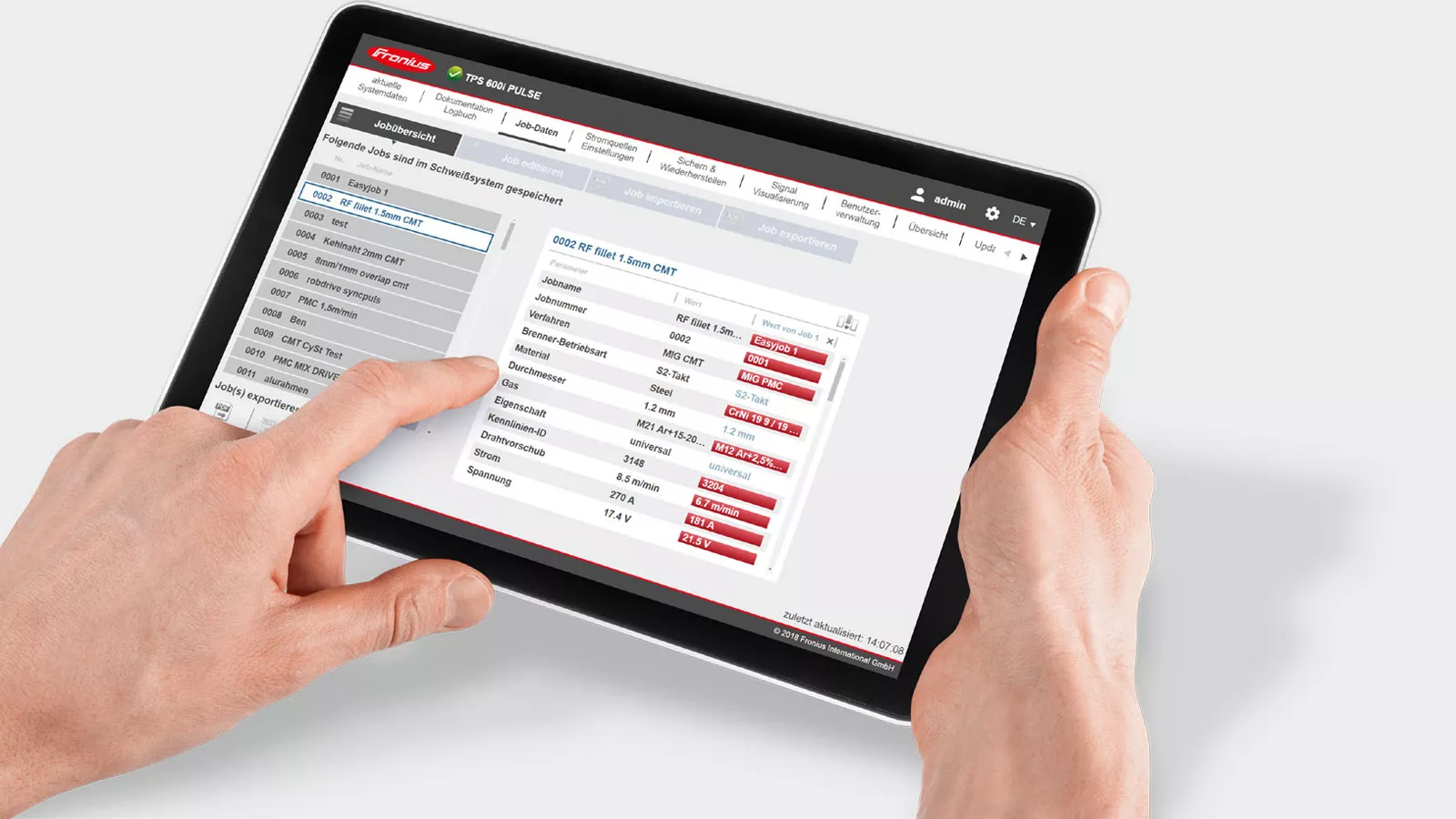

View jobs

- Display of stored jobs

- All parameters of a selected job are shown.

- PDF export

- Comparison of jobs: differences are highlighted in red

WeldCube Basic

Extended local data documentation

with configurable range of functions

For users who need limit monitoring or editing functions for set values and actual values recorded at a sampling rate of up to 100 ms alongside the mean values, WeldCube Basic is the answer. This variant also records data directly in the welding system and visualizes them online for each TPS/i. Furthermore, the data is available as both a PDF and a CSV export.

The advantages of WeldCube Basic

- Variable range of functions: options for job management, actual-value documentation, and limit monitoring

- Ideal solution for smaller companies with few welding systems

- Transparency and traceability at seam level

- Can be upgraded at any time

Functions

Data documentation

- Mean values of every weld seam are recorded: time, duration, current, voltage, wire speed, power.

- Add columns

- PDF/CSV export

- Restrict results using time filters

- Filters for welding operations, faults, and events

- In the event of limit violations, the weld seam concerned is highlighted in red.

Possibility of export via CSV

- Ability to export weld seam data (average value or sampling rate based)

- Additional parameters can be exported if needed

- Save CSV files

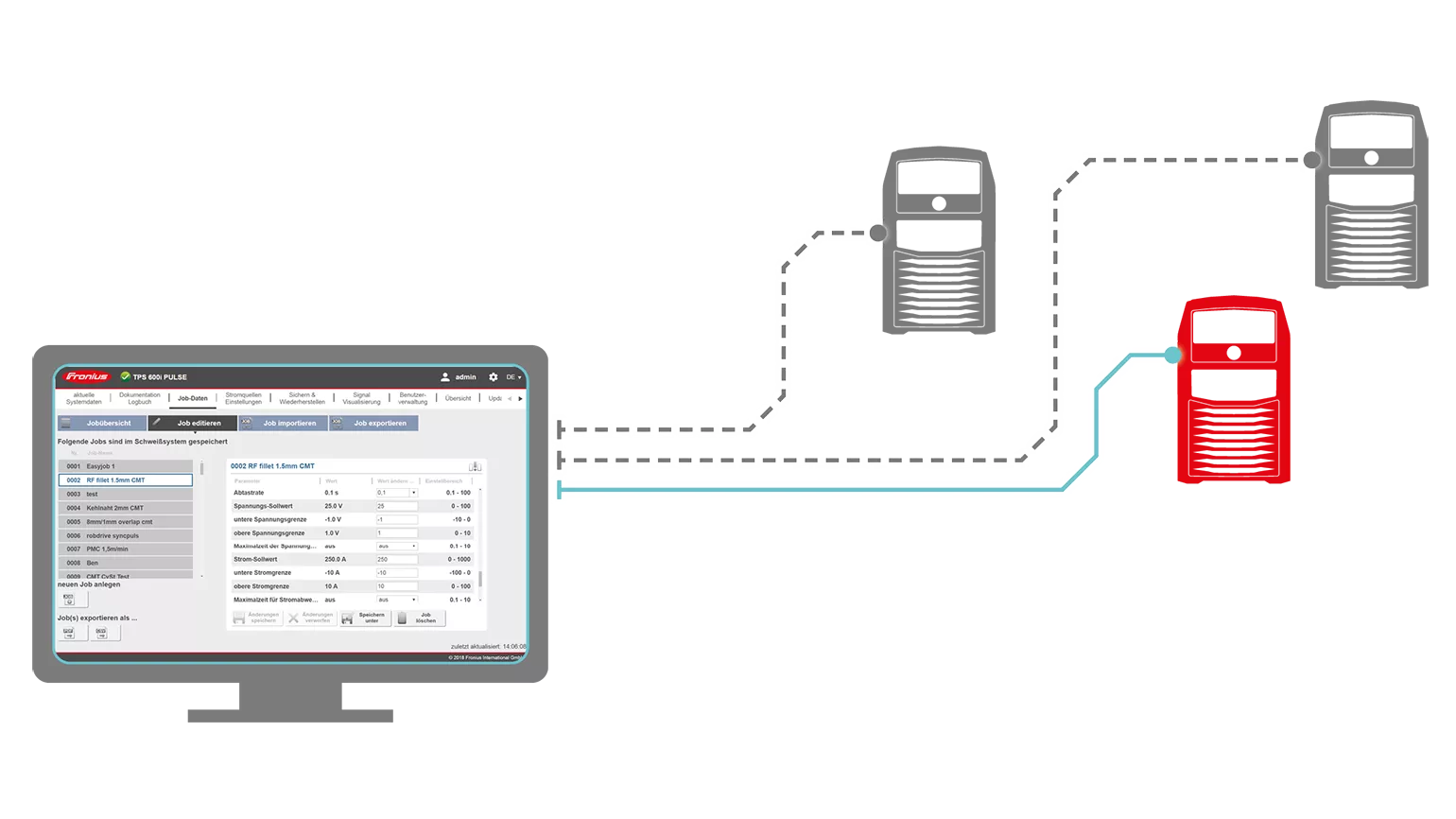

Edit jobs

- Edit jobs

- Values can be directly changed

- Display of possible adjustment range

- Jobs can be exported and imported on other devices

- Upper and lower limit values can be set for the basic parameters (A, V, Vd)

Functions

Workpiece monitoring in real-time

- Traffic light system for every weld seam

with position

Yellow = Not yet welded

Red = Faulty due to limit violation

Green = Correct - Details on every weld seam directly accessible

- Status bar displaying component progress

- Information on component

Details to every weld seam

- Actual data at selected time

- Overview of actual data across the entire weld seam

- All information on selected weld seam

- PDF export with all data on selected weld seam

Job-history

- Every change in the job is traceable down to the finest detail

- The selected job can be restored at the click of a button

- Changes in the job are highlighted

All information of the welding machines

- Information on selected welding system with direct link to device

- Overview of available and installed function packages

- History of installed hardware

- All jobs on the selected welding system can be edited and distributed to other devices

- Error messages are saved in the log book

- Access to all weld seams produced by this device

Customizable dashboard

- Customizable dashboard

- Widgets can be placed on the screen

- Status of welding system

- Statistics on the total number of welding operations performed

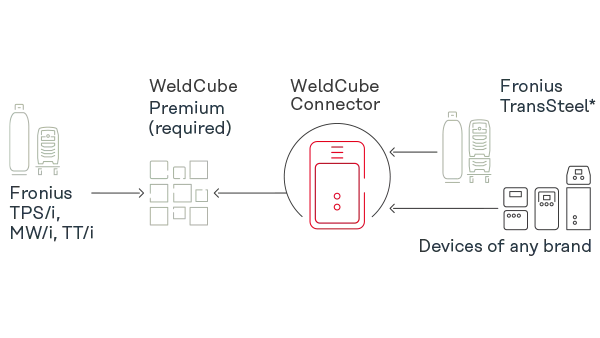

WeldCube Connector

Full documentation of all your Power Sourcesin one place – the complete Welding DataDocumentation.

New:

/ integrate TransSteel into WeldCube Premium

/ integrate devices of any brand into WeldCube Premium