PMC

Pulse Multi Control

PMC welding process - faster, more economical welding

With its optimized pulse characteristics, Pulse Multi Control provides high-quality welds at high welding speeds. With penetration stabilizer and arc length stabilizer, gaining control over the arc has never been easier.

PMC represents a further development to the pulsed arc, including its stabilizers. The modified process is characterized by precisely regulated and low-spatter droplet detachment. At the same time, PMC generates a powerful and stable arc, which facilitates perfect control of the weld pool. Irregularities during welding—such as undercuts—are thereby avoided, while the welding results are always reproducible and stable.

The benefits for you

Optimized pulsed arc

/ Enhanced process stability from precision adjustment control

/ Spatter-free ignition (SFI)

/ Improved pulse shape

Improved weld properties

/ 15% higher welding speed*

/ 15% less energy input*

/ Consistent penetration

High weld seam quality and appearance

/ Optimized welding of vertical-upseams thanks to the “PMC Mix” characteristic

/ 100% control with arc length and penetration stabilizer

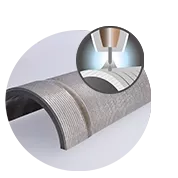

/ TIG-like seam rippling thanks to PMC Ripple Drive

Downloads

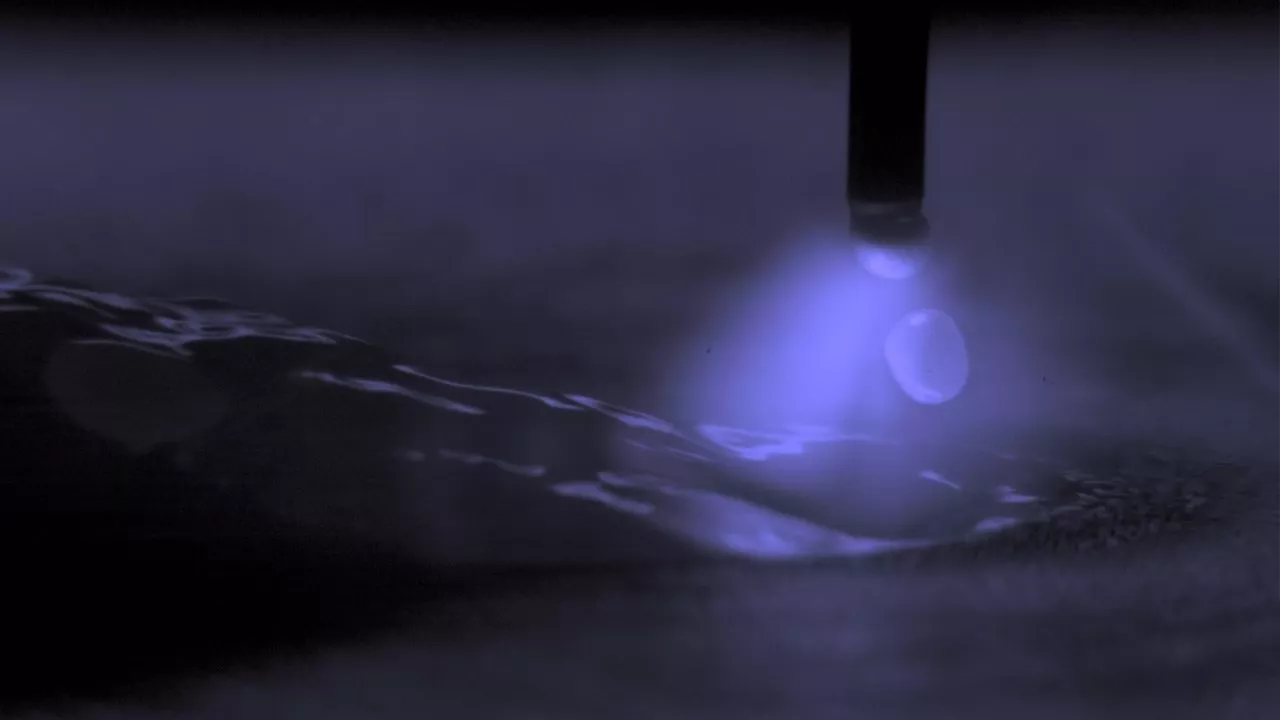

Stable ignition and minimal spattering

Spatter-free ignition (SFI)

SFI ignition causes a retraction movement of the wire electrode at a low current level; this results in a guaranteed stable and reproducible start to welding.

Furthermore, SFI HotStart with increased arc energy in the ignition process reduces the risk of fusion defects—in particular with aluminum.

Manual welding with PMC

Weld vertical-up seams at top speed without oscillating motion

The PMC Welding Package includes several characteristics, meaning you enjoy a range of benefits. We offer the optimal support you need for perfect seams in every application. For example, PMC Mix is for vertical-up seams and allows up to 40% higher speeds because oscillating motion is eliminated.

Package contains:

- Universal

- Arc Blow

- Dynamic

- Mix

- PCS

Robotic welding with PMC

There are a range of requirements for robotic welding

No matter whether the objective is higher welding speeds, the perfect seam appearance, or reproducible quality—Pulse Multi Controlfully satisfies all these requirements. The result is a package of different characteristics that is perfectly tailored to the customer’s requirements.

90% fewer ignition failures thanks to SlagHammer*

Cleaner and safer start to the welding process: Silicate islands that have been deposited on the seam surface from previous welds are knocked off by the reversing wire movement during the ignition process.

Package contains:

- Braze

- Multi Arc

- Cladding

- Galvanized

- Mix Drive

- Ripple Drive

*according to customer calculations

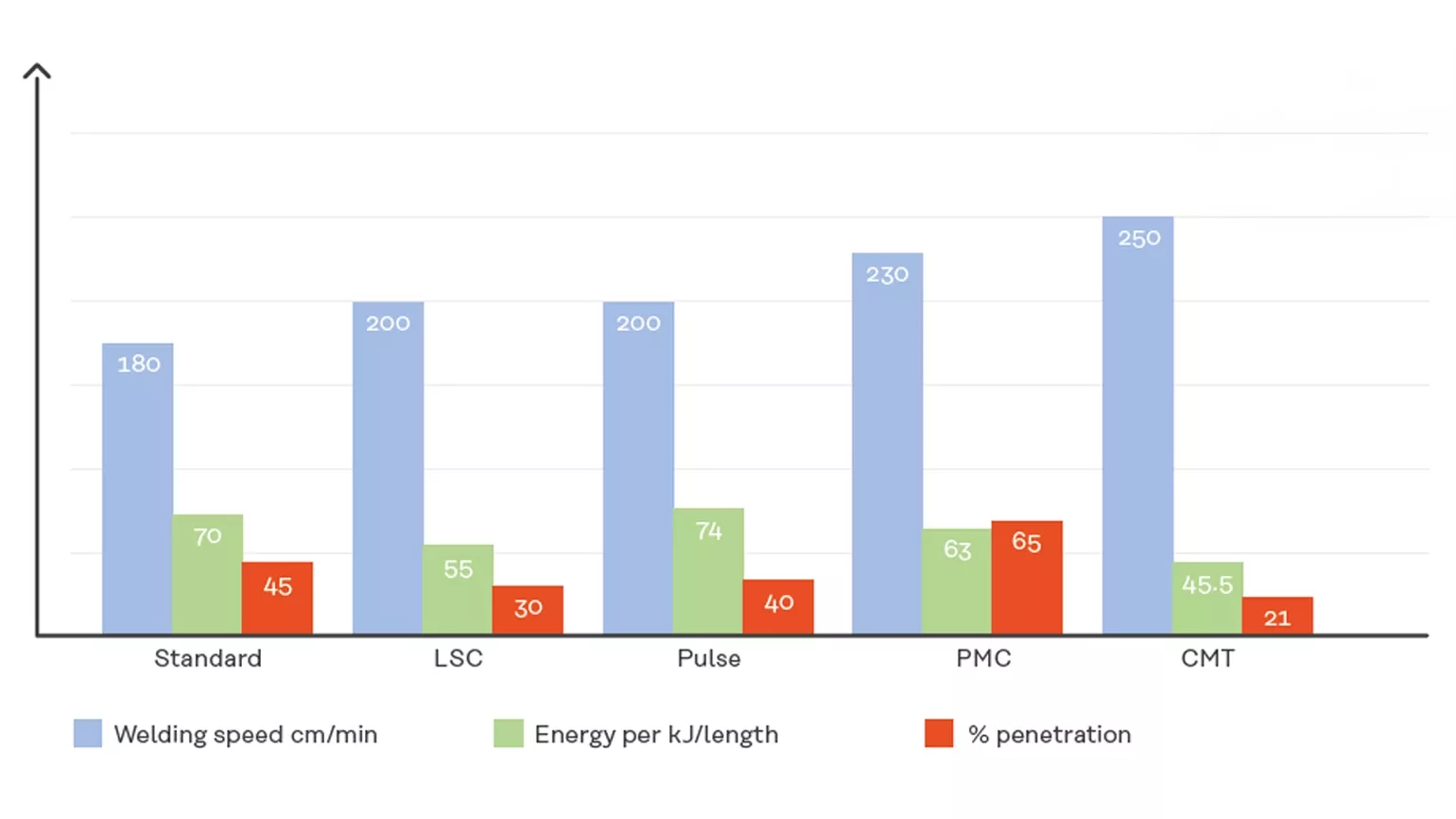

Comparison of Welding Packages

– TPS 500i

– WF 25i

– For CMT comparison: additional reel, SB60, Robacta Drive

– 7° torch contact angle, with slight push and at 15° relative to the workpiece and welding table in 30° PG position

– Filler metal: G3Si1 (1.2 mm diameter)

– Shielding gas: M21 (18% Ar + 82% CO2, 12 l/min)

– Parent material: 2 mm ground steel plate

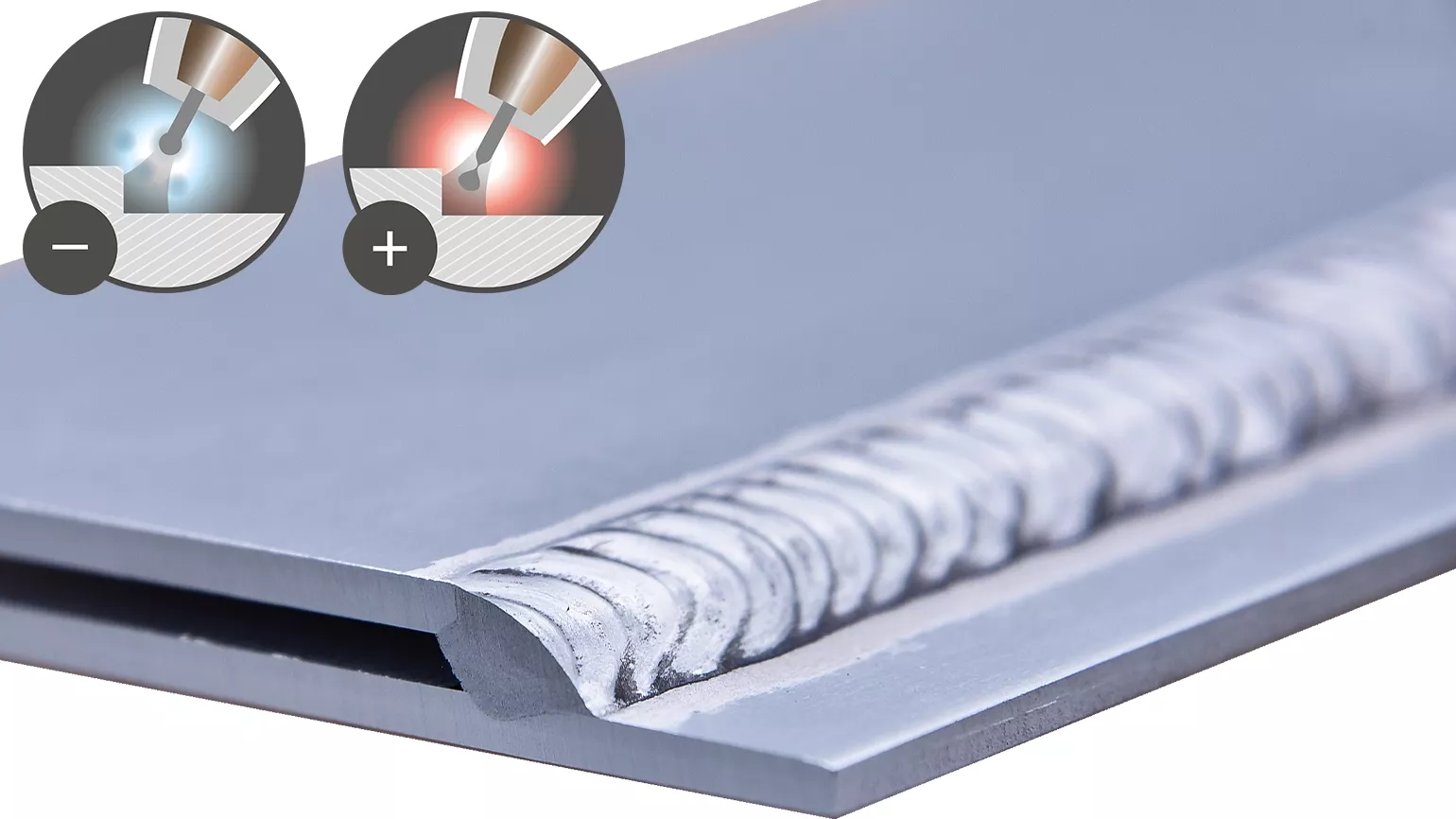

PMC AC*

Reverse polarity of the wire electrode

Optimal for welding thin or ultra-light gage sheet joints: the PMC AC process enables remarkably low heat input at a constant deposition rate. The special thing about this technology is that the positive and negative component can be easily adjusted with the help of correction parameters. The result is precise control over the heat input.

The benefits:

/ Low heat input

/ Excellent gap-bridging ability

/ Easy arc handling for manual and automated welding

/ Gleaming welds due to reduced magnesium oxides (for AlMg wires)

/ Lower welding fume emissions

* PMC AC is available on the iWave AC/DC with Multiprocess Pro.

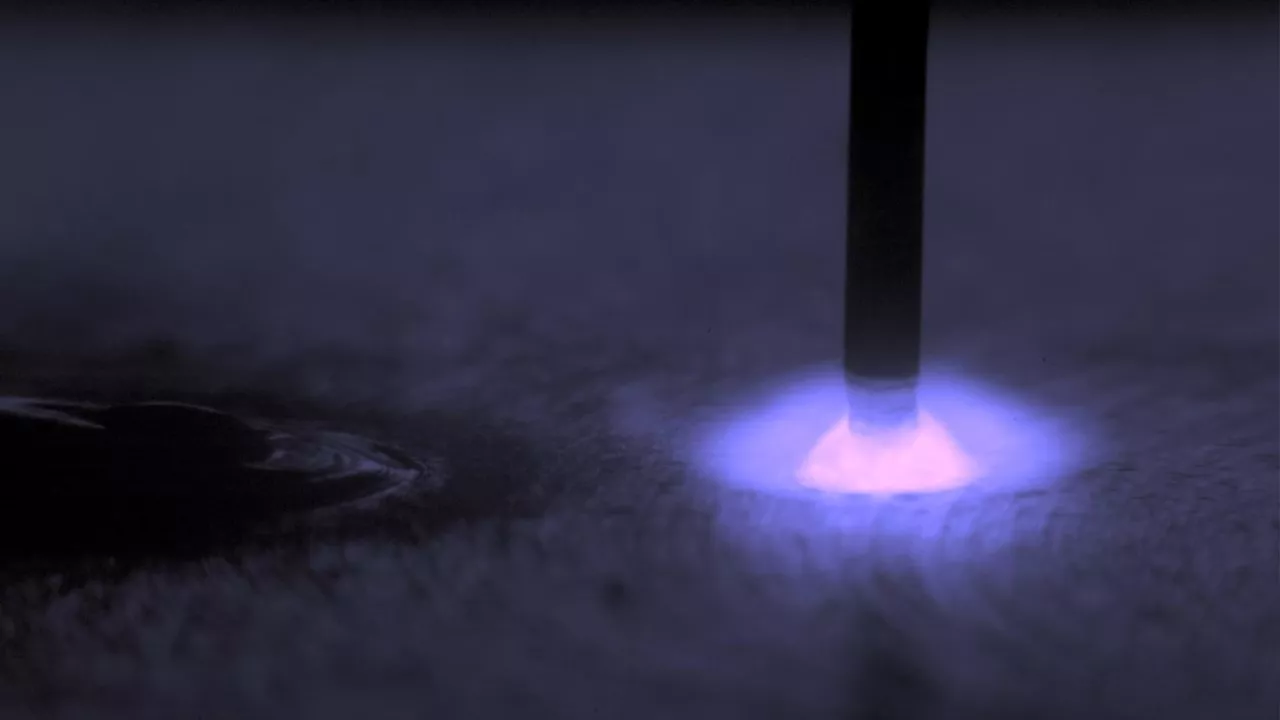

Penetration and arc length stabilizer

It’s all about the wire speed

Supported in different applications: it compensates for stickout changes, paving the way for an almost constant level of weld seam quality.

With an activated penetration stabilizer, the system readjusts the wire speed rather than the welding current. This results in constant penetration. An additional wire control keeps the current and penetration constant if the distance between the welding torch and the component changes. As a result, the arc becomes much more stable, while penetration always remains the same.

The benefits:

/ Improved welding quality

/ Savings in rework and costs

/ Ideal support in case of insufficient visibility or accessibility = stickout fluctuations are automatically compensated for

/ Ideal for position welding

/ Narrower opening angles can be used, saving on filler material

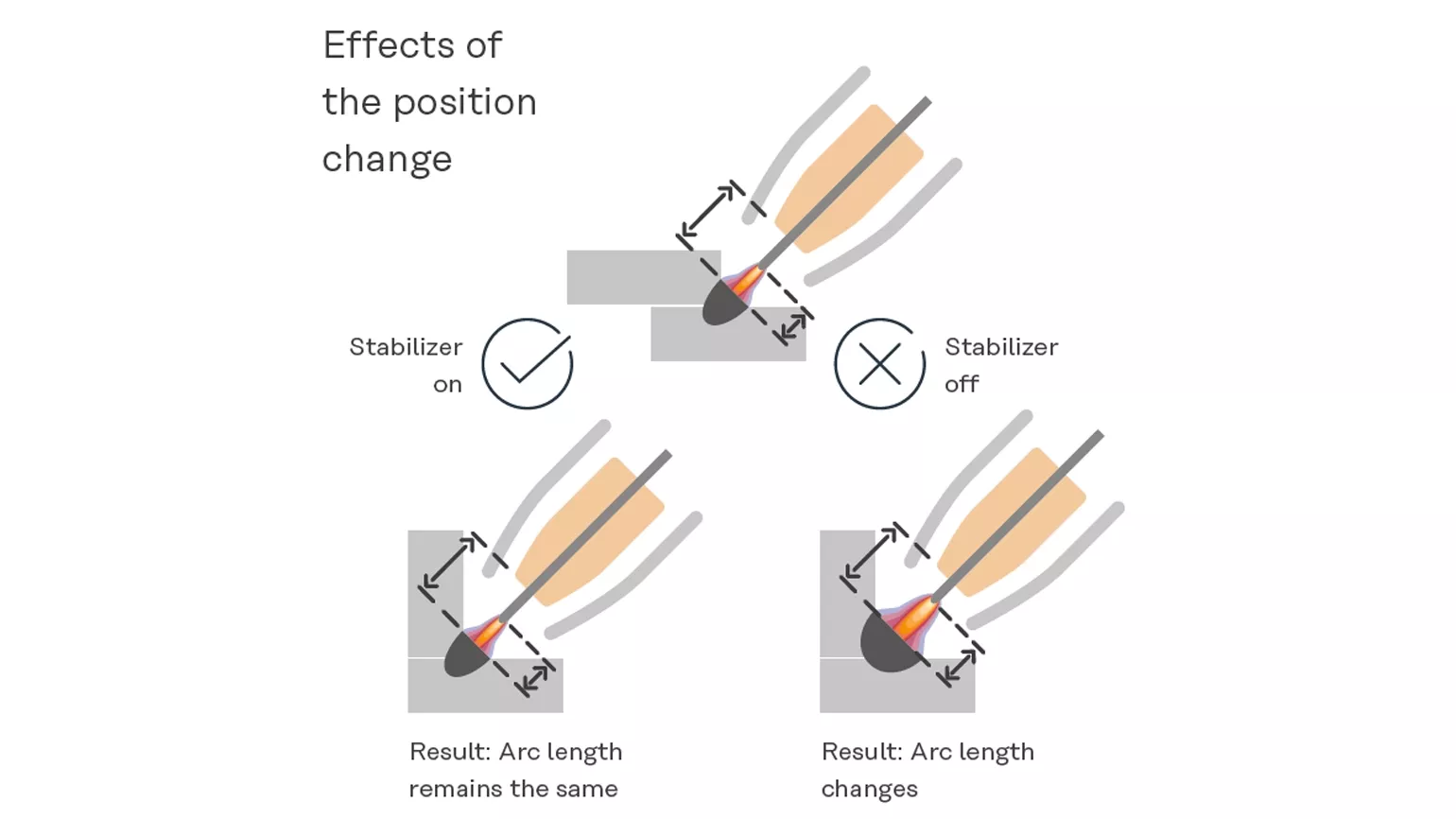

Arc length stabilizer

for a constant arc length

Automatically compensate for irregularities— the arc length is kept constant regardless of the welding voltage. This results in the seam quality remaining unchanged even if the torch position changes or the component tolerances vary.

Optimum support for the following circumstances:

/ Dynamic, changing position of the torch

/ Component tolerances: changing sheet thicknesses or gaps

/ Irregular heat dissipation

/ Changes in speed

The benefits:

/ No need for the welding operation to be interrupted or for manual readjustment of the arc length when the torch position changes

/ Reduced risk of undercuts

/ Quick determination of parameters

/ Focused arc

/ Higher welding speeds