iWave

for automated welding solutions

iWave—The all-rounder in automated welding

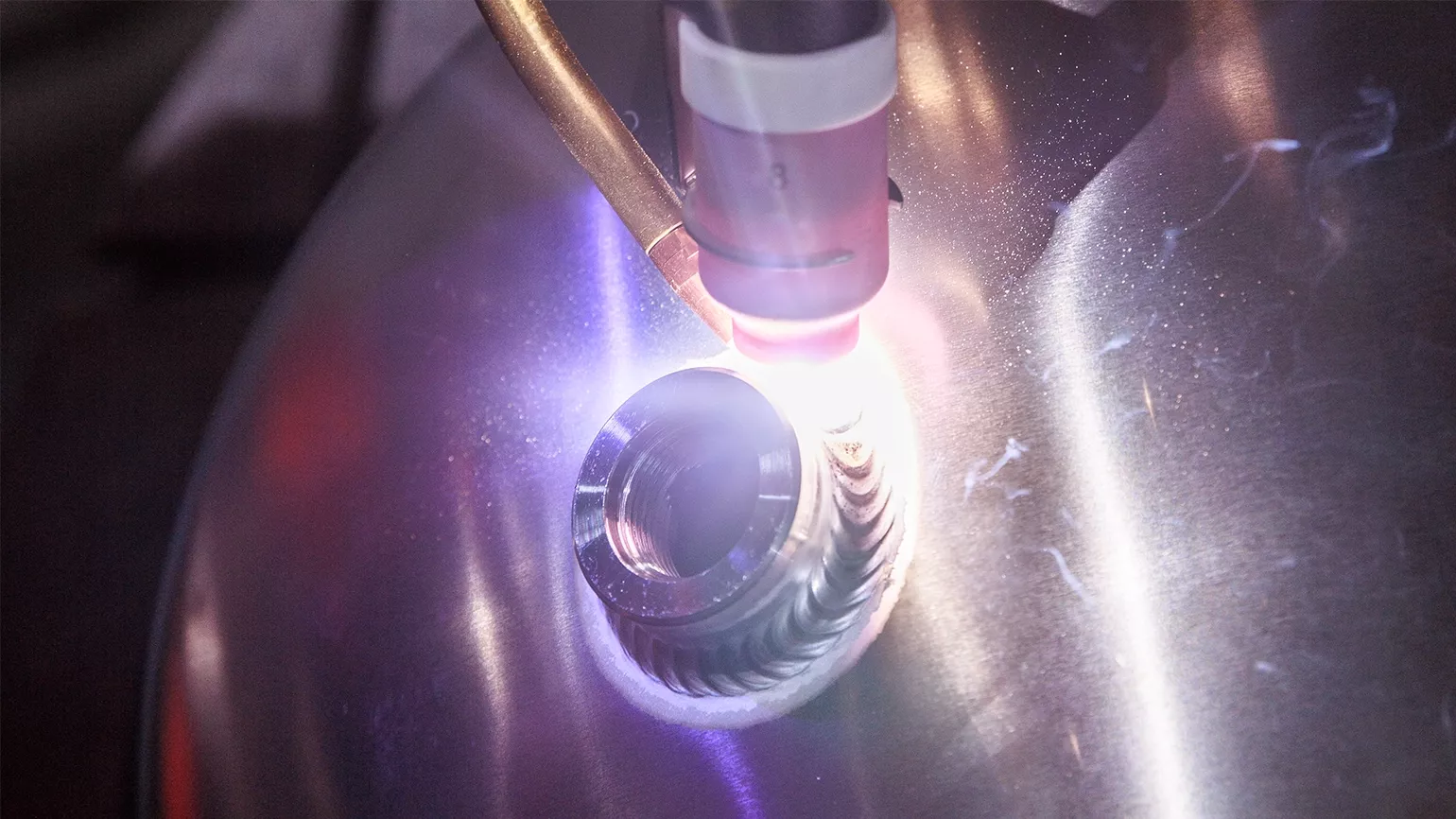

Top quality for every weld and every material: thanks to new technologies, iWave offers advantages for more targeted heat input, significantly improved ignition, and therefore maximum control over the arc.

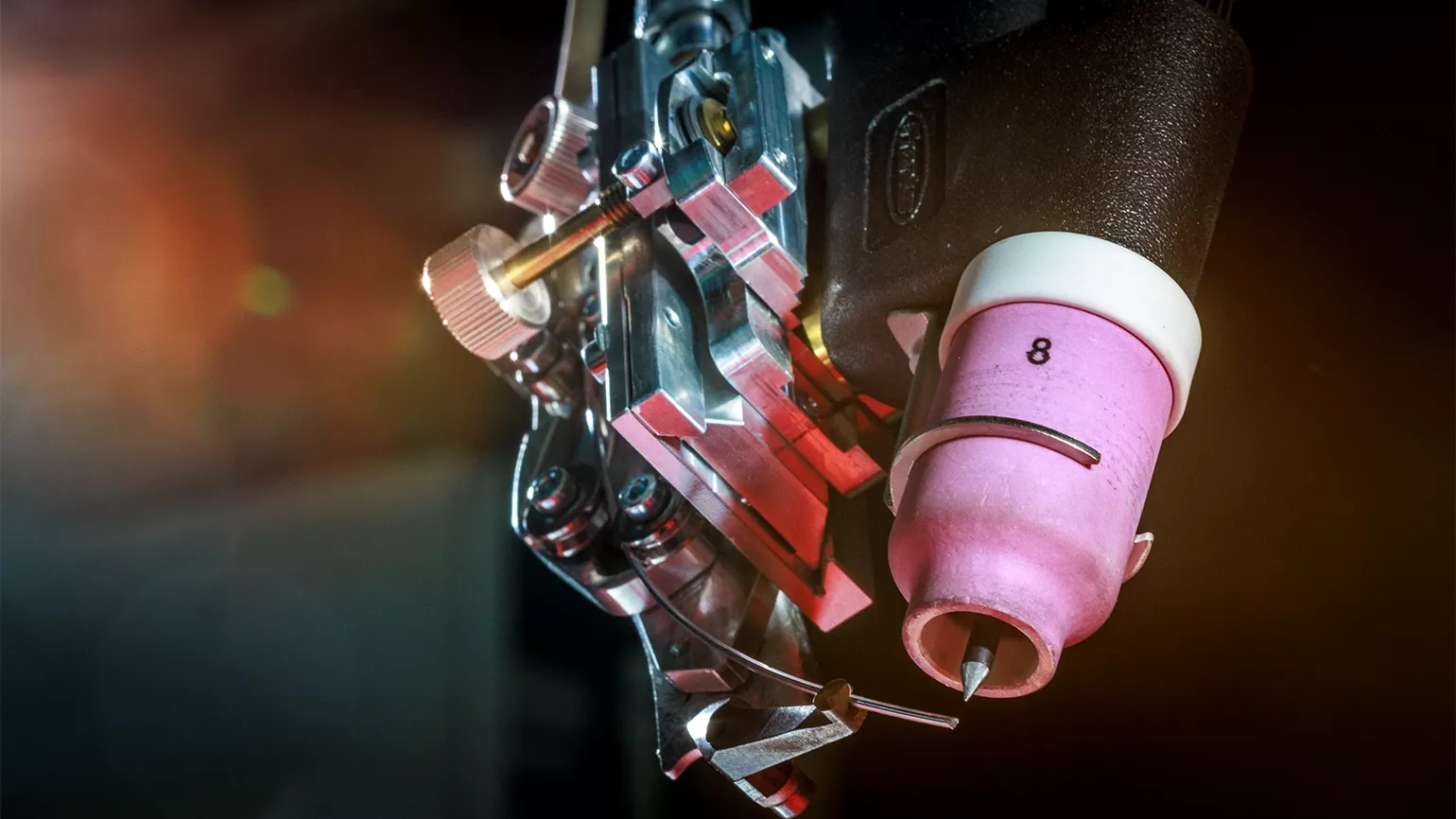

Cold wire TIG welding made easy: with DynamicWire, key challenges of TIG cold-wire welding, such as gap bridging and quickly identifying the right parameters, are incredibly simple. Process control is elevated to a new level.

Need a system that can master the full array of welding challenges? If so, iWave Multiprocess PRO is the perfect choice: in addition to offering every imaginable TIG function, it also accommodates all MIG/MAG welding process variants.

The advantages for you

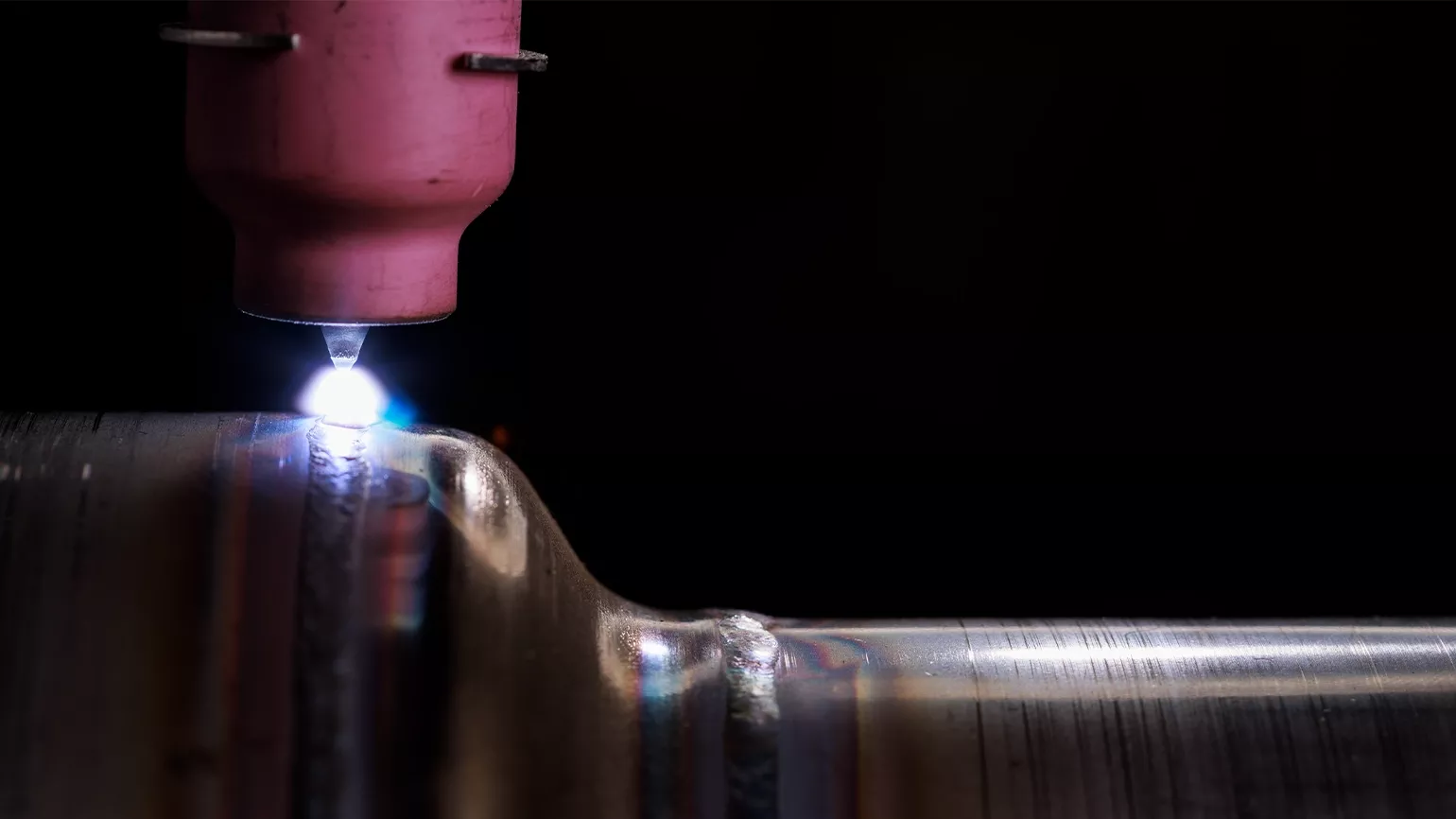

Dynamic wire feeding

Gap bridging up to 30% possible

The DynamicWire feeding system automatically adjusts the wire feed speed to the current conditions during welding. The wire is always supplied in the exact quantity required, allowing air gaps of up to 30%* to be compensated for and welded.

* in relation to the material thickness

Targeted heat input

Maximum control of the weld pool

CycleTIG allows you to control the arc, in turn giving you maximum control over heat input. Short welding times allow you to keep the weld pool safely and easily under control, making it simple to weld even the thinnest materials.

Reproducible ignition

Up to 71% less ignition delay

Our RPI auto intelligent ignition function offers fast and, above all, reproducible ignition—without any manual adjustment of the ignition parameters and with any material properties.

Multiprocess PRO

One system for every process

Complete freedom during automated welding: with iWave Multiprocess PRO, you can use all MIG/MAG process variants in addition to all TIG functions with a single machine. The modular concept allows you to individually expand your high-tech welding machine platform with the Standard, Pulse, PMC, LSC or CMT welding packages.

Spring-loaded CrashBox

Z-triggering in minus direction

Improved seals on the new CrashBox prevent the ingress of dirt, meaning that this has no influence on the accuracy of the TCP (Tool Center Point). In the event of collisions, the option of Z-triggering in the minus direction is also advantageous.

Interfacing

One interface for every process and a uniform process image

Thanks to the standard high frequency resistance, all existing interfaces of the TPS/i welding systems can now also be used for iWave or TIG welding without additional hardware. There is now one interface for every process, including a uniform process image.

System overview

DynamicWire

Active wire control—automated TIG cold-wire welding made easy

Despite its advantages, automated TIG cold-wire welding presents various difficulties. Finding the right welding parameters is a key challenge. With DynamicWire, you only have to set one parameter: the rest are stored using material-specific characteristics.

The innovative advantage of Fronius TIG DynamicWire compared to conventional continuous wirefeeding in cold wire systems lies in its automatic self-regulation. The welding machine actively adjusts the wire speed to the current conditions. Air gaps of up to 30%* can be welded with DynamicWire—previously almost impossible with cold wire TIG welding.

The TIG DynamicWire Welding Package can be quickly added to automated iWave systems with a cold-wire feed from 300i-500i. Simply activate the software and get welding!

The result? Perfect welds every time. Existing iWave cold-wire systems can be easily upgraded with the patented TIG DynamicWire Welding Package through software activation.

The advantages for you:

- Always the right wire speed

- Air gap bridging of up to 30%* possible

- Set just one parameter to start welding

* in relation to the material thickness

Targeted heat input

Very targeted heat input can be generated by means of a short interval time, a low or no base current, and a long interval pause time. Areas of application include edge application or repair work on die-cast parts.

Outstanding weld appearance

Combined with the tacking function, CycleTIG enables the welder to achieve an excellent seam appearance.

Fewer temper colors

The use of CycleTIG reduces temper colors and therefore keeps the need for rework to a minimum.

Easy control of the weld pool

Thanks to the short welding time, the weld pool can be well-controlled with ease. This prevents burn-through, particularly in corner and butt welds.Multiprocess PRO—Equipped for the challenges of tomorrow

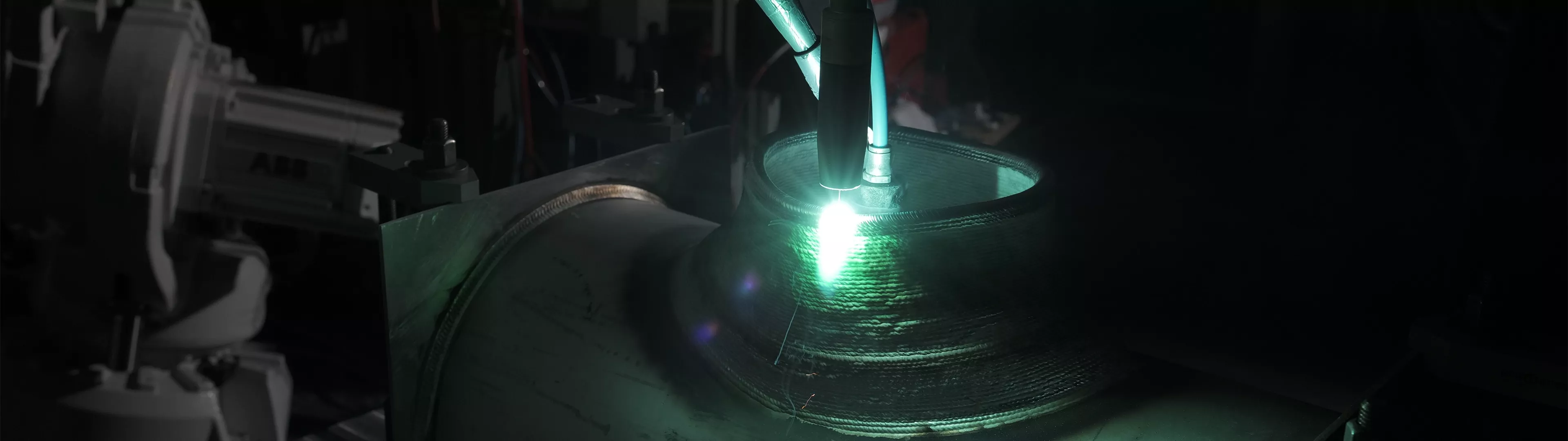

Complete flexibility—One welding machine for all processes and process variants

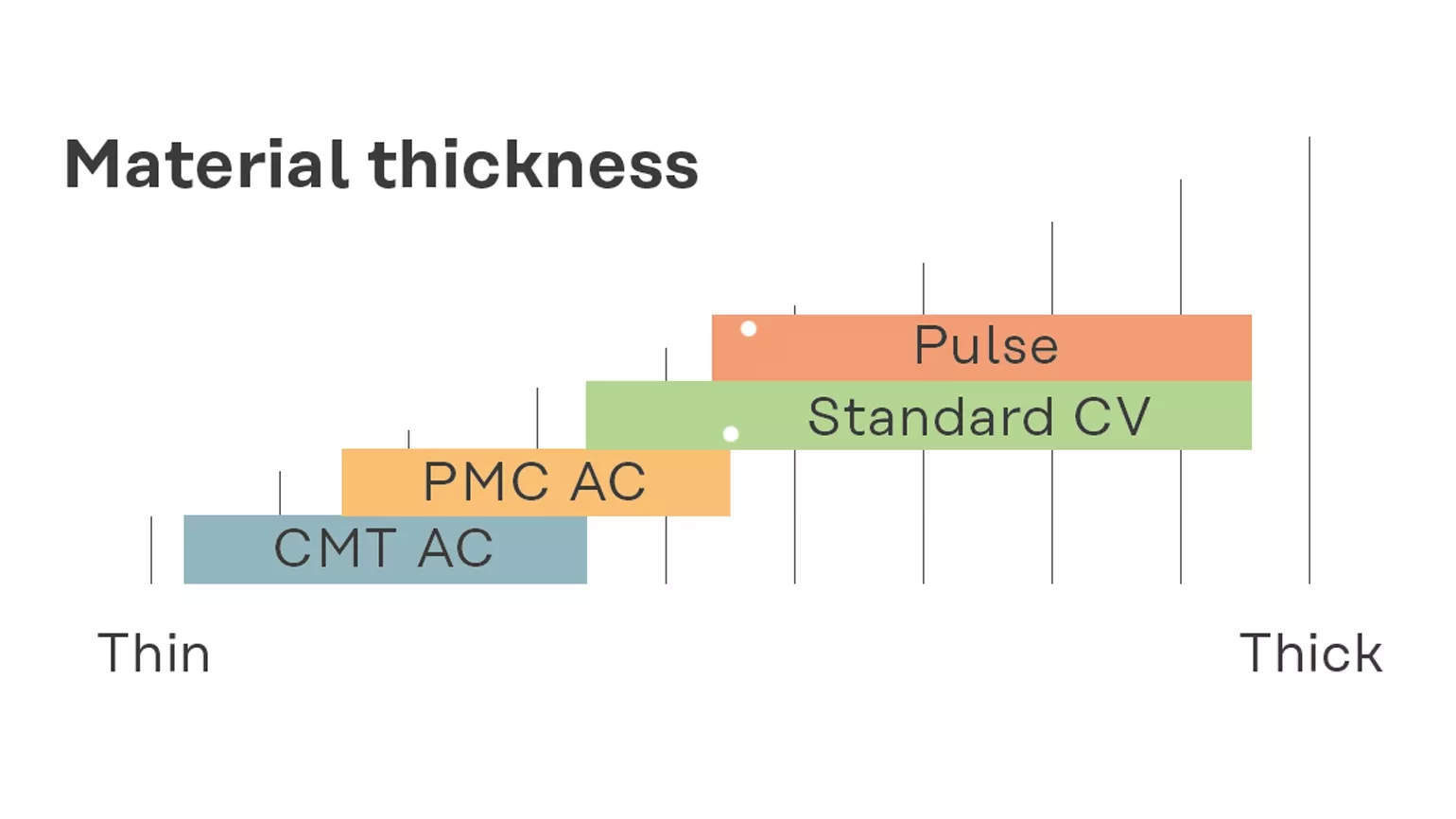

No matter whether it’s with TIG or MIG/MAG welding, the iWave 300i, 400i, or 500i and the Multiprocess PRO hardware option give you complete freedom in your welding production. The main difference compared to conventional multiprocess systems: in addition to all high-tech TIG functions, you also have access to every process variant from the field of MIG/MAG welding.

Equipped with the right peripheral components such as welding torches and wirefeeders, you can put together the precise functions you need from the modular welding packages Standard, Pulse, PMC, LSC, CMT, PMC AC, and CMT AC. Additive manufacturing is also possible with the iWave.

The advantages for you

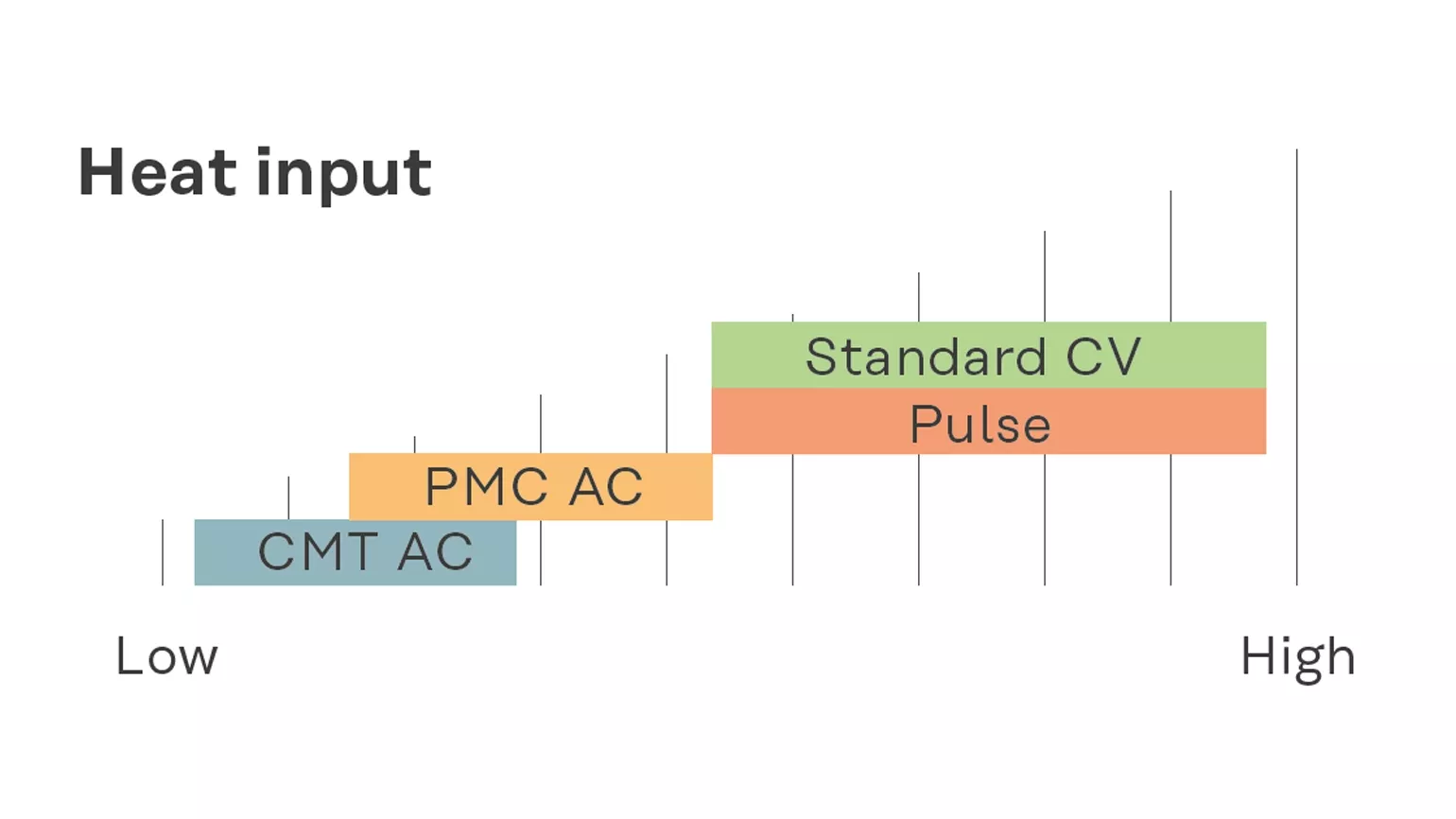

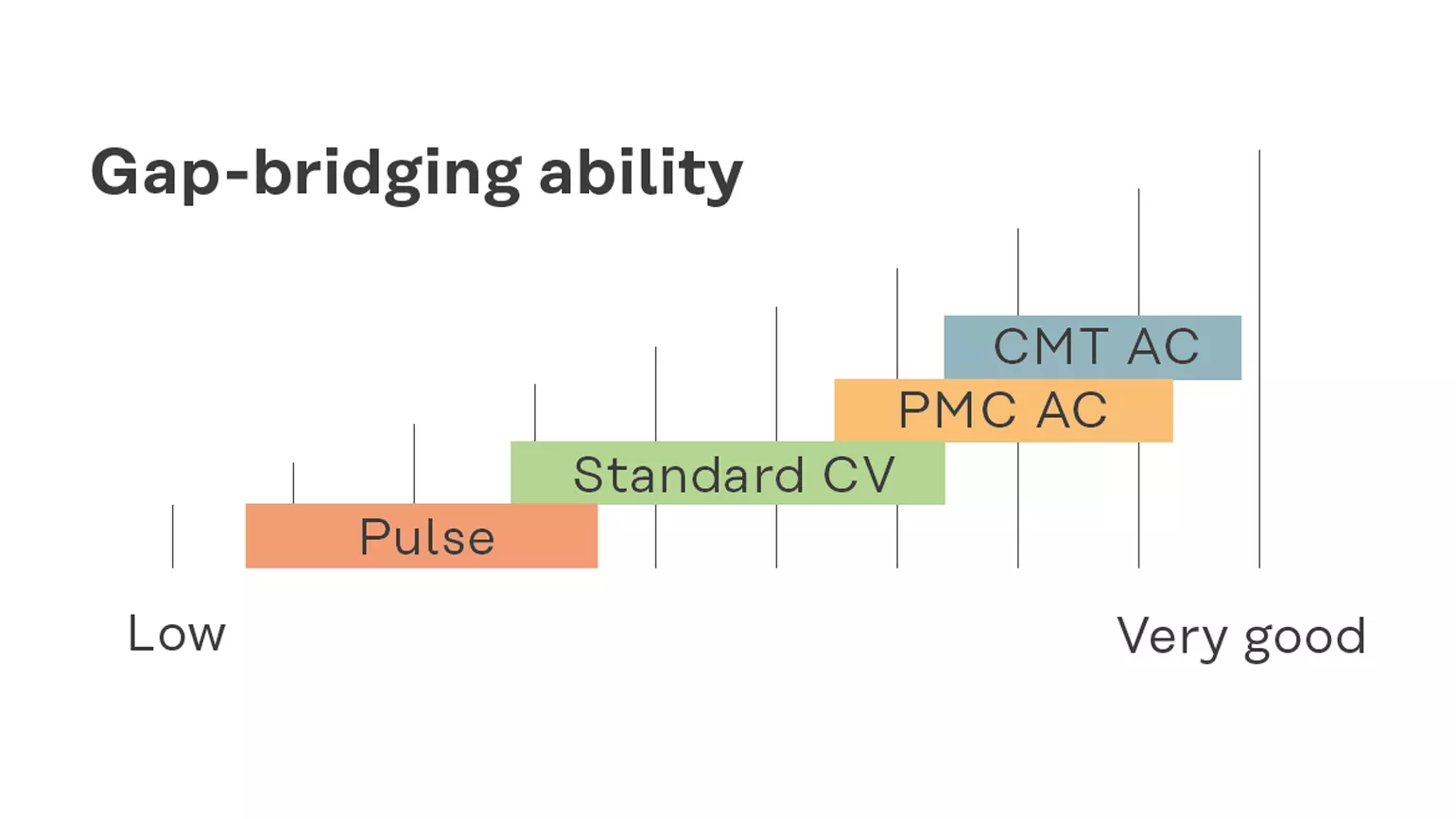

CMT AC

Our solution for even lower heat input during MIG/MAG welding

The CMT AC process achieves a remarkably low heat input with the same deposition rate by reversing the wire movement and the polarity of the wire electrode. With this technology, you can easily adjust the positive and negative components with the help of correction parameters and thus achieve extremely precise control over the heat input.

The benefits

/ CMT AC is the process with the lowest heat input

/ Excellent gap-bridging ability

/ Ideal for additive welding

/ Highly controllable heat input, especially for additive manufacturing processes

/ Gleaming welds due to reduced magnesium oxides (for AlMg wires)

/ Process with the lowest welding fume emissions

Performance for the industrial future

The SmartManager is a web-based solution in the field of welding technology. As part of the welding system, the SmartManager provides advanced setting options.

Data acquisition and control minimizes downtime and provides detailed insights into the performance of the welding system.

Efficient management made easy

- Convenient access: Manage the overall system and all settings conveniently via PC or tablet

- Comprehensive documentation: Get complete data documentation at a glance, with export function

- Signal visualization and system overview: Gives you an overview of all signals and the system

- Efficient job management: Create, compare, and process jobs quickly and easily

- Always up to date: Stay up to date at all times with the latest updates

- Back-up and recovery: Easy backup allows you to seamlessly restore data when replacing hardware

Complete control: the integrated authorization system allows you to assign individual permissions to each user. Thanks to NFC, when someone logs in with a key card or fob, the system immediately knows what they are (and are not) allowed to do. And if you want the perfect solution for assigning and administering authorizations for multiple welding machines centrally, you need look no further than our Central User Management.

Ignition

Stable and reproducible

iWave takes TIG welding ignition behavior to a whole new level. The high frequency ignition process has been optimized and the ignition behavior adapted to the different electrode diameters.

RPI auto*—ignition delays reduced by up to 71%**

Are you looking for a faster ignition process that is fully reproducible—regardless of the material characteristics involved? If so, iWave offers an off-the-shelf solution in the form of RPI auto. The new ignition mode is the next logical step in the development of the proven “RPI on” function. The welding machine now makes changes to the ignition settings automatically, including when it’s necessary to counter deteriorations in ignition—and without any need for manual intervention.

* Only for iWave AC/DC

** Compared to RPI off, test series conducted under laboratory conditions: 200 A welding current | 0.5 s welding time | CrNi | 1000 ignitions

| Evaluation overview | RPI off | RPI on | RPI auto |

| Reproducible ignition | •• | ••• | •••• |

| Lowest ignition delay | ••• | • | •••• |

| Lowest electrode load | ••• | • | •• |

| Gentle action on the weld surface |

•••• | •• | ••• |

Further iWave functions

Tacking

Time savings of up to 50% when tacking materials

Pulse currents are used to make the weld pool oscillate. This makes it easier to tack components together and reduces tacking time, leaving hardly any or no temper colors on the tacking points.

Automatic cap-shaping

in just 2 seconds

Save time: use this function to quickly form a cap based on the set electrode diameter.

Example: Electrodes with Ø 1.6 mm

| Time required (without function): |

91 seconds |

| Time required (with function): |

2 seconds |

| Savings: |

~ 1.5 minutes |

| 8 times per day |

~ 12.0 minutes |

| 5 days/week | ~ 1 hour |

| 40 weeks/year |

~ 40 hours |

Savings: One working week per year and per welder.

The right arc for every application

Weld however you like: for AC welding, iWave allows you to select the waveforms yourself. In other words, the ones that characteristically produce your preferred weld properties for the welding task at hand. If necessary, you can also combine different waveforms.

Waveforms:

Pulses

Standard range of functions

- Pulse current setting

- Pulse frequency setting

- Pulse frequency up to 2 kHz

Extended range of functions with OPT/i Pulse Pro

- Base current setting

- Duty cycle setting

- Pulse frequency up to 10 kHz

- DC waveforms

Automatic gas post-flow

Protection for the tungsten electrode

Welding without oxidation: to achieve this, iWave provides a gas shield for the tungsten electrode and the weld. The gas post-flow time is calculated automatically, depending on the set welding current and the electrode diameter.