Welding protection

Welding fume extraction, welding helmets and Co.

Stresses and hazards

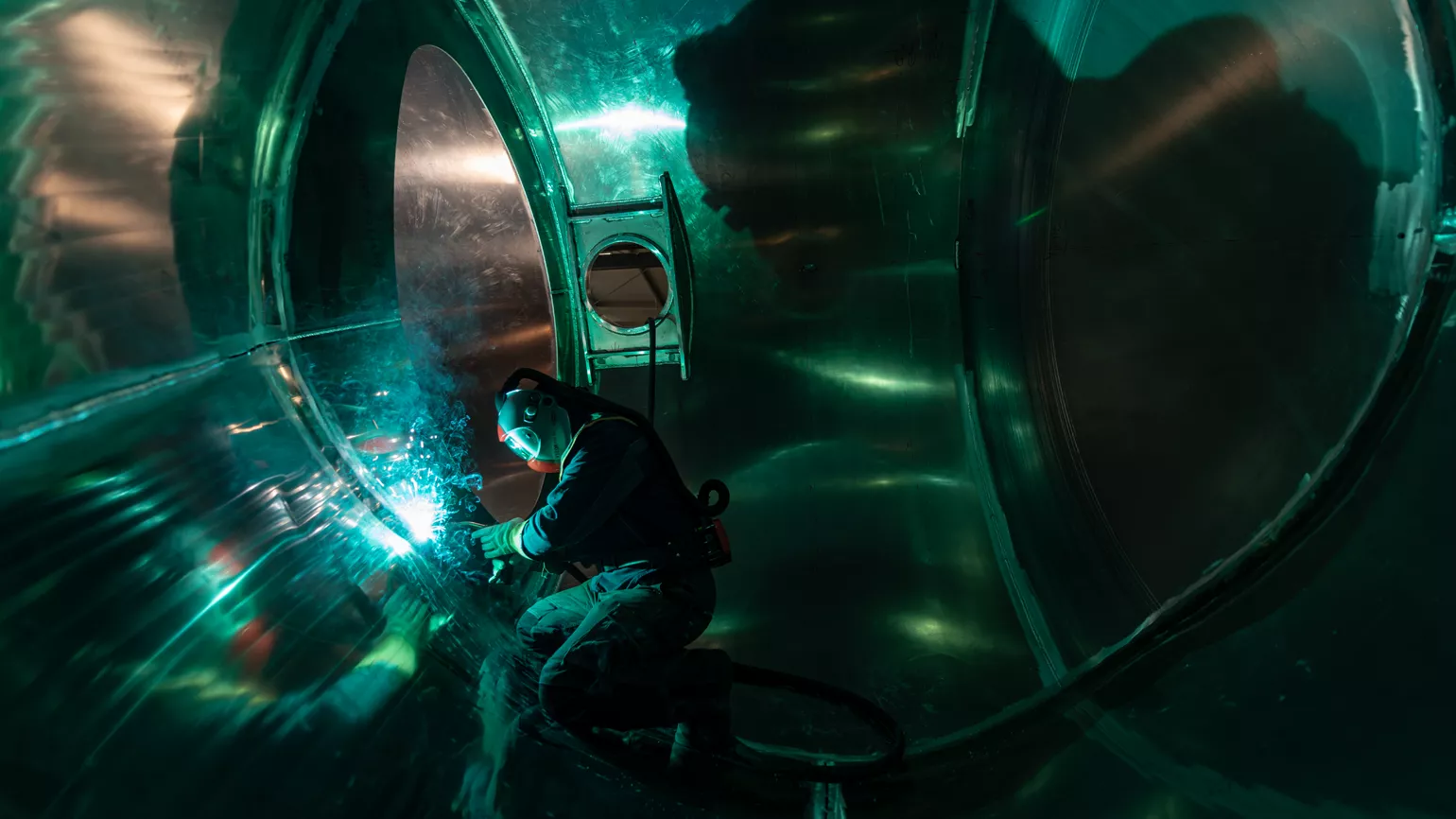

All types of manual arc welding result in varying degrees of exposure to welding fumes, spatter, or UV radiation, so it is particularly important to choose the right protective equipment.

Modified process variants, such as PMC (Pulse Multi Control), LSC (Low Spatter Control), and CMT (Cold Metal Transfer), offer significantly lower spatter and welding fume formation. Lower spatter reduces the need for additional grinding work that can release additional fine dust particles.

The lowest health risks for welders come from automated welding processes, which are implemented in correspondingly equipped welding cells such as Cobot.

Welding processes

| High welding fume formation and spattering |

MIG/MAG welding The varied application areas and different process variants of MIG/MAG welding increase the danger of welding fumes,UV radiation, welding spatter, etc. As MIG/MAG is one of the most common welding processes worldwide, particularly effective protection measures must be used to protect the welder. |

|

| High welding fume formation and spattering |

Stick welding Electrical current and heat, UV radiation, and, above all, increased welding fume formation are everyday risks during manual arc welding. The type of hazardous materials in the welding fumes is crucially dependent on the material of the electrode and itscoating. |

|

| Low welding fume formation, absolutely spatter-free |

TIG welding A relatively small amount of visible welding fumes is produced from TIG welding. This low fume formation, in conjunction with the often highly reflective surfaces of the parent material—usually stainless steel or aluminum—results in an increased spread of the UV rays. The result is increased ozone formation, often at some distance from the welding point. |

|

| Low welding fume and UV exposure |

Cobot welding cell The Cobot welding cell is a simple way to get started with automated MIG/MAG welding. The welding process is completely automated and performed without any welding personnel. The protective enclosure with automatic glare protection and integrated extraction provides optimal protection against UV radiation, welding spatter, and welding fumes for people standing near the welding cell. |

Welducation simulator

Saves resources and protects the health of training personnel and apprentices. Virtual MIG/MAG, TIG, and stick welding can be an important part of the welding apprenticeship.Welding and health

Full protection to unleash your welding potential

Welding is one of mankind’s oldest and most traditional joining processes and it is hard to think of life without it, particularly in industry and trade. The aim is to find ideal solutions for a wide range of materials. In order to do so, however, important factors like metallurgy, physics, and electrical engineering must be taken into account.

It is precisely this interaction that makes welding such an exciting yet challenging trade. Because alongside all the possibilities, there are also health risks, against which we want to protect all welders adequately and sustainably.

Important protection areas:

- Protection against welding fumes:

A major goal is to protect against serious welding fumes and prevent respiratory diseases. In 2017, the WHO’s International Agency for Research into Cancer (IARC) classified welding fumes as “carcinogenic for people”

- UV and glare protection:

Protects eyes and skin against carcinogenic radiation and dangerous injuries

- Flame and heat protection

Reduces health risks due to heat, sparks, or welding spatter

- Ergonomics

Designed for low fatigue welding that is gentle on the joints over long periods of time.

Welding fume protection

Why is this so important?

All welding processes produce fumes, gases, and vapors that affect the welders. How harmful the released welding fumes are depends on the combination of welding process, parent material, and filler metals, as well as the protective gas shield.

The filler metals used produce the majority of the welding fume particles. Without adequate protection, welding fumes can cause headaches and nausea, chronic respiratory and lung diseases as well as damage to the nervous system or cancer.

Components of the welding fumes*

Welding fumes consist of particulate and gaseous materials. Depending on the material to be processed, these can have different impacts on the human body.

- Damaging substances for respiratory tract and lungs

iron oxide, aluminum oxide, magnesium oxide, titanium dioxide - Toxic or irritative substances

fluorides, manganese oxides, zinc oxide, carbon monoxide, nitrogen oxides, copper oxide, lead oxide, ozone - Carcinogenic substances

chrome(VI) compounds, beryllium oxide as well as nickel oxides, ozone

*Source: German Federal Institute for Occupational Health and Safety (Bundesanstalt für Arbeitsschutz und Arbeitsmedizin [BAuA]) – German Technical Regulations for Hazardous Substances (TRGS 528)

Download MSG welding study

In this study, you will learn more about the measures to reduce pollutants when using controlled MSG process variants:

Experimental setup | Emission measurements | Welding fume emission rate | Chemical analysis | Exposure measurement | General overview | Discussion and summary

In three short steps you can download this welding fume study.

How to protect yourself from welding fumes

UV and glare protection

Perfect protection for eyes, face, and head

The eyes, face, and head are exposed to harmful UV and IR radiation during the welding process. A modern, automated welding helmet protects the welder against these and other potential health hazards, such as welding spatter and slag particles. Automated welding helmets detect the arc automatically and darken quickly and independently.

Only Bluetooth®-enabled welding helmets are faster and safer. These are darkened by the welding system even before the arc is ignited, and therefore combine maximum safety with the best working comfort.

Eyes flashed while welding

What to do if it happens anyway?

Everyone knows the unpleasant feeling of looking directly into the sun. It is similar with an electric arc - but the radiation here is many times stronger.

A short eye contact with the arc is normally not a problem: The eye is blinded, but does not take any damage and recovers quickly. However, if you look into the arc several times or for a longer period of time, you will permanently damage your eyes - this is called "flashing".

It is not possible to say for sure when this effect begins and how long it takes for the eye to regenerate. As a rule, the discomfort passes after 24 to 48 hours without any long-term consequential damage being to be expected.

Welders often describe the painful sensation of flashing like a "quarry in the eye."

Affected persons are extremely sensitive to light and prefer to keep their eyes closed. An antibacterial ointment from the pharmacy is usually very effective in relieving the pain. In addition, cold compresses are recommended to cool the eye.

Flame and heat protection

Heat-resistant and flame-retardant clothing is essential to protect welders against high temperatures and welding spatter. It is essential that protective clothing retains its properties in tough, everyday welding environments and is protective at all times.

High-quality protective equipment is characterized by:

- Standards-compliant, heat-tested materials

- UV-resistant protection of eyes and body

- Spatter guard at all exposed points

- Functionality and maximum wearer comfort

In addition to clothing, plug-in heat shields and button extensions for the welding torch ensure even better heat protection during all welding tasks.

Ergonomy

More welding comfort for more welding quality

Ergonomics in welding cannot be taken for granted - it supports and protects the welding specialist at work. It is therefore crucial to have solutions that offer not only the important occupational safety but also the necessary working comfort to promote a healthy musculoskeletal system:

A low weight of welding equipment and hose packages, ergonomic and non-slip torch handles, quick changeover options and flexible operating units make the daily work of welders much easier - for healthier welding and better results.