Our TPS/i TWIN Systems

Intelligent Tandem Welding

Tandem welding has never been so easy

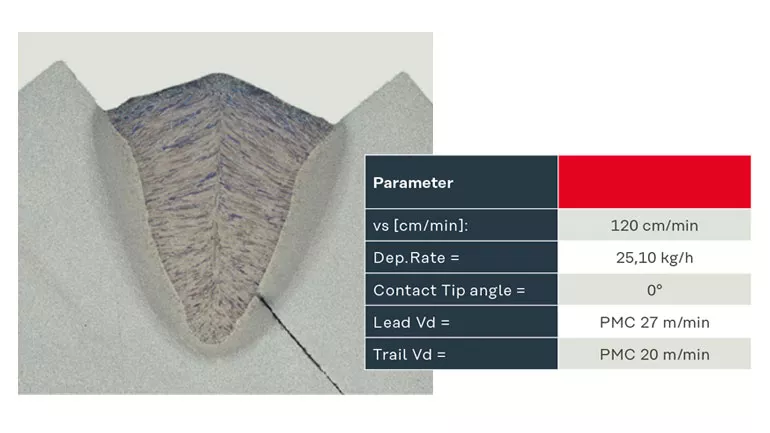

Consistently high welding speed with reliable penetration and deposition rates of up to 25 kg/h—our TPS/i TWIN systems have got you covered.

Our newest development with intelligent welding processes that automatically adjust welding parameters and welding variables in the background provide maximum control and time savings—supported by robot assistance systems and automatic change and cleaning systems.

TPS/i TWIN systems are adapted to the respective application area on a modular basis. Whereas a push system is the ideal solution for steel applications, a PushPull solution is recommended for aluminum. If you want to achieve the absolute maximum when it comes to welding speed and process stability, look no further than the CMT TWIN process.

Self-regulating process

Only adjust the most necessary aspects

Achieve better results automatically: During the welding process, our system regulates the welding parameters and welding variables independently in the background to keep both arcs perfectly regulated at all times.

Smart assistance systems

Support that saves you time

TeachMode, TouchSense, SeamTracking, WireSense and short circuit detection within the gas nozzle: Our assistance systems simplify handling of the welding system and thereby increase welding efficiency.

High deposition rate

Up to 25 kg/h

Processing large, heavy components has never been easier. This is possible thanks to the power of 2 TPS/i power sources in one system, leading to particularly high deposition rates and excellent gap-bridging ability.

High-speed welding

Welding speeds of up to 4 m/min

Fast welding without loss of quality: This is par for the course owing to the high deposition rate—just like the reliable penetration and notch-free welds.

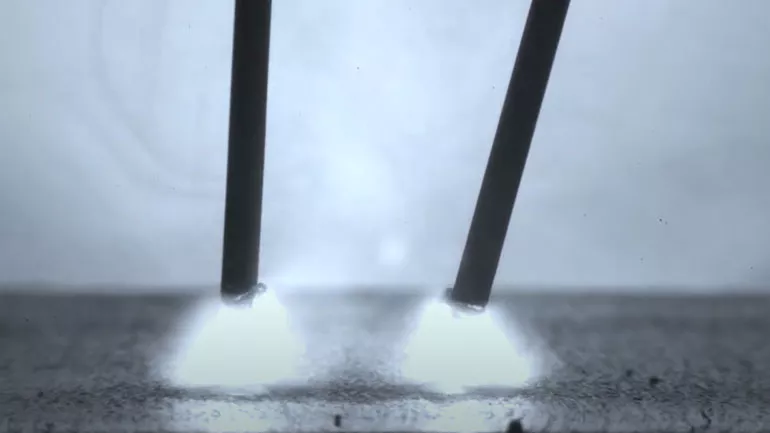

Totally stable welding

Continuous production with a long service life

High level of process reliability thanks to reliable wirefeeding. The highly dynamic TWIN Drive unit and wire buffers ensure, amongst other things, maximum stability.

TWIN systems at a glance

| TWIN PUSH | TWIN PUSH/PULL | CMT TWIN |

|

Welding process: PMC TWIN Field of application: Steel Typical welding tasks: Axles, rims, bogie frames and steel beams |

Welding process: PMC TWIN Field of application: Aluminum Typical welding tasks: Aluminum profiles, carriage construction, containers, pressure vessels, tanks |

Welding process: CMT TWIN and PMC TWIN Field of application: Light gage sheet, aluminum, nickel-based alloys, high-strength steel Typical welding tasks: Axle production, exhaust systems, hydraulic cylinders, mobile crane booms, pressure vessels |

System design

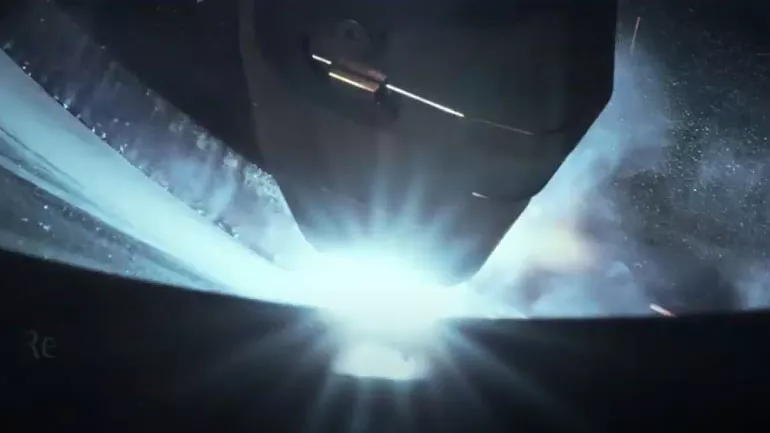

The TWIN welding processes

PMC TWIN

PMC (Pulse Multi Control) is a further development of the pulsed arc from Fronius. It provides the technological basis for the PMC TWIN process and is available with different characteristics as is typical from Fronius.

As a result, the right process properties can be accessed directly depending on the application scenario.

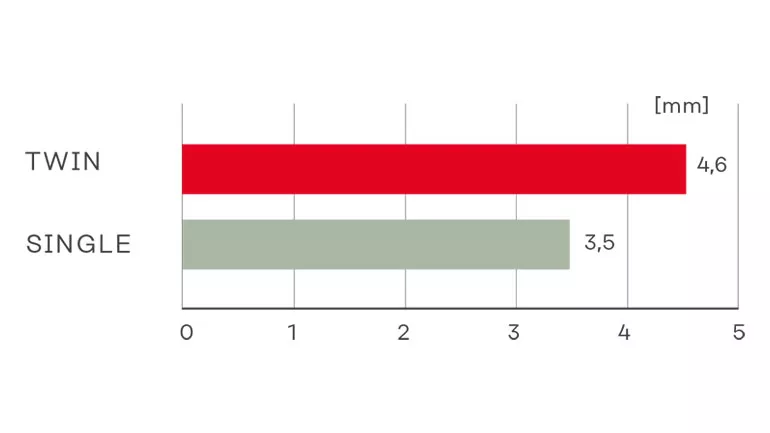

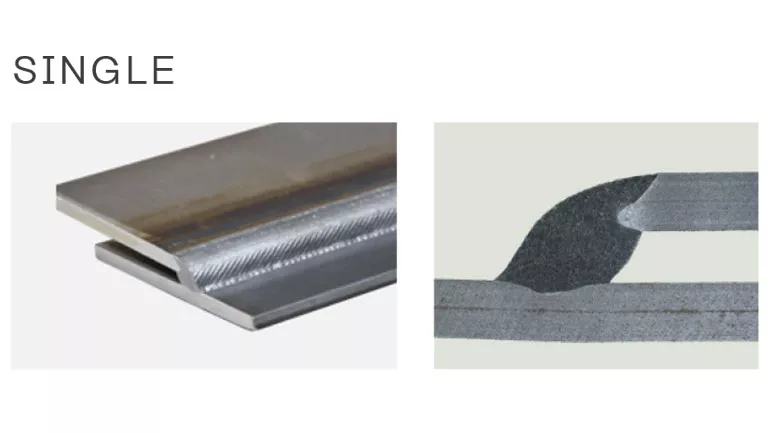

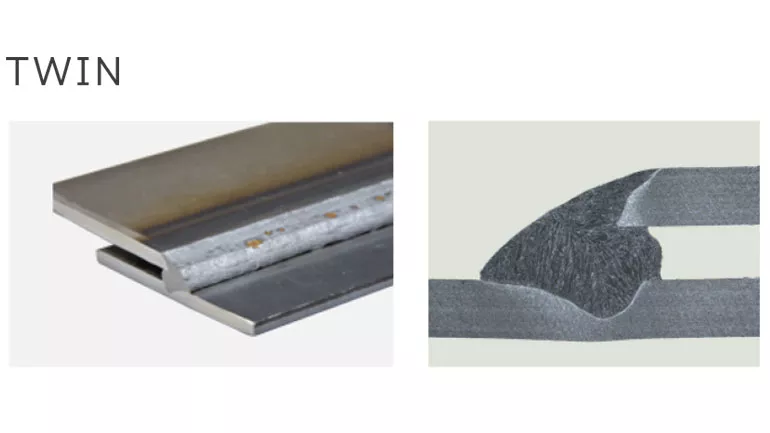

Reliable penetration

Achieve the desired weld quality with maximum reliability:

With the TWIN process, even greater penetration is achieved despite its tremendous speed.

High deposition rate

One weld is enough: Thanks to the high deposition rate of the TWIN system, welds that require multiple layers are a thing of the past.

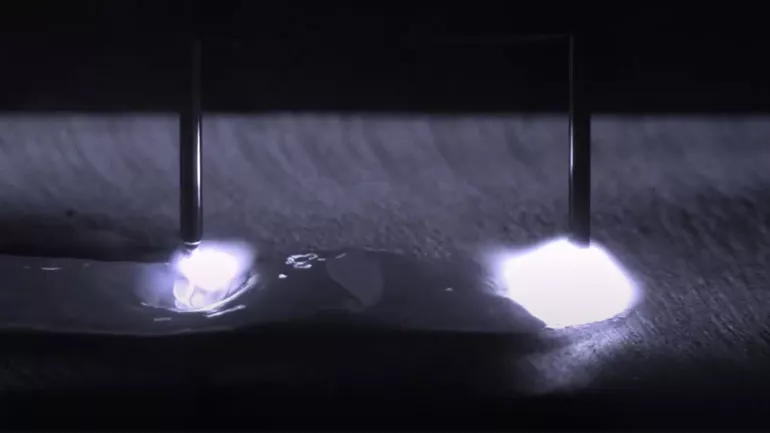

CMT TWIN

CMT (Cold Metal Transfer) is a welding process developed by Fronius that provides the technological basis for the CMT TWIN process.

By combining different processes, benefits such as high speed, a gap-bridging ability and few spatters are brought together in one process. The process is also available with different characteristics to ensure users have the right process properties for their application at their fingertips.

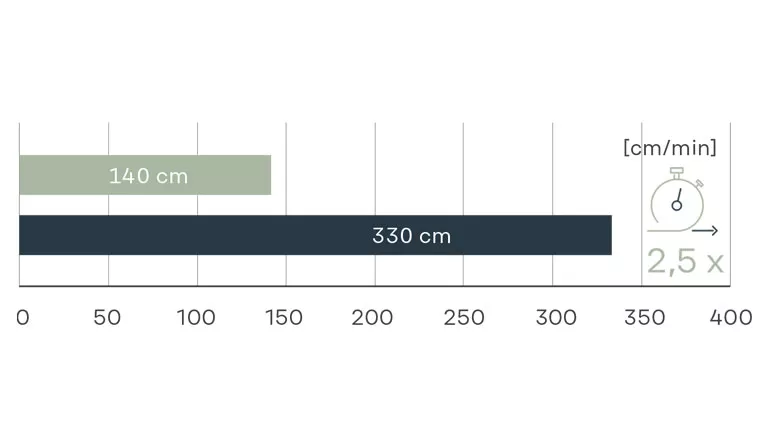

Achieve the perfect result at top speed

Reliable penetration without notches: Thanks to the high deposition rate, the tandem process enables speeds of up to 330 cm/min. This allows you to weld 2.5 times faster than with just one arc.

Gap-bridging ability

Four times the welding speed and optimal gap-bridging ability with TWIN welding despite a 3 mm gap!

Our assistance systems at a glance

TeachMode

For efficient programming of welding positions on the robot: The wire is pulled back before it collides with the component, thus preventing the wire from bending. The set stick-out always remains the same.

SeamTracking

Compensates for clamping and component tolerances during the welding process, thus preventing welding errors and unnecessary rejects.

WireSense

Reduces time-consuming reworking: The wire electrodes measure component deviations such as varying air gaps or clamping tolerances and transmit the values to the robot.

TouchSense

Developed for welding fillet welds and processed butt welds; the wire or gas nozzle precisely scans the component and transmits the start and end position to the robot, which calculates the exact seam path.

ShortCircuitDetection

The welding system detects accumulations of welding spatter inside the gas nozzle. Cleaning routines can be optimized and process reliability can be increased.

Slaghammer

Safe and clean start to the welding process: Before welding, slag that has formed during previous welds is knocked off by reversing wire movements.

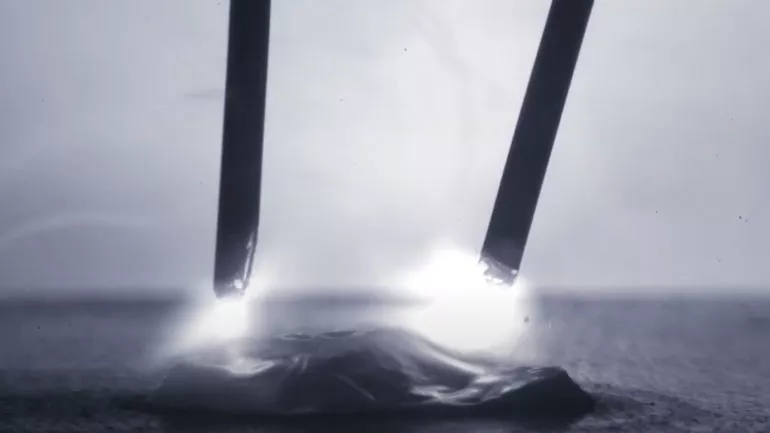

SFI—Spatter-free ignition

Spatter-free ignition with SFI enables safe and clean ignition.