Robot welding torch

For TIG welding applications

Your complete solution with Fronius TIG robot welding torches

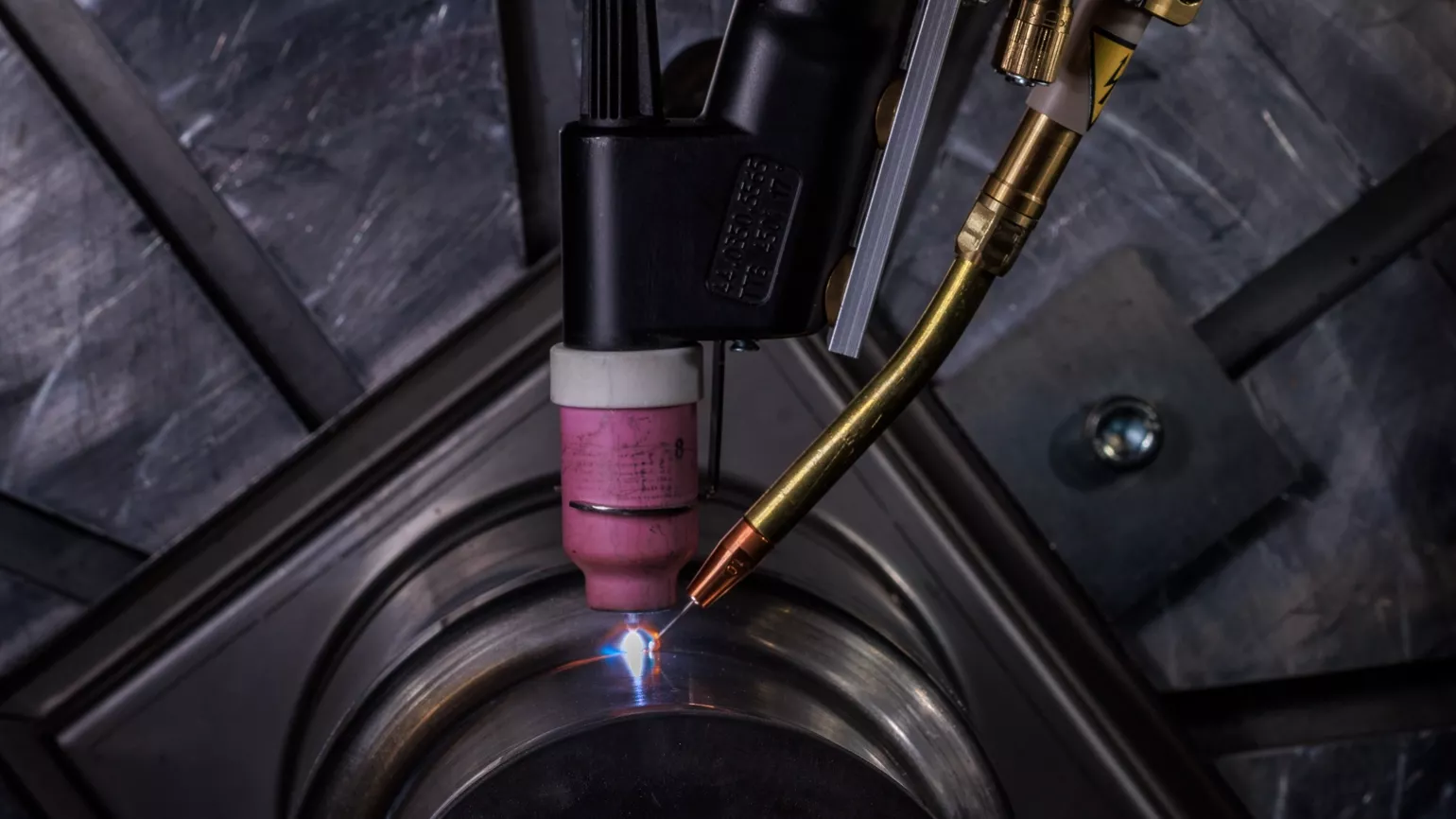

From initial ignition to the final seam, our TIG robot welding torches offer high-performance solutions that can be easily adapted to your specific production requirements.

The highest levels of precision, even with demanding welding tasks: torch bodies in various lengths and angles can tackle complex component shapes and difficult-to-access areas with ease. Whether in the automotive sector or in plant construction – our torches will help you optimise process lead times, reduce wear, and ensure a smooth production process. Benefit from durable quality and superb performance when processing stainless steel, aluminium, and other metals.

Advantages of our TIG robot welding torches

Quick and easy replacement of the torch body

using the quick-release coupling integrated into the hosepack.

Huge range of options

We have the perfect robot welding torch for every welding application.

Reduce costs

with wear parts that perfectly complement the respective material and application.

Easy integration

into existing robotic systems for a quick and efficient start to the automation journey.

Integrated pilot arc

for uniform and reliable ignition.

Optimal cooling of the torch body

increases the service life of wear parts.

Accessories and components

for customised complete solutions and different applications.TIG robot torch systems – the perfect solution for every application

To provide even more flexibility and improved accessibility, the “i” and “s” series torch bodies are available in eight different sizes and geometries – ideal for complex applications. This wide choice guarantees maximum adaptability and seamless integration into your welding processes.

- You only need one hosepack for a range of different torch bodies.

- Torch bodies are available in a range of angles and power categories.

- The TCP accuracy of the torch body is +/- 0.8 mm.

- Cooling of the torch bodies has been improved by increasing the water flow rate.

For robotic applications

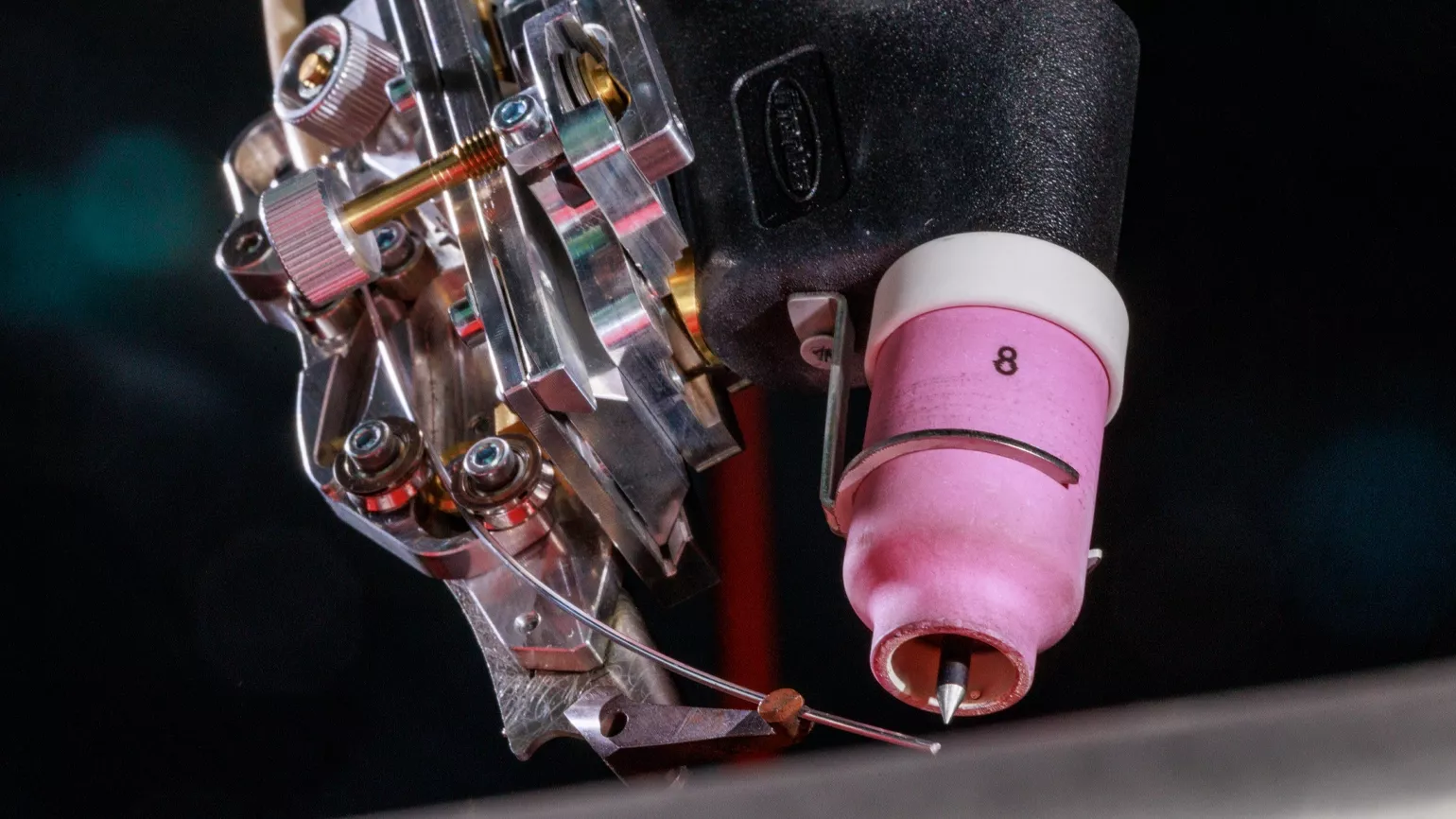

TIG torch body “i”

- Six torch bodies in a range of shapes and sizes

- Integrated connection for trailing gas and water cooling

- Detachable wirefeed

- Suitable for hollow-arm robots and conventional robotic applications

- Integrated BID (welding torch ID) for detection and tracking during the production process

TIG torch hosepack “i”

A particularly high degree of efficiency is achieved through the use of an internal wirefeeding hose for hollow-arm robot systems. The four buttons integrated on the hosepack permit intuitive control, while the status LED provides immediate feedback on the operating status. The direct control of important functions – such as forwards/backwards movements of the wire, gas flow/gas test, and cooling circuit on/off – means that operation from the power source is no longer necessary.

Push system (hollow arm/conventional)

For conventional robotic and mechanical applications

TIG torch body “s”

- Two torch bodies in a range of shapes and sizes

- Ideal for conventional robots, mechanical applications, and cobot cells

Torch hosepack “s”

The “s” series TIG hosepack is designed specifically for conventional applications. It is characterised by its ruggedness and flexibility. It offers reliable performance for mechanical applications and supports all the functions necessary for efficient, standardised welding processes.

- Robust TIG hosepack for conventional applications

- Ideal for mechanical processes

- High reliability and flexibility for simple welding tasks

Push system (mechanical/conventional)

Functions and application areas at a glance

| Functions and applications | Welding torch i | Welding torch s | |||

| Quickly replaceable torch body The easy-to-change torch body enables the welder to switch flexibly between various torch body geometries using a single hosepack. |

X | X | |||

| Integrated torch body ID (BID) The identifier integrated in the torch body permits the continuous detection and tacking across the entire production process. |

X | ||||

|

Integrated trailing gas connection |

X | ||||

| Control buttons directly on the hosepack The four buttons on the hosepack enable important functions such as forwards/backwards movements of the wire, gas flow/gas test, and cooling circuit on/off to be controlled directly. |

X | ||||

| Status LED The Status LED indicates the present operating status directly on the hosepack, enabling messages to be read quickly and reliably in all situations. |

X | ||||

| Compatible with hollow-arm robots The flexible mounting options for hollow-arm robots allow TIG robot torches to be used with a wide range of different types of robot. |

X | ||||

Accessories and components

For customised complete solutions and different applications

Cold-wire feed “Standard M”

- Slimline design for a clear view of the weld pool

- Mechanical locking for constant wire position and stable wire feeding

- Easy handling when changing the gas nozzle

- Can be locked in place at any angle

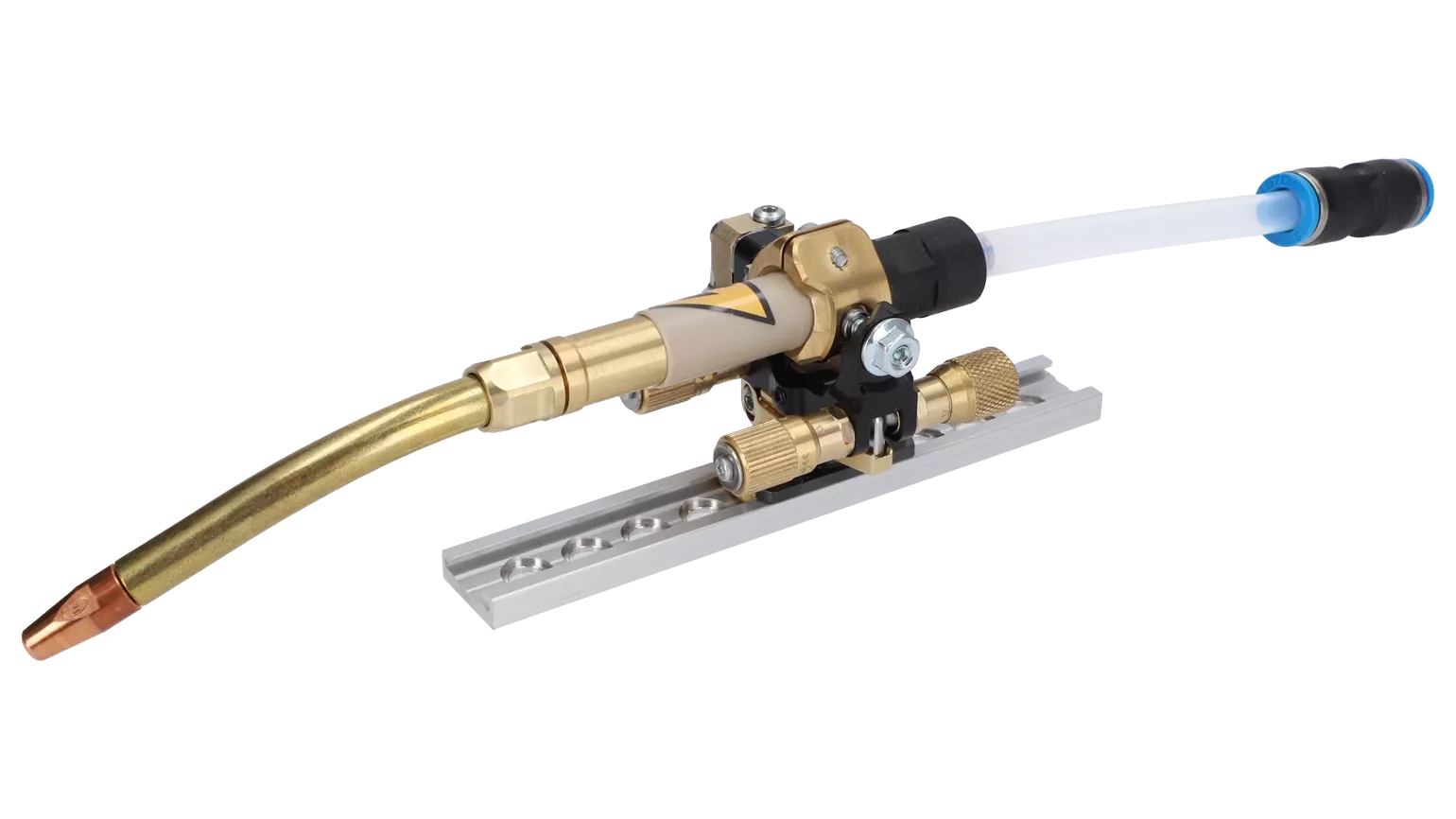

Cold-wire feed “Standard R”

- Slimline design for a clear view of the weld pool

- Adjustment mechanism positioned along the guide rail

Cold-wire feed “Low Friction”

This cold-wire feed is ideal for welding tasks that require a steeper and shallower wire feeding angle.

- Welding torch angle adjustable according to the application

- Fine adjustment possible for precise applications

- Can be retrofitted and removed

- Mountable on standard torch bodies

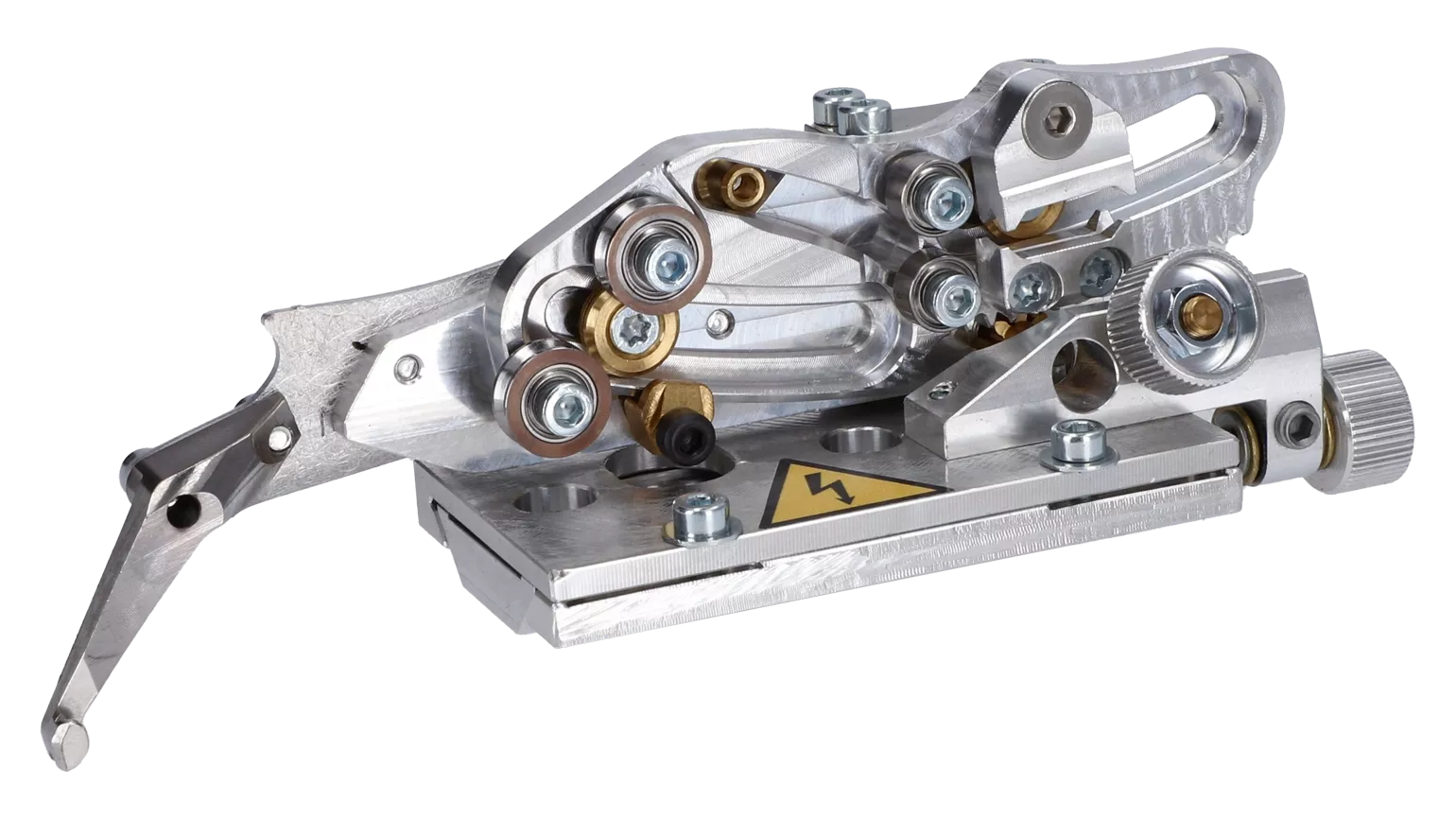

Spring-loaded CrashBox – maximum protection for your welding torch

In the event of a crash, the new spring-loaded CrashBox technology with multi-directional triggering (+/- X, +/- Y, +/- Z) – including negative Z – enables the spring-loaded thrust bolts to be deflected so that after just a couple of millimeters of travel they no longer exert any force on the torch body.

This complete triggering across all axes guarantees even higher levels of protection and prevents damage to the torch – regardless of the direction of the collision.

Tungsten Fast Clamp (TFC) electrode change in just two steps

The “Tungsten Fast Clamp” system is compatible with the TTB 450 robot welding torch and allows the electrode to be changed quickly.

- The electrode can be changed quickly and easily in just 5–7 seconds

- Constant clamping of the electrode as result of defined spring force – stable even over long welding times

- Prevents damage caused by tightening the torch cap too tightly or not tightly enough

- Ideal for electrodes of up to 1/8 inches in diameter and 6 inches in length