Highest welding speed with LaserHybrid

Fronius LaserHybrid, the laser-MIG welding process from Fronius, combines the advantages of the industrial-scale MIG and laser-beam welding processes, without inheriting the disadvantages. Fronius LaserHybrid offers the excellent gap-bridging ability and easy weld-seam preparation of MIG welding, as well as the low heat input, deep penetration and speed of laser welding. This enables the automated joining of various aluminium and steel components at a speed of up to 8 metres per minute, in superlative quality.

The synergy effects of the Laser and Arc increase process efficiency

Laser |

Arc |

| / Deep penetration | / Low-cost energy source |

| / High welding speed | / Gap-bridging ability |

| / Low thermal load | / Addition of filler metal |

| / High strength | / Influence on the structure |

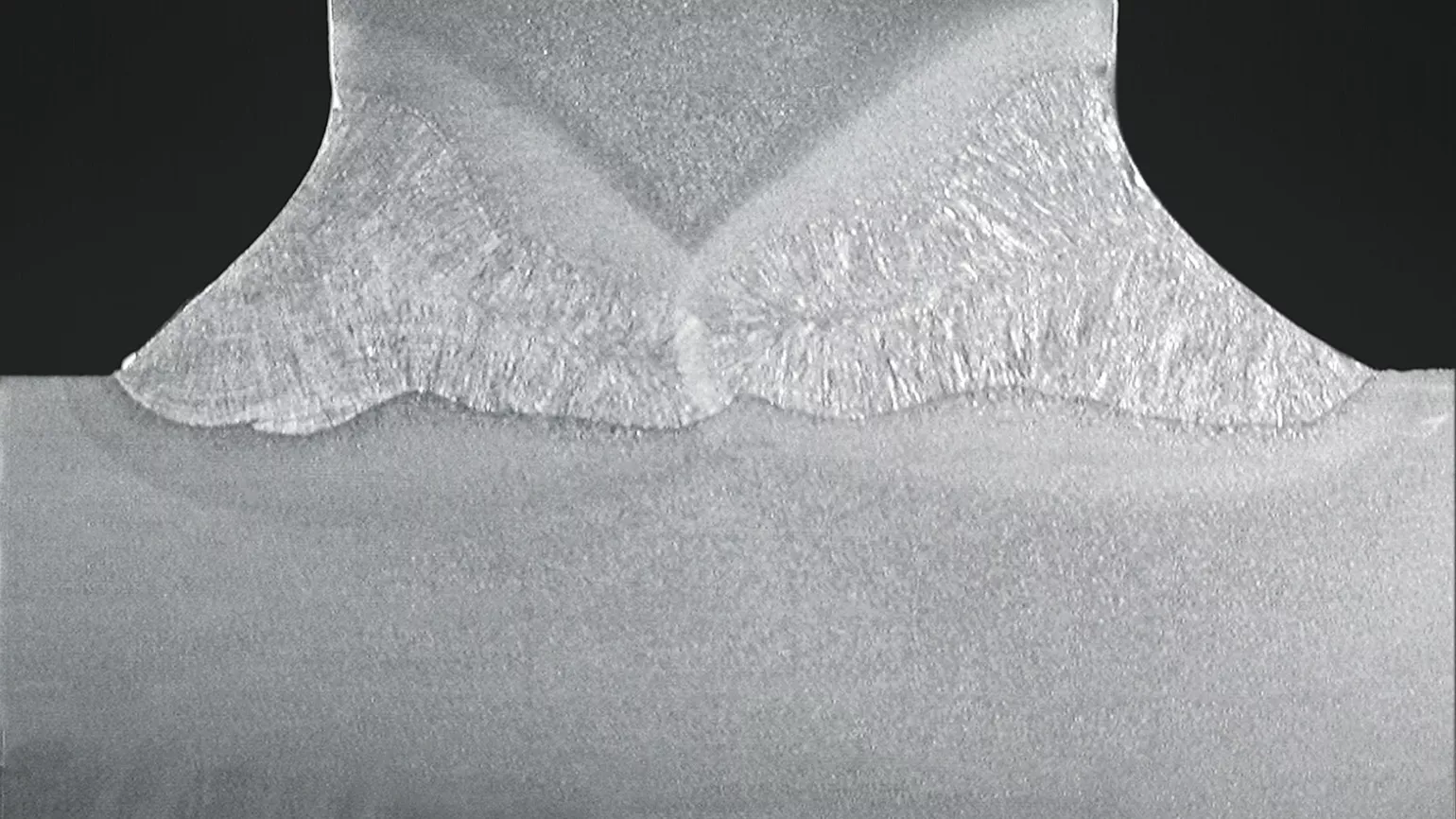

The advantages combined:

/ higher process stability

/ higher welding speed

/ good flow from weld seam flanks

/ large weld volume

/ good metallurgical properties

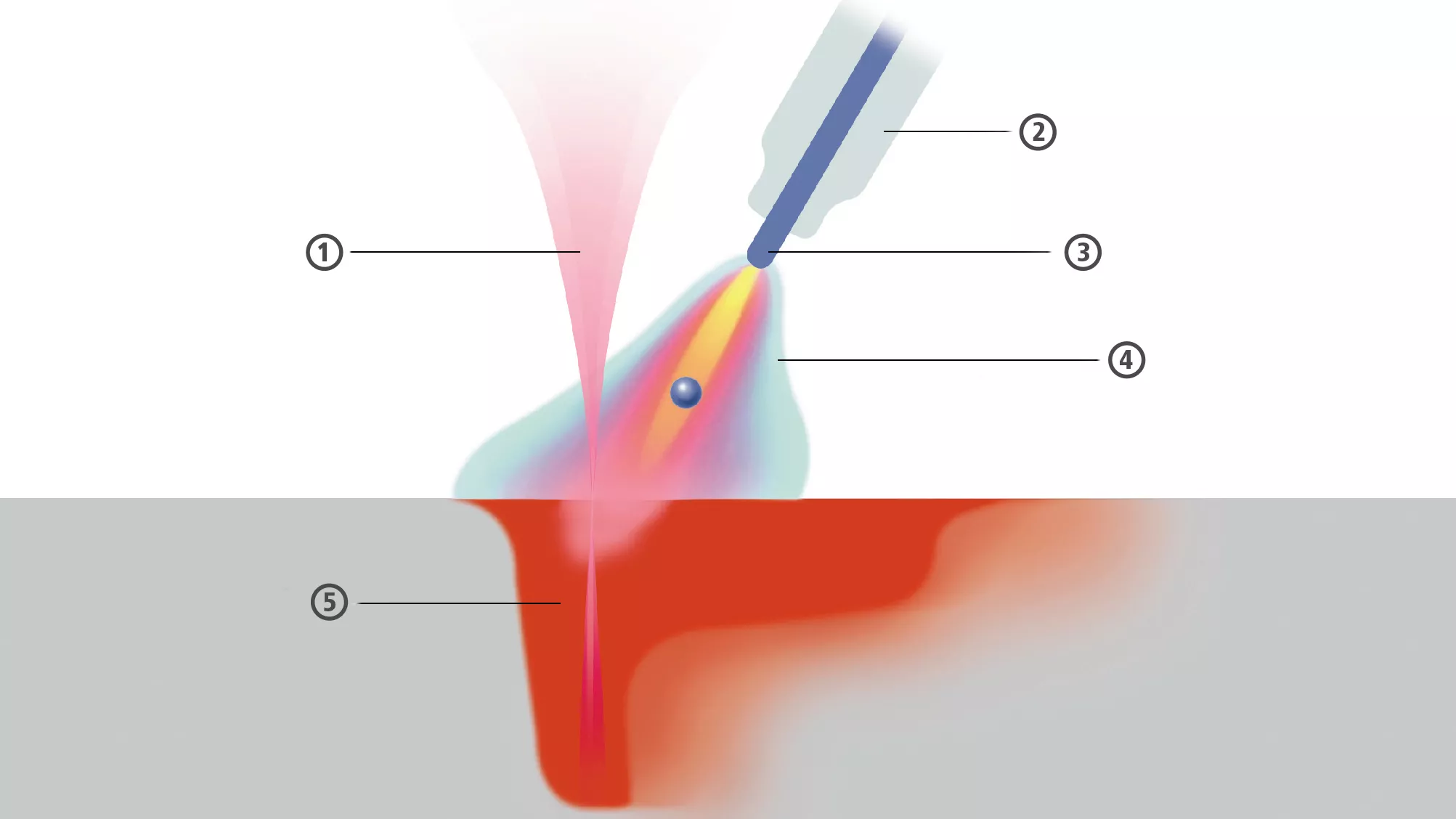

1 Laser beam

2 Gas nozzle

3 Electrode

4 Pulsed arc

5 Penetration

Downloads

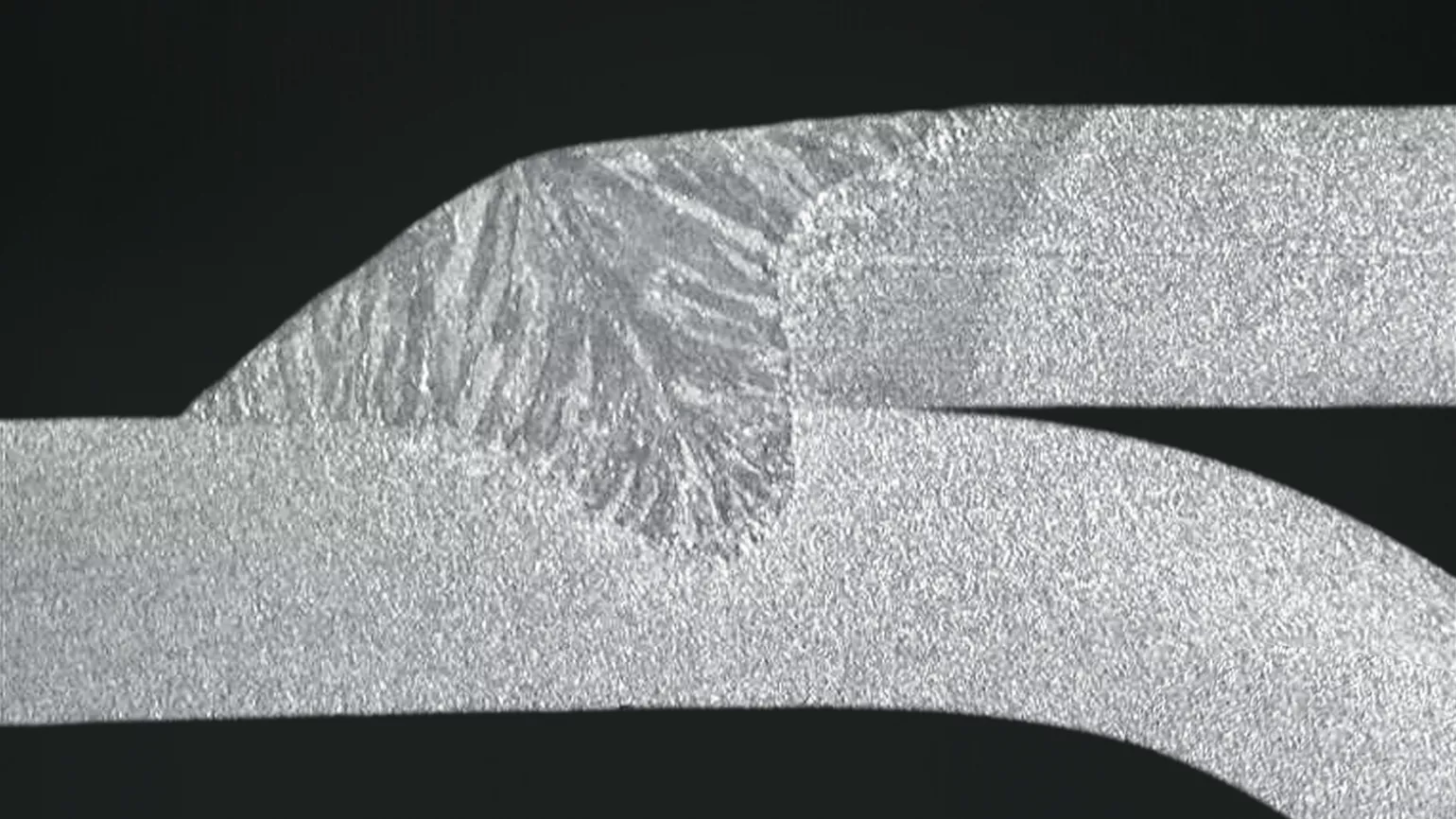

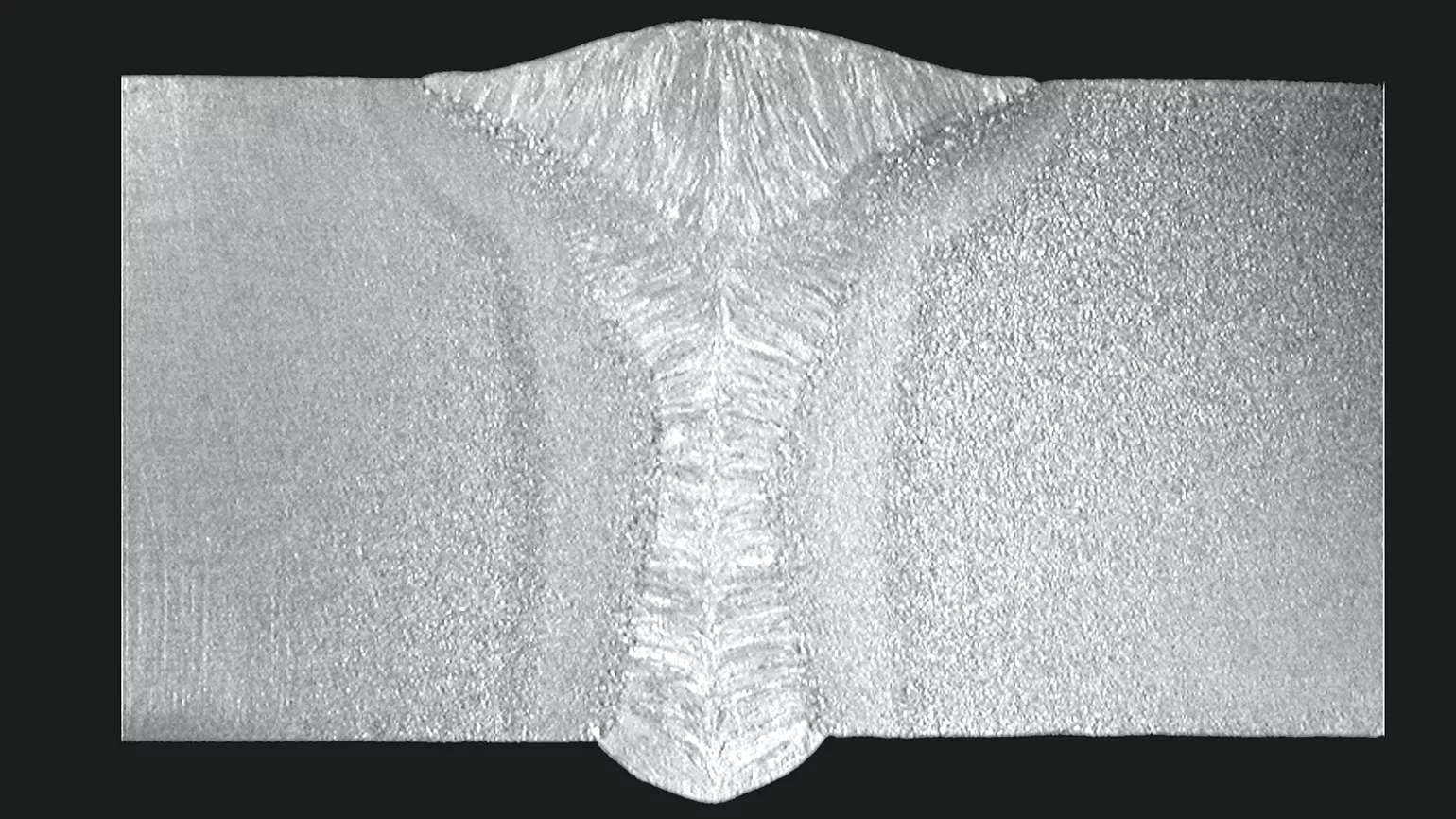

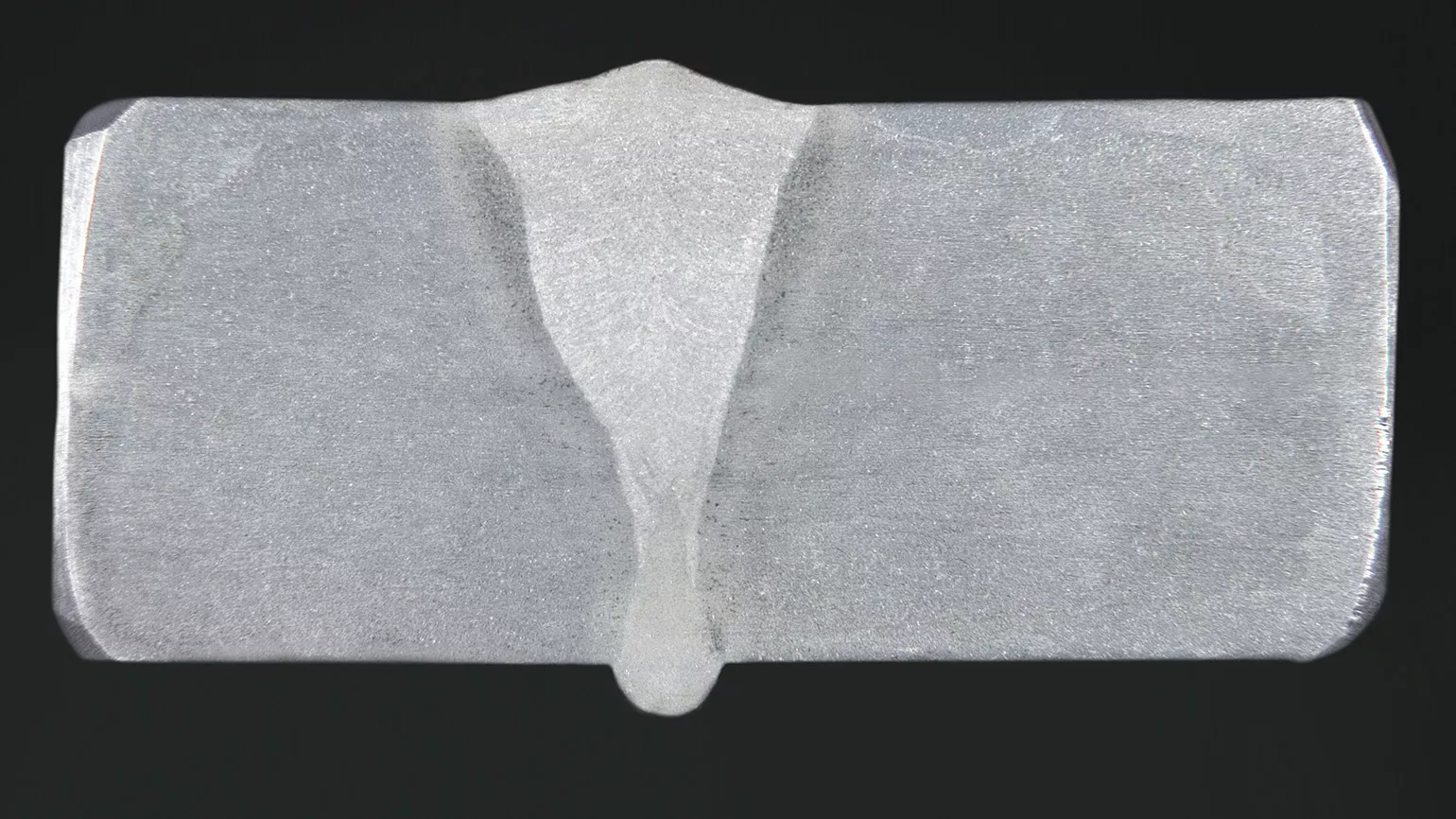

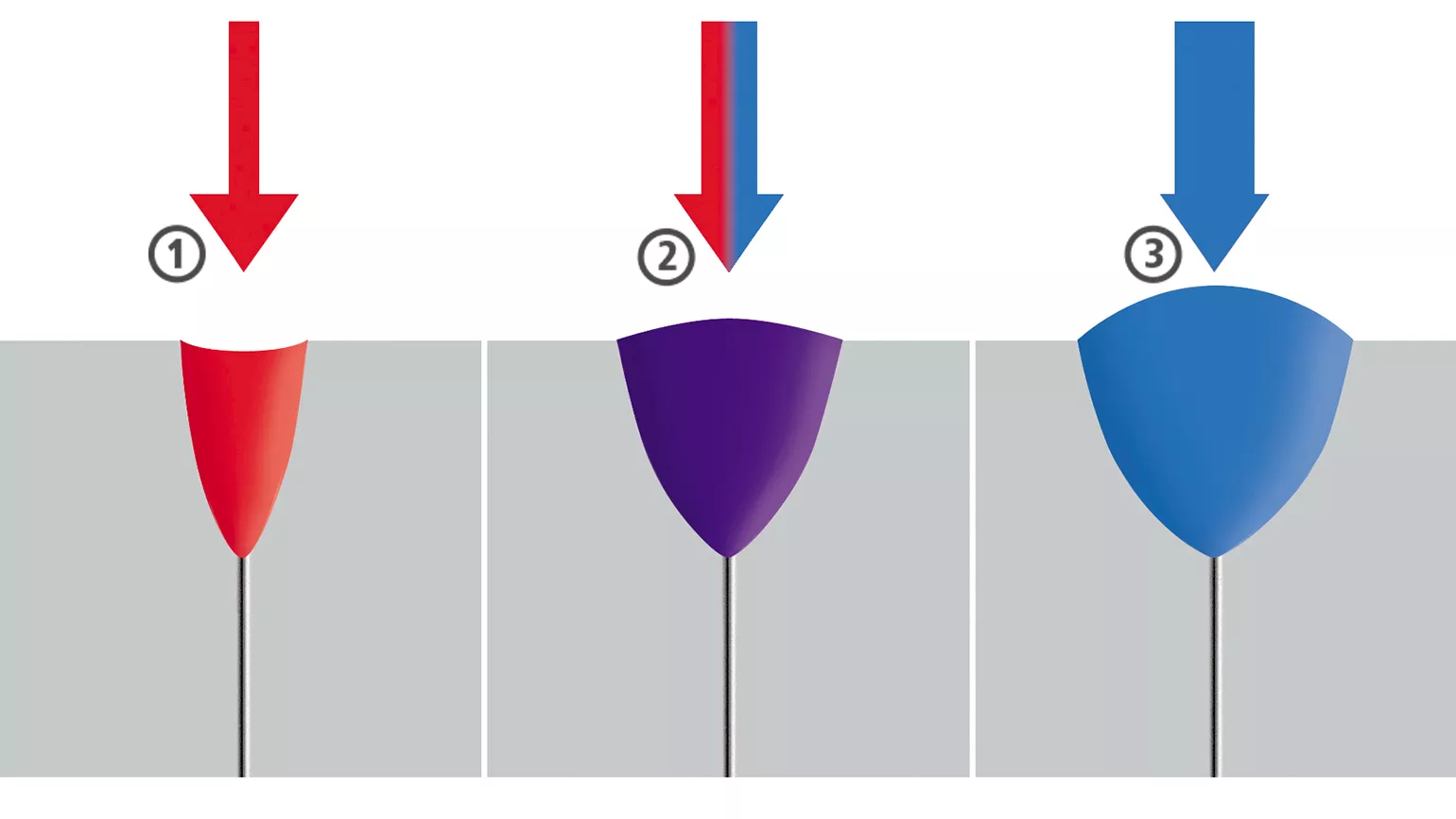

| 1 Laser | PL (laser power) = 2000 W |

| 2 LaserHybrid | PL (laser power) = 1500 W / Vd= 5.5 m/min |

| 3 MIG | Vd = 11 m/min |

|

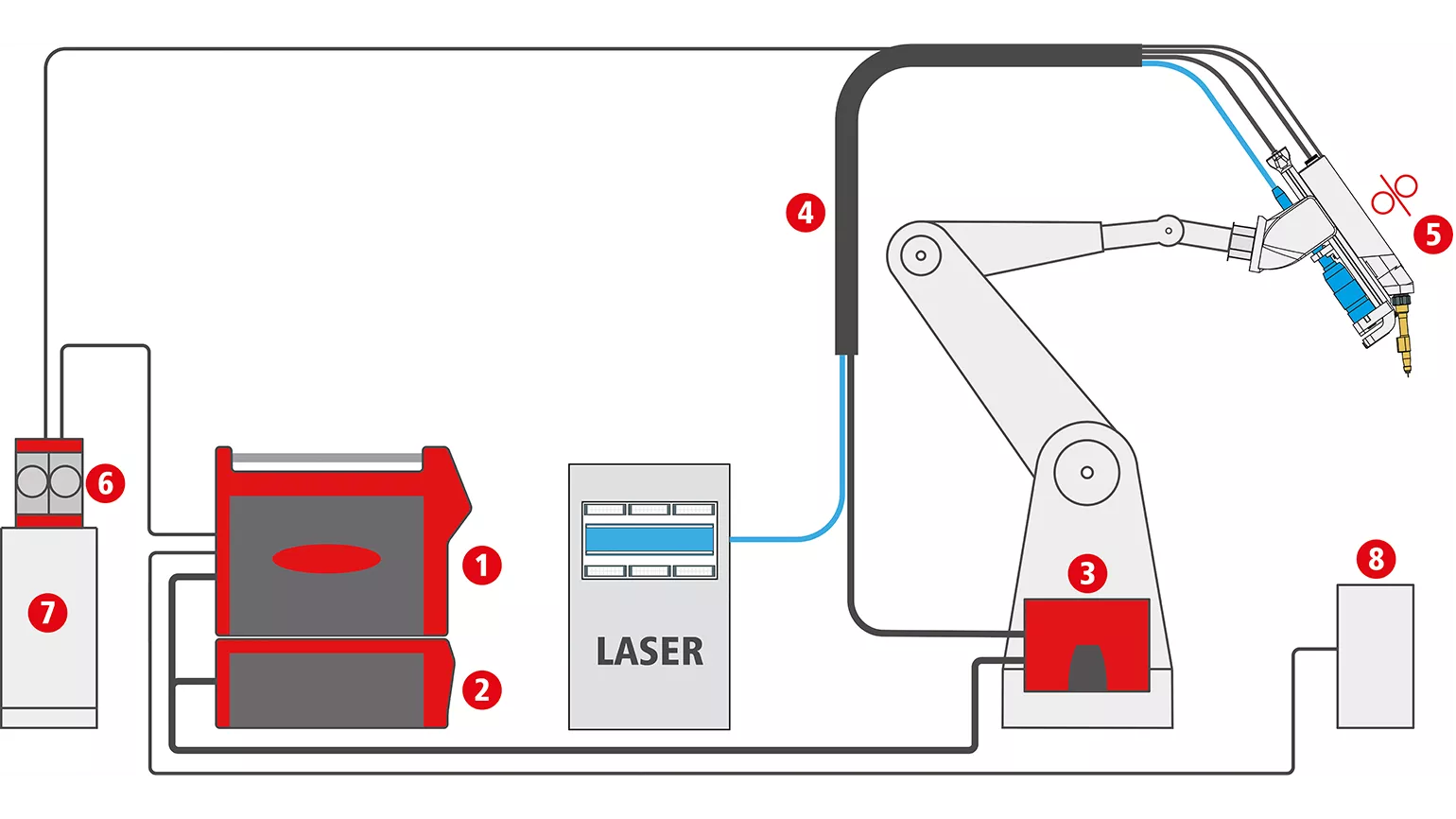

System components |

1. TPS/i 2. Cooling unit 3. Splitbox 4. Torch hosepack 5. LaserHybrid welding head 6. Wire feeder 7. Wire barrel 8. Cleaning station |

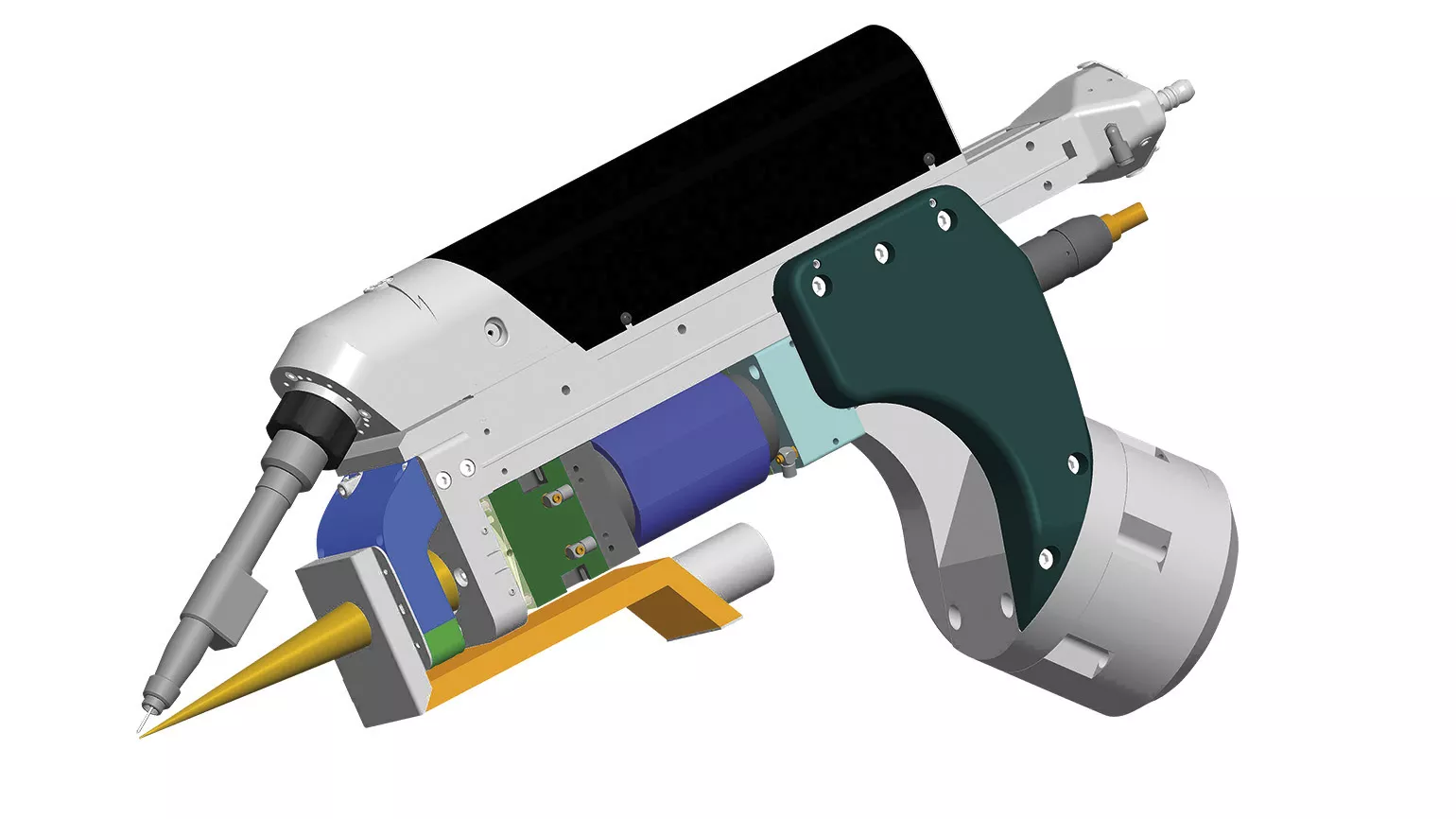

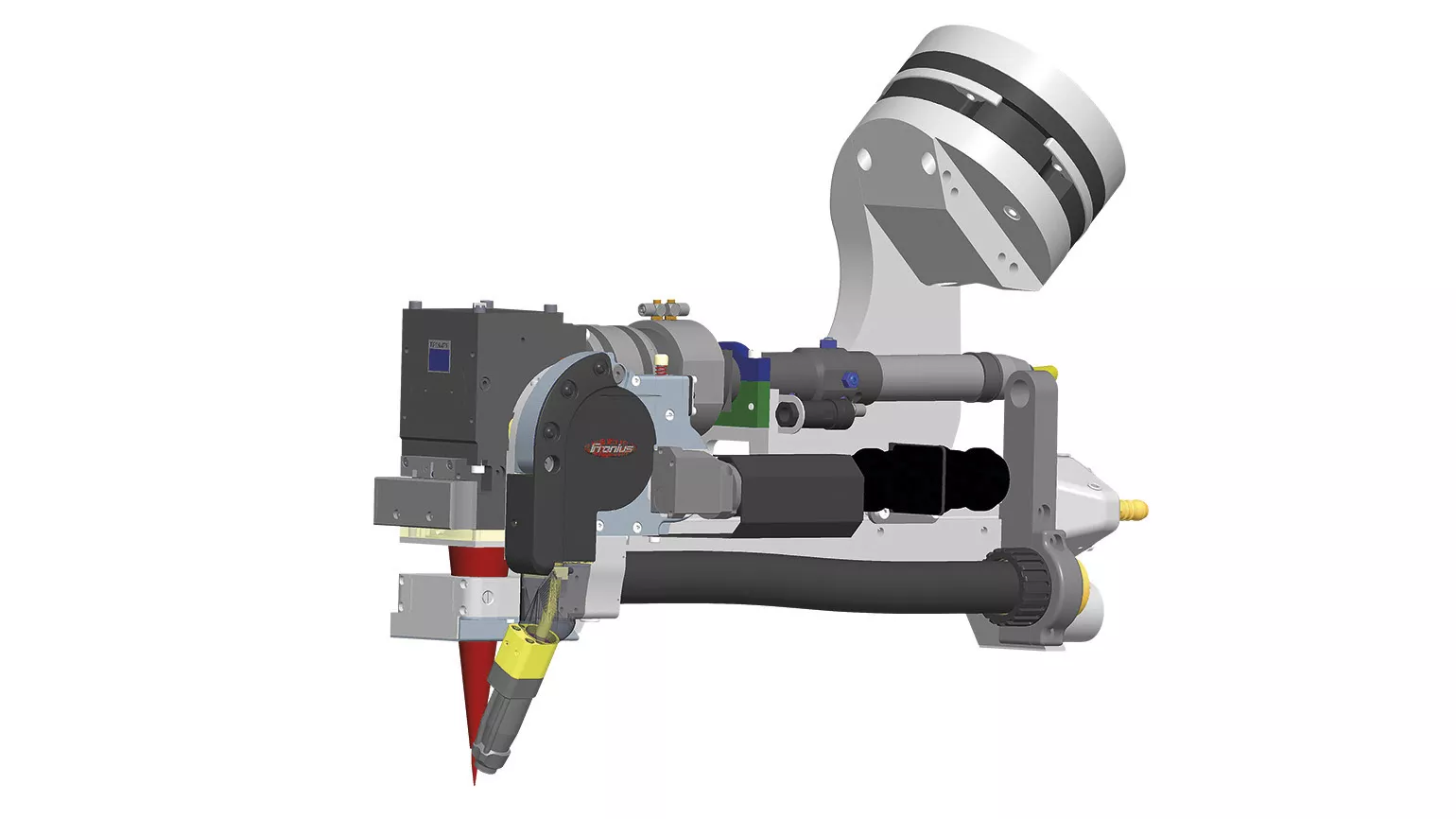

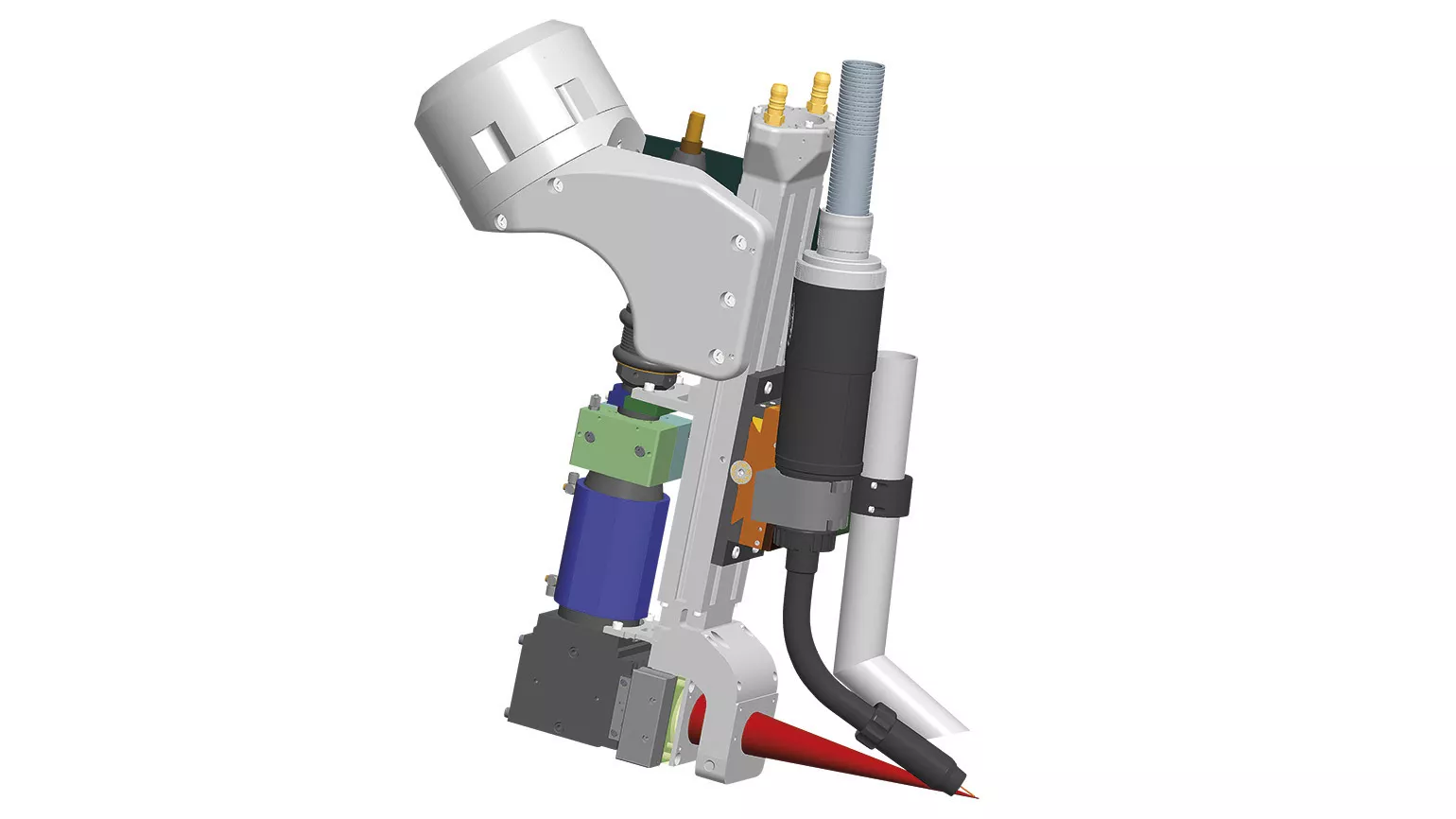

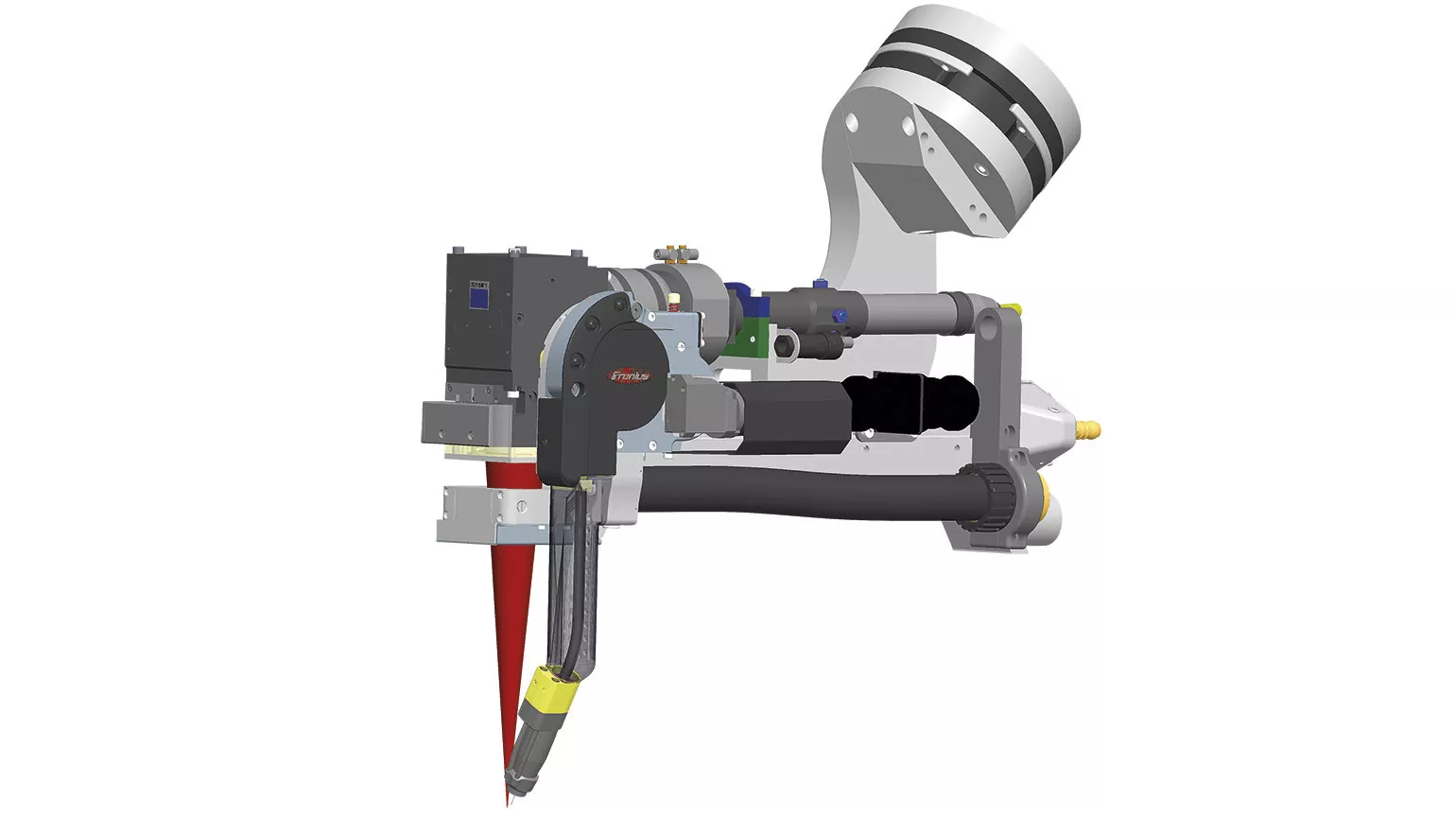

LaserHybrid welding head

At the heart of the LaserHybrid welding system is a compact LaserHybrid head with an integrated MIG/MAG welding torch and laser optics. A robot holder connects the LaserHybrid head to a standard industrial robot. This gives the LaserHybrid head the flexibility it requires to access difficult-to-reach areas of the workpiece. The welding wire can be placed in any position with respect to the laser beam, enabling the joining process to be adapted precisely to the wide variety of weld-seam preparations, outputs, wire types, wire grades and joining tasks.

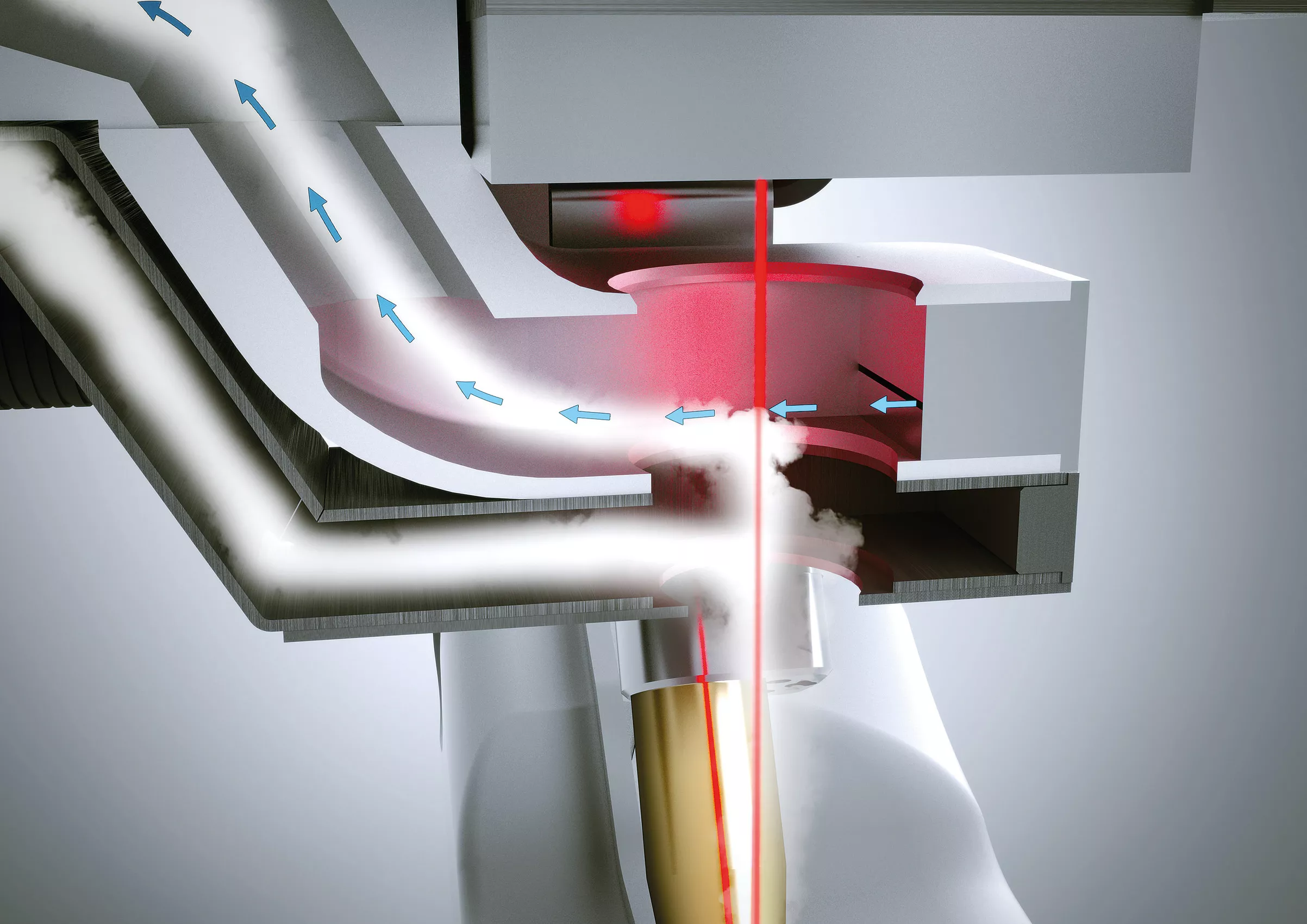

CROSSJET – innovative protection of the laser optics

Coated protective glass is required to protect the laser optics from welding spatter damage. The LaserHybrid head uses a Crossjet unit to ensure that the protective glass itself remains clean, undamaged and transparent for the laser. The air flow effectively diverts any spatter into an extraction channel at a supersonic speed. The air flow itself is also extracted before it can reach the weld area and interfere with the work of the shielding gas. The processing cell also remains free of contaminants and welding fumes. The integrated MIG/MAG welding torch has a dual-circuit cooling system and draws its welding current from a fully digitised inverter power source, which also controls the wirefeeder.