Cladding

Chemical load, wear and corrosion cause problems for metal components. Using overlay welding of additional special alloys, also known as cladding, however, components can be protected and therefore their service life can be increased. This is a technologically challenging process. Fronius offers modern systems and tailored welding processes for this purpose, which help the user to ensure the necessary high level of quality.

Compact Cladding Cell – Advantages

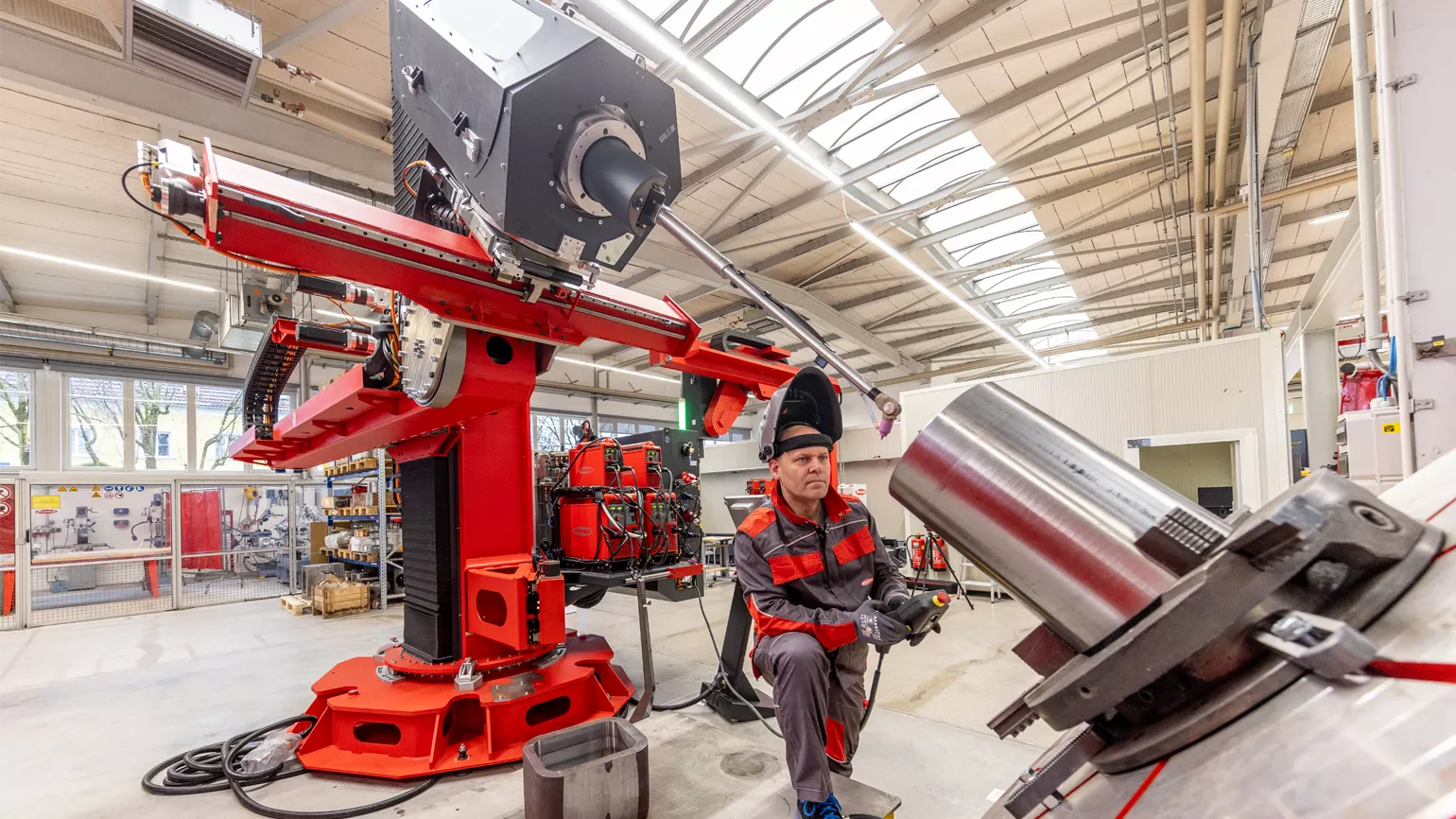

System Overview – Compact Cladding Cell (CCC)

ETR-S Advantages

- Synchronized movement axes allow for the welding of complex component shapes

- Considerably reduced setup times due to automatic determination of the component position in the 3D space

- SpeedClad 2.0 compatible – up to three times better cladding performance in comparison with conventional TIG HD welding processes

- HMI-T21 system controls – the new generation of control with an expanded scope of functions

System overview ETR-S HMI-T21

ETR Ultimate Advantages

High-end cladding system

- Expanded working area due to motorized track

- Complex component shapes

- Multi station operation (fully automated)

- Synchronized movement axes

- SpeedClad 2.0 compatible HMI-T21 system controller

System Overview ETR Ultimate

Conventional Cladding System Advantages

/ New control and drive technology for an even more precise cladding process

/ Motorized tiltable welding torch axis (up to 90°) to comply with the optimum weld layer

/ SpeedClad 2.0 compatible – up to three times better cladding performance in comparison with conventional TIG HD welding processes

/ HMI-T21 system controls – the new generation of control with an expanded scope of functions

System Overview Conventional Cladding System

ULTRA FAST OVERLAY WELDING SpeedClad 2.0

A new dimension in cladding

In comparison with SpeedClad Twin, the new cladding process only requires one electrode and one wire for the same or quicker welding speeds. Considerably fewer wear parts and less maintenance work are clear benefits of this process.

In addition, the much slimmer welding torch allows for the cladding of small interior diameters.

Waste 2 Energy

Membrane walls

Overlay welding to increase the corrosion resistance of membrane walls in power plants and waste incinerators. A special device is used to tension the component and bring it into a vertical position. The trolley, which is guided on a gear rack, moves the two CMT welding heads safely and precisely over the entire weld length. Each welding torch is located on a linear oscillating unit and can be positioned manually using motorized carriages and adjustment units.

Heat exchanger pipes

Overlay welding system with HMI-T10 system controls for mechanized CMT exterior overlay welding of heat exchanger pipes, which are used in power plant construction and waste incinerators. A safety light grid guarantees optimum protection of personnel during the welding process.Customer solutions that are impressively cost effective

Our customers need systems that produce perfect welds throughout the entire product life cycle. They need to be efficient and as profitable as possible. During the engineering phase we therefore place great importance on feasibility studies, simulations and welding tests.