Wear Parts for MIG/MAG Welding Torches

From Contact Tip and Gas Nozzle to Inner Liner

The appropriate wear parts for every welding application

Heat, welding spatter, and continuous abrasion by the welding wire: The forces imposed on wear parts are huge. Extending the service life of wear parts is therefore an extremely important way of lowering production costs and protecting the environment.

Original Fronius wear parts not only extend the service life of your torches, they also reduce potential sources of error and hence produce welding results of the highest quality. Whatever you’re welding – steel, aluminum, CrNi, or CuSi – we offer for every application a comprehensive range of wear parts tailored to your welding process. All Fronius wear parts, including contact tips, gas nozzles, inner liners, and also special shapes, such as small-gap gas nozzles, are developed in Austria. With Fronius, you benefit from a secure supply of wear parts with long service lives!

Advantages of our wear parts

3 types of contact tip with application-specific bore diameters

The material used for the contact tip and the bore diameter both have a decisive impact on the service life of the contact tip. We therefore offer E-Cu, CuCrZr, and WQ contact tips with bore diameters ranging from 0.05 to 0.1 mm.

300 different gas nozzles

We offer a comprehensive range of gas nozzles so can supply the right solution for every welding application. Our range includes small-gap gas nozzles for optimum accessibility, heavy duty gas nozzles for even longer service lives, or coated nozzles for welding aluminum.

6 different types of inner liner

Besides bare steel liners, coated steel liners, CrNi liners, Teflon liners, graphite liners, and bronze liners, we can also provide all these in various combinations. Both the construction and the inner diameter of these inner liners perfectly complement Fronius welding processes.Wear parts at a glance

Among the impressive features of wear parts for steel and CrNi are the insulated gas nozzle and perfect cleaning with a cutter or a strong magnetic pulse. Wear parts for aluminum and CuSi, on the other hand, feature a gas distributor for an optimal protective gas shield and a coated gas nozzle for simple cleaning with a brush.Contact tips for welding torches

The contact tip is the smallest, but the most important, wear part in MIG/MAG welding, and has a major impact on the quality of the welding process.

It transfers the welding current to the wire electrode and, with a constant flow of current, guarantees a stable arc. But which contact tip is best for which welding application?

Special form: Contec contact tip

Ideal for aluminum and CuSi welding.

Features:

- 100% consistent contacting

- Longer service life

- Greater process stability

- Constant tool center point (TCP)

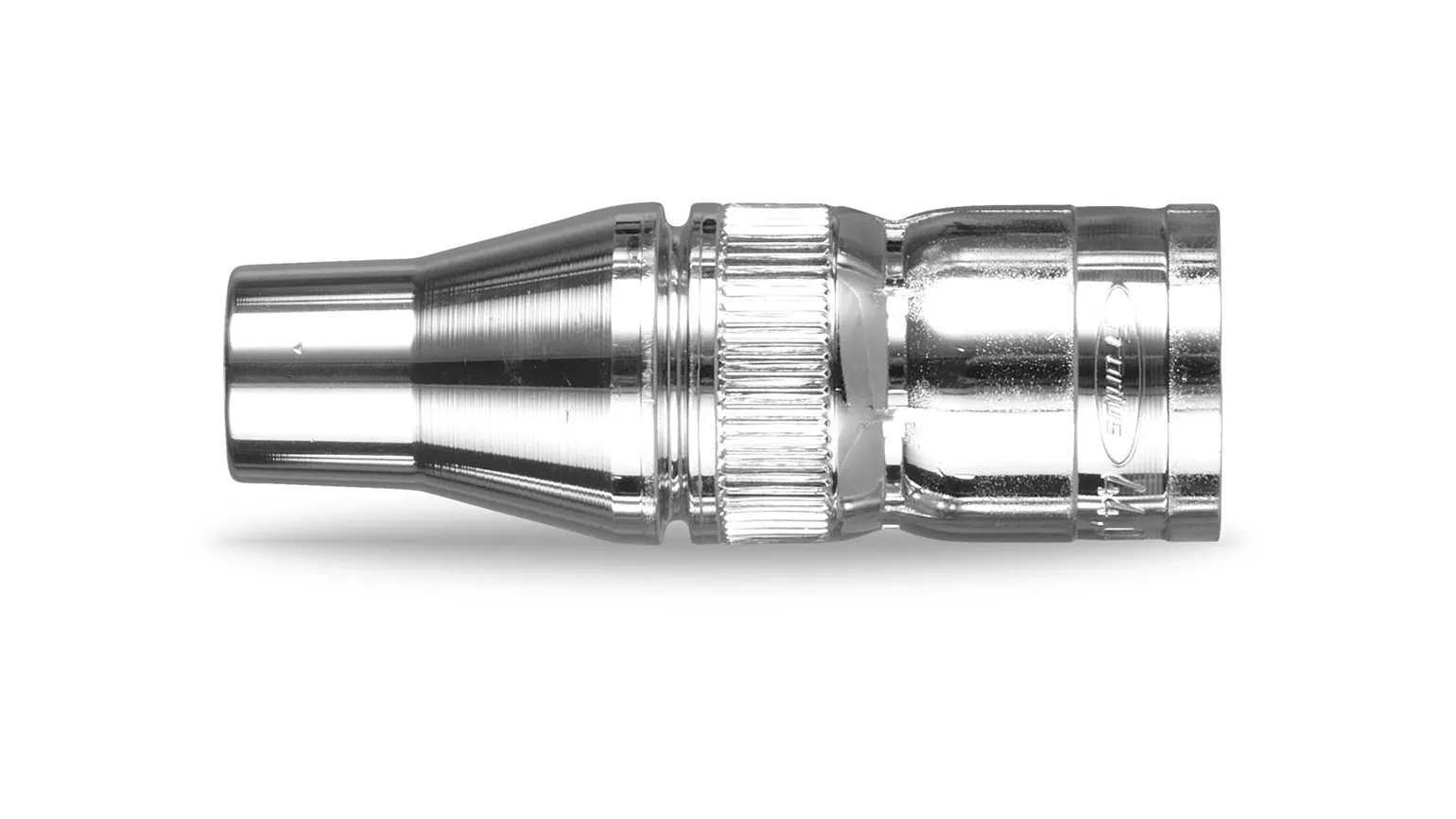

Gas nozzles for welding torches

The gas nozzle ensures a uniform flow of shielding gas into the welding process. This constant flow of gas protects the arc and the weld pool from the atmosphere. We have the right gas nozzle for every welding application.

Gas nozzles that have been specially developed for aluminum applications ensure that spatter rarely sticks, consequently reducing the turnover in wear parts.

Special form: Small-gap gas nozzle

Feature:

- Narrow gas nozzle for optimal accessibility

Inner liners for welding torches

The task of the inner liner is to feed the welding wire smoothly from the wirefeeder to the contact tip.

We provide the appropriate inner liners – and combinations of them – for every application area. Our range includes bare steel liners, coated steel liners, CrNi liners, Teflon liners, graphite liners, and bronze liners. Both the construction and the inner diameter of these inner liners perfectly complement Fronius welding processes.

Gas distributors for welding torches

The gas distributor is mainly used for aluminum welding and produces a uniform flow of shielding gas.

The materials used in our gas distributors impress with their long service lives.