Welding with the iWave

The intelligent TIG welding system

The Fronius TIG welding system that makes no compromises

Precise. Durable. Intuitive. With the iWave series, not only can you smash everyday welding tasks; you can also unleash your welding potential and make yourself future-proof. Flexible.

Top quality – for every weld and every material: with its targeted heat input and improved ignition function, iWave gives you maximum control over your arc while significantly reducing ignition delays.

All the operating controls on the iWave series have likewise been designed for maximum control. This makes the systems intuitive to use, leaving you free to concentrate solely on the challenges of your welding task.

Need a system that can master the full array of welding challenges? If so, iWave Multiprocess PRO is the perfect choice: in addition to offering every imaginable TIG function, it also accommodates all MIG/MAG welding process variants.

iWave: Complete freedom to unleash your welding potential.

iWave highlights

Targeted heat input

Maximum control over the weld pool

CycleTIG allows you to control the arc, in turn giving you maximum control over heat input. The short welding times make it easy to keep a safe handle on the weld pool. As a result, you can weld even the thinnest of materials with ease.

Intuitive operation

Dynamic graphics-based menu navigation – in over 30 languages

No additional documentation. No wild goose chases. Just follow your instincts. Our intuitive menu navigation concept eliminates unnecessary detours during welding, allowing you to make the required settings with confidence.

Multiprocess PRO

One system for all processes (iWave 300i–500i)

iWave and Multiprocess PRO – your key to unbridled welding freedom. Along with every possible TIG function, all MIG/MAG welding process variants are accommodated within a single system. Benefit from the modular concept that allows you to expand your high-tech welding system platform according to your exact needs. Simply choose from the following Welding Packages: Standard, Pulse, PMC, or LSC and CMT.

Reproducible ignition processes

Ignition delays reduced by up to 71%*

Ignition processes that are fast and – perhaps even more importantly – reproducible. Regardless of the material characteristics and without having to adjust any ignition parameters manually. That’s what you get when you opt for RPI auto – our intelligent ignition function.

* Compared to RPI off | Test series conducted under laboratory conditions: 200 A welding current / 0.5 s welding time / 1,000 ignitions!

Industry 4.0 ready

Contactless data transfer and authentication

Ready for Industry 4.0 and anything else that comes its way: from WLAN and Bluetooth right through to NFC, iWave supports all the major connection standards so that you can put it to the best possible use.

The iWave welding system variants at a glance

| iWave 190i AC/DC | iWave 230i DC or iWave 230i AC/DC |

iWave 300i DC or iWave 300i AC/DC |

iWave 400i DC or iWave 400i AC/DC |

iWave 500i DC or iWave 500i AC/DC |

| 3-190 A (TIG) | 3-230 A (TIG) | 3-300 A (TIG) | 3-400 A (TIG) | 3-500 A (TIG) |

| 230 V single-phase or 120-230 V single-phase (MV) |

230 V single-phase or 120-230 V single-phase (MV) |

400 V three-phase or 200-600 V three-phase (MV) |

400 V three-phase or 200-600 V three-phase (MV) |

400 V three-phase or 200-600 V three-phase (MV) |

| Gas-cooled | Gas-cooled or water-cooled | Gas-cooled or water-cooled | Gas-cooled or water-cooled | Gas-cooled or water-cooled |

| TIG, MMA | TIG, MMA | TIG, MMA, and MIG/MAG (all WPs) |

TIG, MMA, and MIG/MAG (all WPs) |

TIG, MMA, and MIG/MAG (all WPs) |

| Connectivity (WLAN, Bluetooth, NFC) as std. |

Connectivity (WLAN, |

Connectivity (WLAN, Bluetooth, NFC) as std. |

Connectivity (WLAN, Bluetooth, NFC) as std. |

Connectivity (WLAN, Bluetooth, NFC) as std. |

| Ethernet optional | Ethernet optional | Ethernet and SpeedNet as standard |

Ethernet and SpeedNet as standard |

Ethernet and SpeedNet as standard |

TIG

iWave 190i-500i

The intelligent TIG welding system for industrial applications and outstanding quality whatever the materials involved.

- iWave DC:230i/300i/400i/500i

- iWave AC/DC: 190i/230i/300i/400i/500i

Multiprocess PRO

iWave 300i-500i

One welding system for all welding processes (TIG – incl. HF – and MIG/MAG right through to WP CMT, MMA, and CEL) with no compromises on quality.

- iWave DC: 300i/400i/500i

- iWave AC/DC: 300i/400i/500i

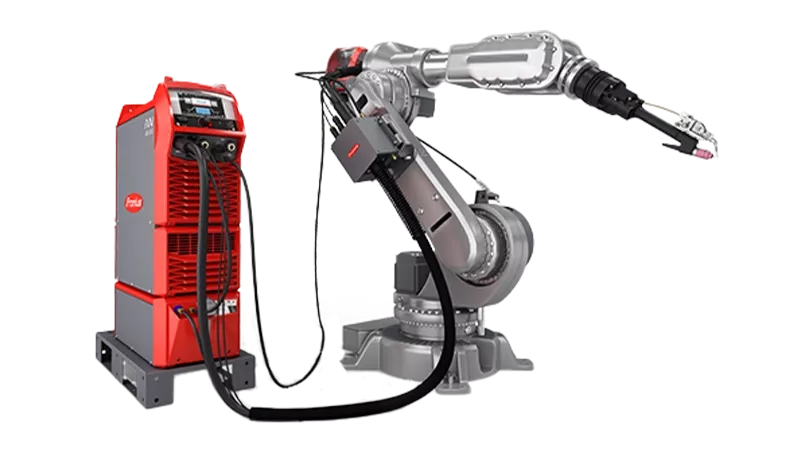

iWave

The all-rounder in automated welding

New technologies and innovations such as DynamicWire and CycleTIG or the unlimited Multiprocess capability of iWave also offer numerous advantages and new possibilities for automated welding applications.

Welding with the multiprocess welding system iWave

Challenge:

The renowned Austrian contract manufacturer joins metal components for national and international clients. Component accessibility, material and design require that components be welded with both MIG/MAG and TIG. The space requirement for two different welding systems and the constant change between the two turned out to be an inefficient approach for Ferrum.at. A powerful and reliable all in one solution was therefore needed for the future.

Solution:

iWave AC/DC 400i

Process

Application:

WIG (Cycle TIG)

MIG/MAG (PMC)

Improved control

A safe bet for improved results

Made by welders for welders: all the operating controls on the iWave series have been designed with your daily tasks in mind – in terms of their sturdiness, colors, legibility, and brightness. That also goes for the settings, as all the key work parameters are directly available on the very first menu level. The plain text display supports over 30 languages for maximum intelligibility. Not only that, but operation while wearing gloves has never been easier.

iWave 300i-500i

Plain text display in over 30 languages gets you to the relevant setting as quickly as possible

Intuitive and reliable: the system is operated using the central press-and-turn button or via the touchscreen. Users receive direct support in the form of graphic-based instructions and dynamic visualizations when making changes to parameters.

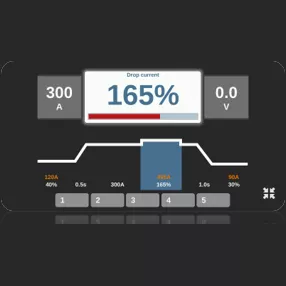

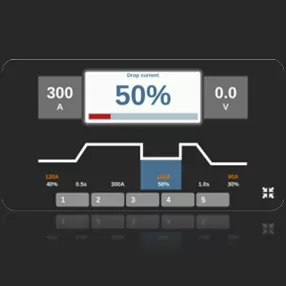

Dynamic graphics-based operating concept

- Immediate graphic feedback whenever various welding parameters are changed

- 7" color plain-text display and touchscreen

- More than 30 language options

- All work parameters located on 1st menu level

- Status display: configured additional functions and main settings at a glance

- 5 EasyJobs

- Touchscreen can even be operated while wearing gloves

- Full-screen mode: increases display size by around 40%

- Configurable 1st menu level

Straightforward. Clear. Structured.

The iWave operating controls

iWave 190i-230i

Easy and intuitive operation

- Immediate graphic feedback whenever various welding parameters are changed

- 4.3" color plain-text display

- More than 30 language options

- All work parameters located on 1st menu level

- Easy to operate while wearing gloves

- Status display: configured additional functions and main settings at a single glance

- 5 EasyJobs and 3 user-defined parameters on 1st menu level

- Configurable favorites button

User management

Individual authorizations for different users

Complete control: the integrated authorization system allows you to assign individual permissions to each user. When someone logs in with a key card or fob, the system immediately knows what they are – and are not – allowed to do. And if you want the perfect solution for assigning and administering authorizations for multiple welding systems centrally, you need look no further than our Central User Management.

Easy administration on the welding system

Create new users in just five steps: create and define role, create and define user, assign card, AND YOU’RE DONE.

Easy locking and unlocking

The welding system can be unlocked really easily with a card or key fob. You also have the option of using a dedicated NFC card.

Manage individual authorizations for each welding system

This means people can only perform actions on the system for which they have been specifically authorized.

PC-based user management

Efficiency savings of more than 90% (measured in clicks) when setting up an account for someone who needs access to 20 systems. * Compared to creating the account directly on the welding system display

Central User Management

A clear reduction in complexity: only one tool required to manage different systems.

Industry 4.0 ready

Full connectivity: contactless data transfer and authentication

Industry 4.0 performance levels: iWave supports all the main communication standards. Wirelessly connect peripheral devices to the welding system in next to no time – that means anything from high-tech welding helmets (such as the Vizor Connect) to remote controls. Use WLAN to integrate welding systems directly into your network for easy firmware updates.

NFC

For user management – or for locking and unlocking the welding system with ease.

WLAN

For complete network capability – to enable updates and use of the Smart Manager function without an Ethernet connection (data documentation).

Bluetooth

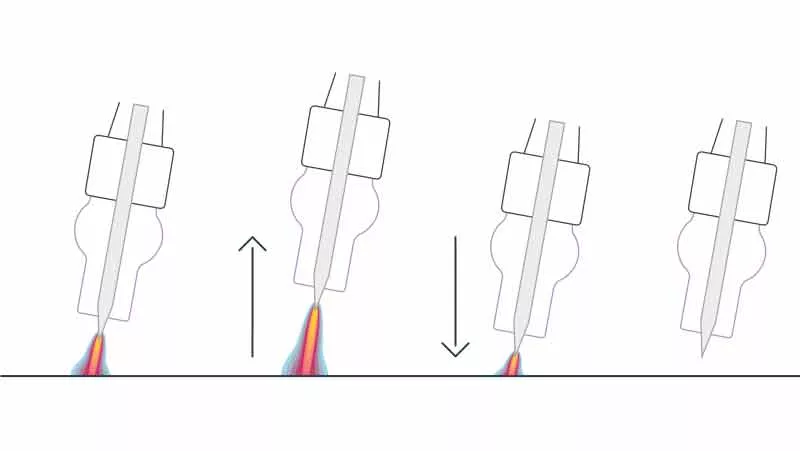

For connecting wireless remote controls and Bluetooth-enabled welding helmets.CycleTIG

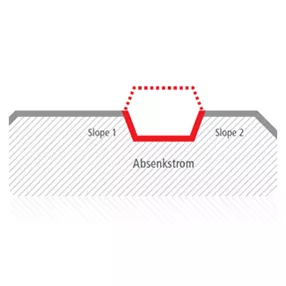

For targeted heat input

TIG welding made easy: all thanks to the CycleTIG function. Based on the principle of stitch welding, this function offers additional setting options and new parameter combinations for improved welding results.

- Excellent weld appearance

Achieved with the TACKING function - Targeted heat input

Ideal for welding light gage sheets and for edge hardfacing welds - Easy control of the weld pool

No burn-through – even in the case of corner and butt welds - Reduction in temper colors

For sensitive usage locations - Easy handling

For clean welds

TIG ignition

Stable and reproducible

Noticeably better: iWave takes TIG welding ignition behavior to a whole new level. We have optimized the HF ignition process and adapted the ignition behavior to suit the various electrode diameters.

RPI AUTO* – ignition delays reduced by up to 71%**

Are you looking for a faster ignition process that is fully reproducible – regardless of the material characteristics involved? If so, iWave offers an off-the-shelf solution in the form of RPI auto. The new ignition mode is the next logical step in the development of the proven “RPI on” function. The welding system now makes changes to the ignition settings automatically – including when it is necessary to counter deteriorations in ignition and without any need for manual intervention.

* Only available on iWave AC/DC

** Compared to RPI off | Test series conducted under laboratory conditions: 200 A welding current / 0.5 s welding time / 1,000 ignitions!

| How they measure up | RPI off | RPI on | RPI auto |

| Reproducible ignition processes | •• | ••• | •••• |

| Minimal ignition delay | ••• | • | •••• |

| Minimal electrode load | ••• | • | •• |

| Gentle action on the weld surface |

•••• | •• | ••• |

Further iWave functions

Arc ignition

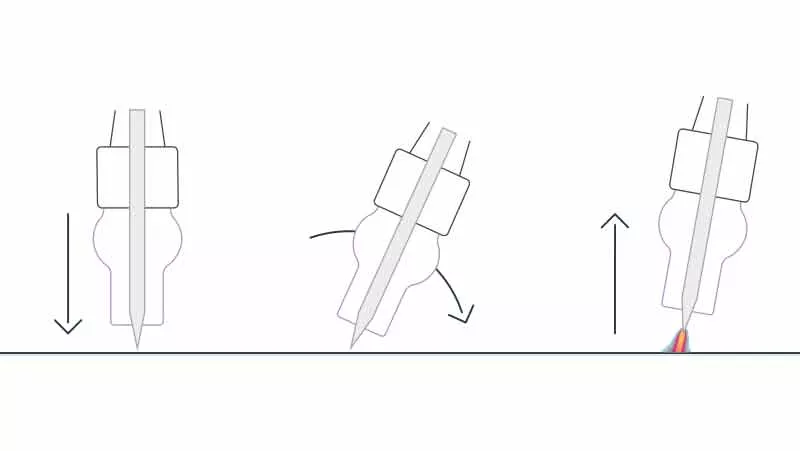

1. SoftStart

Contact ignition – by touching the workpiece with the electrode.

2. High frequency (HF)

Touchless ignition via high-voltage pulses when the torch trigger is actuated.

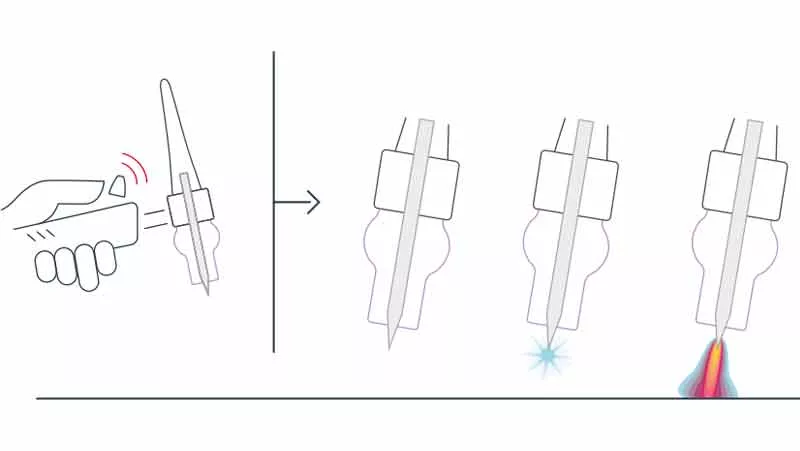

3. Touch HF

A special form of high-frequency ignition – ignition only takes place once the workpiece and electrode make contact. This enables ignition at a precise point without any risk of tungsten inclusions.

Stopping the welding process

1. TIG Comfort Stop

Stops the welding process without a torch trigger – by briefly lifting and lowering the electrode.

2. Arc break voltage

Definable arc break voltage – for stopping the welding process. The arc is switched off as soon as the set voltage is reached.

Tacking

Quick and easy tacking

Time savings of up to 50% when tacking materials

The TACKING function causes the weld pool to oscillate briefly at the beginning. As a result, you can tack your components together in a single step because the material of both edges merges beautifully – without burning the edges. Very little to no temper coloration occurs at the tacking points. What’s more, no filler metal is required – even with small air gaps of up to 1.5 mm.

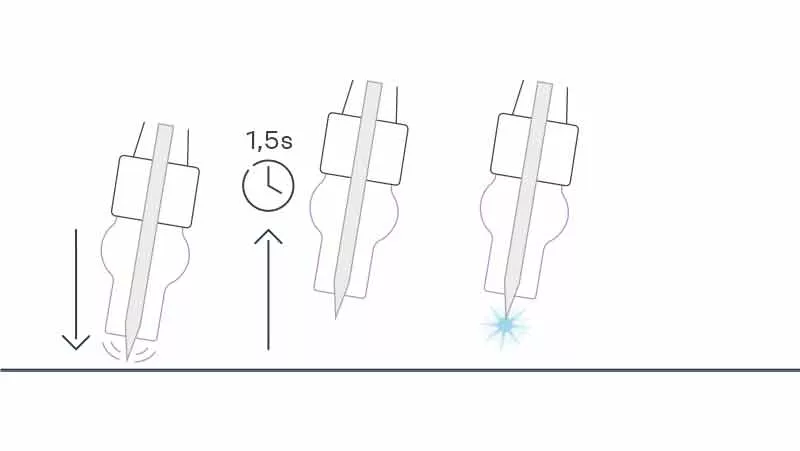

Automatic cap-shaping

In just 2 seconds

This function* allows a cap to be formed very quickly based on the set electrode diameter. In this way, you can save yourself a ton of work time.

Example: Electrodes with Ø 1.6 mm

| Time required (without function): |

91 seconds |

| Time required (with function): |

2 seconds |

| Savings: |

~ 1.5 minutes |

| 8 times per day |

~ 12 minutes |

| 5 days/week | ~ 1 hour |

| 40 weeks/year |

~ 40 hours |

Savings: One working week per year and per welder.

The right arc for every application

Weld however you like: for AC welding, iWave allows you to select the waveforms yourself. In other words, the ones that characteristically produce your preferred weld properties for the welding task at hand. If necessary, you can also combine different waveforms.

Waveforms:

Pulses

Standard range of functions

- Pulse current setting

- Pulse frequency setting

- Pulse frequency up to 2 kHz

Extended range of functions with OPT/i Pulse Pro

- Base current setting

- Duty cycle setting

- Pulse frequency up to 10 kHz

- DC waveforms

Tungsten electrode protection

Automatic gas post-flow

Ensures that the tungsten electrode and weld are protected by a gas shield, thereby preventing oxidation. The gas post-flow time is calculated on the basis of the set welding current and electrode diameter.

Warning in the event of electrode overload

- Monitoring and notification with DC and AC/DC

- AC current offset and balance also taken into account

Synchronized welding

Both arcs automatically harmonized in a reliable way thanks to “Sync Mode”

Smashing the challenge: our “Sync Mode” makes simultaneous two-sided TIG welding with alternating current easier than ever before. This is the ultimate welding challenge, which we have overcome by automatically harmonizing both arcs. As a result, two welders can work together in perfect synchronism.

WeldCube Light

Minimal local documentation

Record mean values for every weld directly in the welding system and export them in PDF format – as standard and at no additional cost.

WeldCube Basic

Enhanced local data documentation with a configurable range of functions

The solution for anyone who needs more than just mean values and wants to get their hands on actual values, limit monitoring, and editing functions for set values: WeldCube Basic. Like the other versions, this one also records data directly in the welding system.

WeldCube Premium

Central data documentation

The ability to store your welding data centrally in a database significantly reduces the amount of time and effort required for documentation and administration. The intelligent management, statistics, and analysis functions – including graphic visualization – provide you with a fantastic overview of your welding production activities.

WeldCube Navigator

Real-time feedback solution for welding specialists

High-quality welds are essential for many products. Faulty or missed welded joints lead to high manufacturing costs. The earlier these faults are identified in the manufacturing process, the quicker it is to respond to them.

WeldCube Air

The future of digital data management

WeldCube Air is a secure, cloud-based platform allowing you to conveniently connect to and visualize welding data. There are no complicated procedures involved in installing the application. It’s ready to use right away, and facilitates the efficient management of your welding operations.

Welding Package: TIG Dynamic Wire

Active wire control in TIG cold wire welding:

The innovative advantage of Fronius TIG DynamicWire, when compared to a conventional continuous wire feed in cold wire systems, lies in its automatic self-regulation.

The power source actively adjusts the wire speed to the welding behavior, torch position, and current conditions, even compensating automatically for component tolerances of up to 30%.