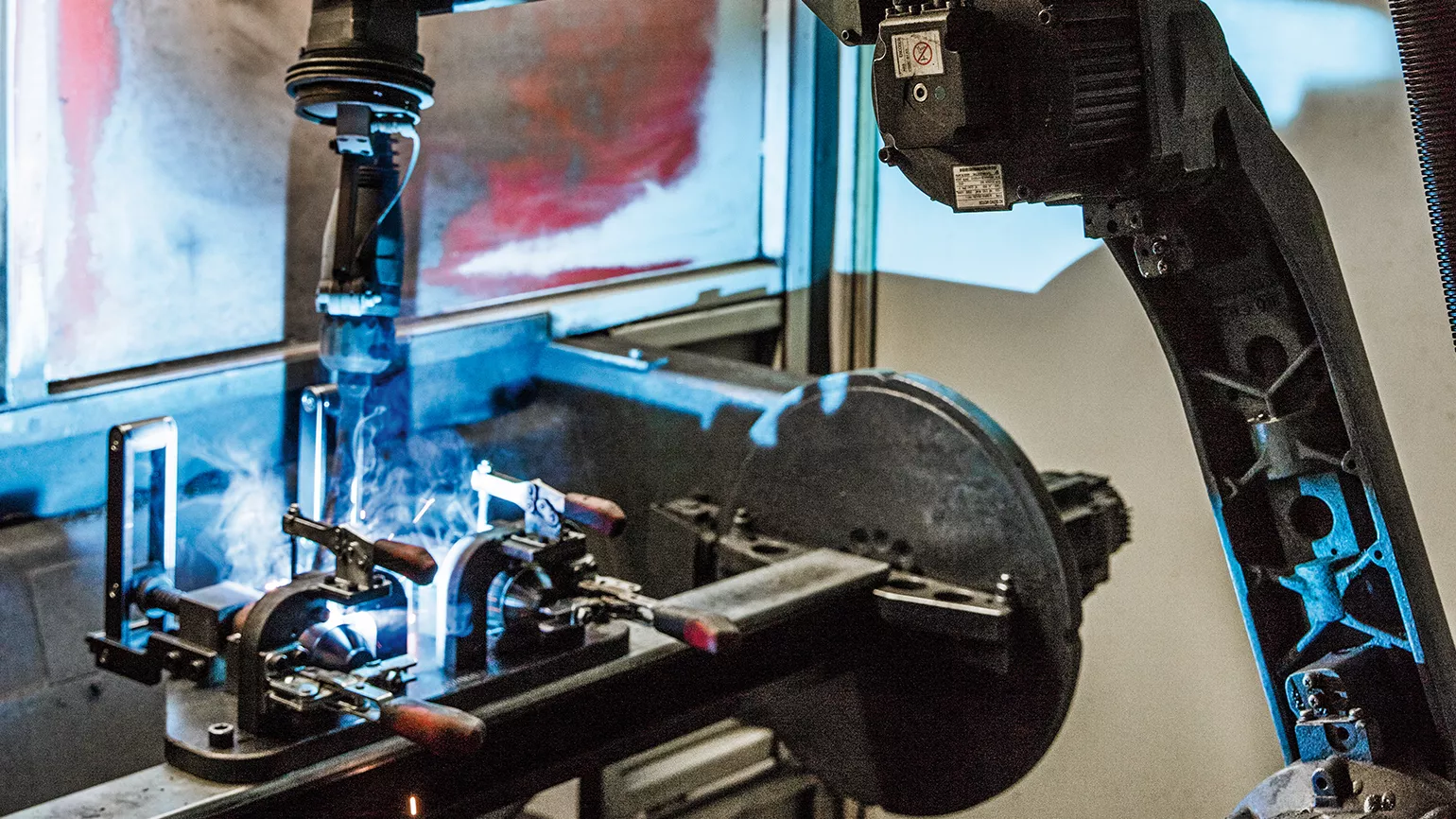

Robotic Welding in the Automotive Industry

10% Weight Reduction.

For 15,3 Grams less CO2.

Challenge

Modern vehicles needs to meet increasingly strict exhaust emission regulations, but at the same time customers expect more and more safety and comfort features. The automotive and supplier industry therefore relies on lightweight concepts, and light metals such as aluminum and magnesium, as well as high-strength and super-high-strength steels, are becoming increasingly important as materials.

This also means that welding technology is facing new challenges, and requires innovative solutions. Cost effectiveness is also crucial in the automotive industry, and in order to keep up with international competition, manufacturers and suppliers need to make their production processes as efficient as possible in terms of time and costs.

Partner in the Automotive Industry

Quality

- First class products according to the highest industry standards

- Outstanding service from highly trained specialists

- Worldwide support directly on the customer’s premises

Cost effectiveness

- Technology and innovation leader in welding technology

- Professional training for your employees

- Comprehensive knowledge of the automotive and supplier industry

Know-how

- Time and cost optimized production processes

- Seamless integration into the production process

- Constant new development and further development of efficient welding processes

Good relationships

- 25 years of experience in the automotive industry

- Long-term partnerships and reliable cooperation with customers around the world

Questions on welding solutions for the automotive industry?

Submit your non-binding inquiry directly to Fronius.

Our team will gladly provide you further information.

Production Monitoring with WeldCube.

One piece of software - all power sources at a glance.

Process and cost optimization are of central importance for the automotive and supplier industry, and the documentation of production data is an important key to achieving this. With WeldCube from Fronius, you can continuously record and analyze the welding data of all power sources on all production lines.

The result: greater transparency, safety and verifiable weld quality for your series production.

Save time and money with WeldCube:

- Access welding data of up to 50 power sources centrally irrespective of the device, and analyze data at the touch of a button

- Create and manage jobs centrally and distribute to the power sources

- Optimize costs with simple analysis of consumption of gas and filler metals

- Call up data quickly when servicing is needed, and therefore reduce downtimes

- Continuous data documentation for quality assurance and to comply with standards

Read more about the subject

How data analysis improves the world of welding!

Fronius has developed the WeldCube documentation and data analysis system. As a result, welding processes can be optimized and errors avoided.

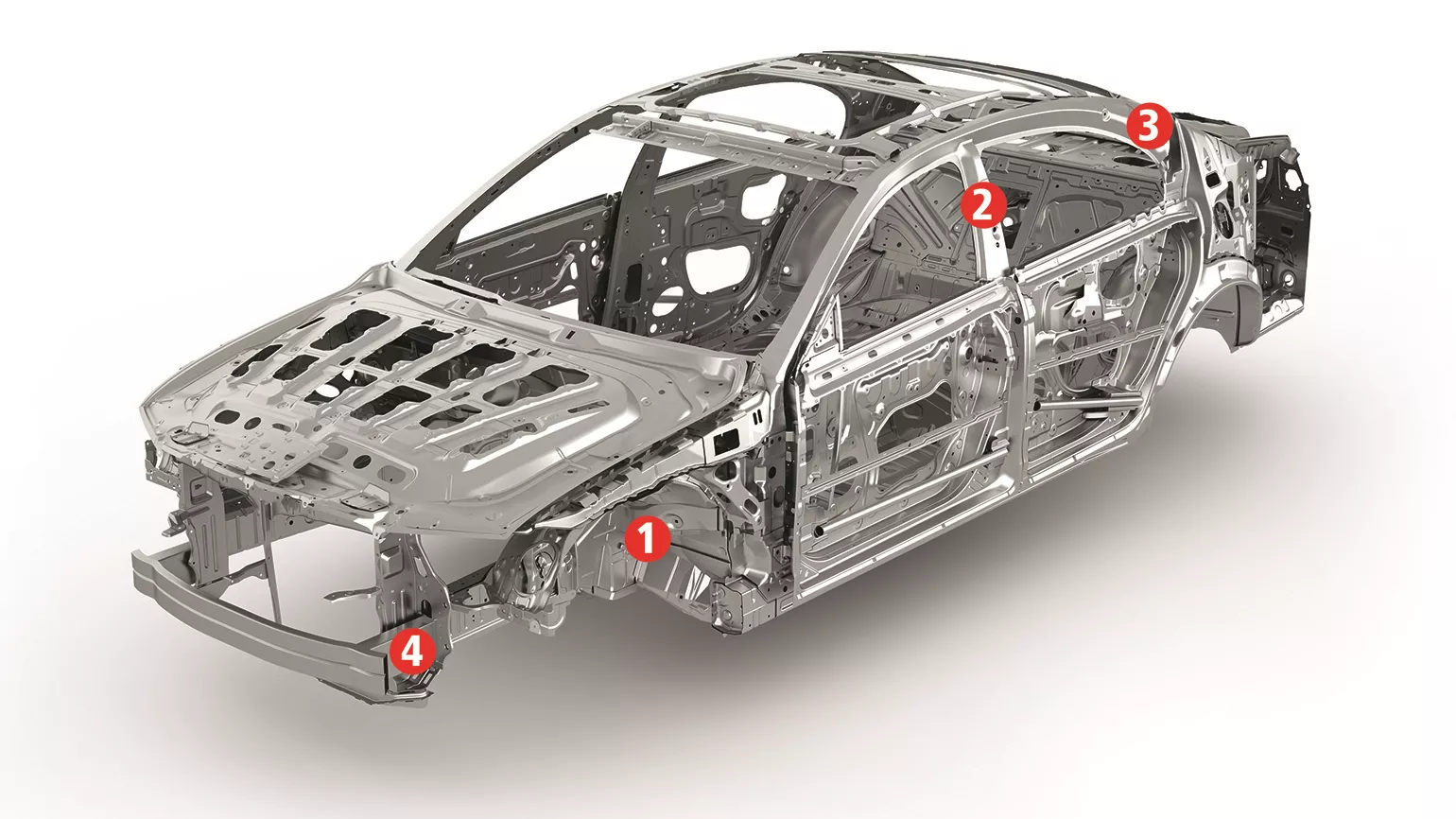

Body in White

Whether steel, aluminium or mixed applications.

Fronius offers the optimum welding process.

Challenge

- Practically spatter-free welding and brazing on galvanised steel

- Low distortion due to optimised heat input

- Low porosity

- Stable arc

- Optimum penetration

- High welding speeds

Solution

TPS/i PMC/CMT

LaserHybrid

Challenge

- Practically spatter-free welding of hot pressed components

- Lower heat input (up to -50%) than with conventional gas metal arc welding

Solution

TPS/i PMC/CMT

LaserHybrid

Challenge

- Fast brazing (up to 3 m/min)

- Lower heat input

- Flat and clean weld seam

- Best weld seam appearance

- Up to 60% less shielding gas

- Spatter-free

Solution

TPS/i PMC/CMT

LaserHybrid

Challenge

- High stability of the arc

- Lowest heat input

- Steel-aluminium joints possible

- Minimal spattering

- High gap-bridging ability

Solution

TPS/i PMC/CMT

LaserHybrid

Welding Challenges

- High welding speeds

- Joining different materials (Steel-aluminium joints possible)

- Flat and clean weld seam

- Lowest heat input and low distortion

- Spatter-free welding

Exhaust gas systems

Material: ferritic chrome steel

Challenge

- High component tolerance

- High welding speed

Solution

TPS/i PMC / LSC

Material: steel

Challenge

- No spatter

- Stable arc

- High Welding Speed

Solution

TPS/i CMT

Material: ferritic chrome steel

Challenge

- No spatter

- Stable arc

- High welding speed

Solution

TPS/i CMT

Material: ferritic chrome steel

Challenge

- Good penetration

- Good gap-bridging ability

- High welding speed

Solution

TPS/i CMT

Welding challenges

- Welding very thin materials

- Joining materials of different thicknesses (flange)

- Multiple sheet joints

- High component tolerances

- Damage to sensitive parts such as catalytic converters or particle filters by welding spatter

- Cost effectiveness in production, large quantities

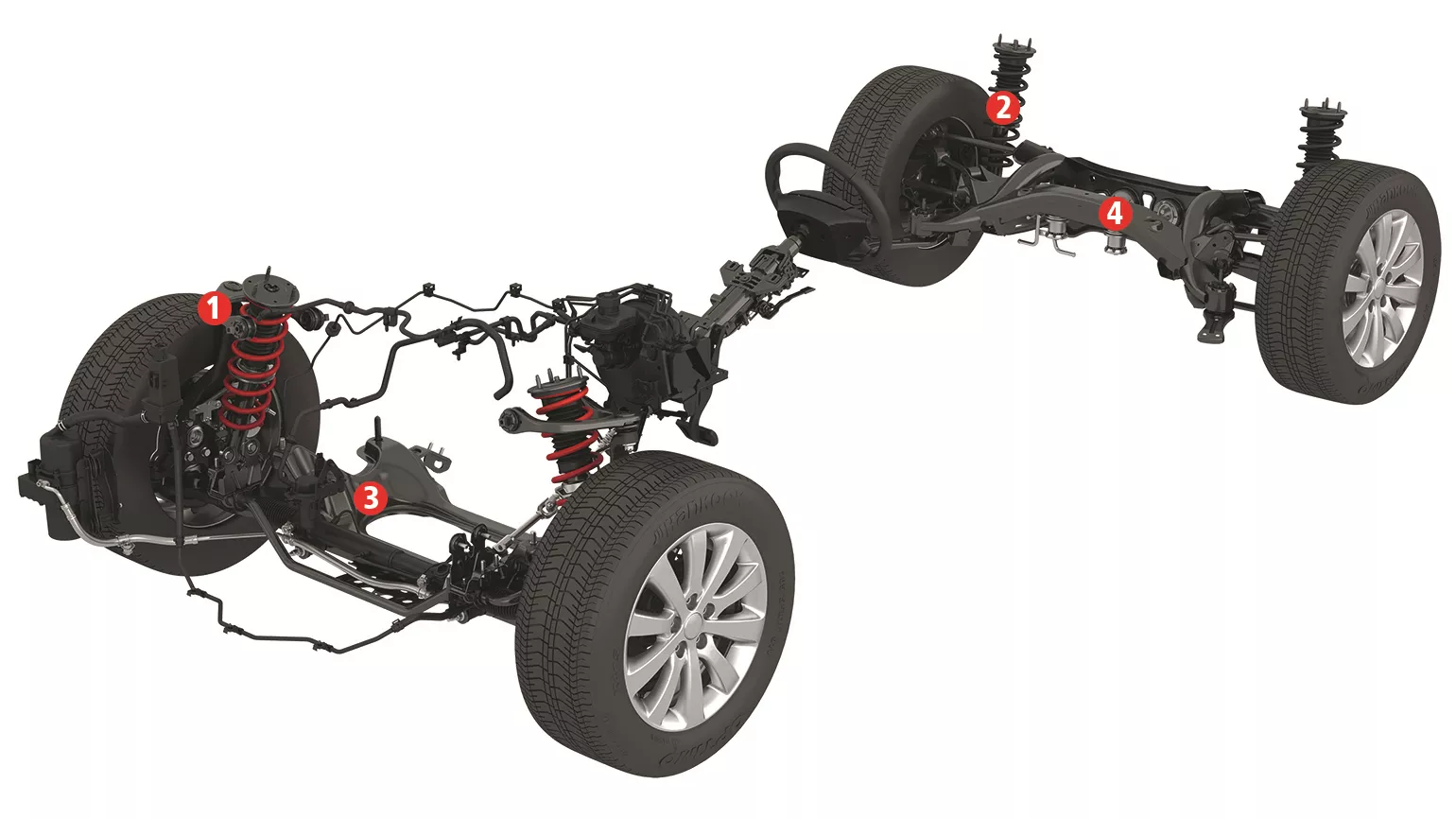

Chassis

Material: steel

Challenge

- High welding speed

- Continuous root formation

Solution

TPS/i PMC

Material: steel

Challenge

- Good penetration

- Less spatter

- High welding speed

Solution

TPS/i PMC

Material: aluminium

Challenge

- High welding speed

- Low heat input

- Good gap-bridging ability

Solution

LaserHybrid

Material: steel

Challenge

- High component tolerances

- High welding speed

- Less spatter

Solution

TPS/I PMC

Welding Challenges

- Reduced porosity and quality welds

- High travel speeds for improved cycle time

- Gap bridging ability at high travel speeds

- Reduced distortion

Interior (seats, cross car beam)

Material: steel

Challenge

- Low heat input

- Less spatter

- Thick/thin joints

Solution

TPS/i CMT

Material: steel

Challenge

- Short weld seams

- Stable ignition

- Good penetration

Solution

TPS/i PMC

Material: steel

Challenge

- No spatter

- Stable arc

- Short weld seams

- Low heat input

Solution

TPS/i CMT

Welding challenges

- Very thin materials

- Mechanisms sensitive to spatter

- High-strength and super-high-strength steels

- Very short weld seams

- Consistent quality

- Different material thicknesses

- Cost effectiveness in production

Benefit from Our Services

Increase productivity and performance

We support you in the startup phase of your production process by providing production monitoring. Due to tailor-made and quick integration of our products, you benefit from optimized cycle times, avoid reworking and the system will be easy to use.

Expert know-how for your employees

To ensure that production is top quality in all countries, it is essential that all employees have the same level of knowledge, which is achieved through instruction, seminars and training.

Make optimum use of resources

With our years of experience in the automotive industry, we help you to optimize your production processes and parameter settings.

Reduction in downtime

We take over the servicing and maintenance of your welding systems for you and help you to avoid downtimes and save personnel costs as a result.