Innovative resistance spot welding of aluminium: from the test bench to the production line

Georg Fischer Automotive AG, Austria

Georg Fischer Automotive AG counts among the world’s leading suppliers of iron and light metal casting parts for commercial vehicle and car drives, chassis and bodies. With a total of 12 production sites and approximately 5,500 employees around the world, GF Automotive is a global partner and supplier to the automotive industry. Its plant in Austria specialises in manufacturing structural parts, including strut brackets and doors, for example for the Porsche Panamera.

Downloads

Alois Edtbauer, Specialist Buyer for Georg Fischer

“The DeltaSpot process from Fronius proved to be extremely reliable and efficient for processing the Porsche Panamera door frames.”WELDING CHALLENGE

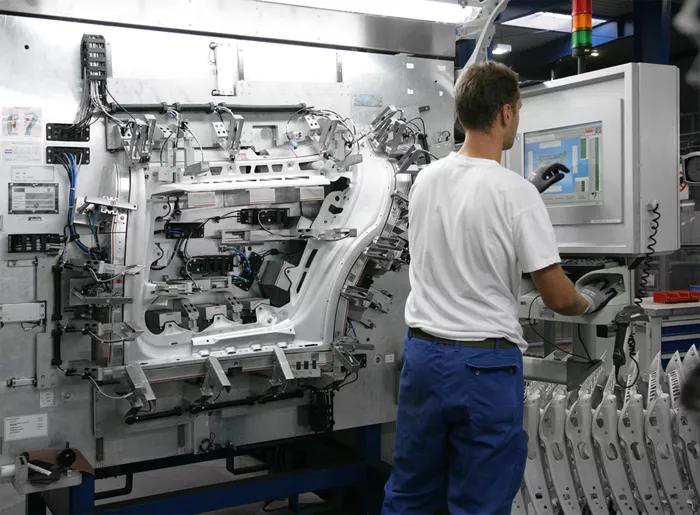

Welding joints on the Porsche Panamera’s three-millimetre-thick door frames demands an extremely high level of dimensional accuracy. The process must also be as spatter-free as possible in order to protect the primary seal between the door and the frame at the point that has to be joined. In addition, the thermally induced distortion on the workpiece has to be kept within tight limits to allow for mechanical rework. Conventional resistance spot welding processes were ruled out for production- and process-engineering reasons.

“Thanks to DeltaSpot we can offer an alternative production step, which gives us a significant competitive edge.” Wolfgang Hintsteiner, engineer at Georg Fischer

SOLUTION

The special DeltaSpot resistance spot welding system from Fronius is the ideal solution for the challenging process of joining aluminium frames. It has proved its merits on the production line at GF since 2008. Using the DeltaSpot process tape, a uniform, exactly replicable spot is produced on every workpiece. This enables a consistent cycle to be achieved – each Panamera door is welded in approximately 100 seconds. As a result of the clean welding spots the surface does not require any mechanical rework, which saves time and increases reproducible process quality.