Yellow Goods Welding Solutions

Highest quality requirements

double productivity

Challenge

Long weld seams, several weld layers and a high deposition rate - at a high welding speeds

Joining heavy components in the Yellow Goods industry represents a particular challenge. Huge components and extremely thick materials are an everyday occurrence – take, for example, a one-and-a-half-meter long heavyduty axle made from steel up to 50 millimeters thick.

The weld seams must withstand high forces and meet stringent quality criteria. The weld seam appearance also plays an important role. Compared to other welding sectors, greater component tolerances and gap-bridging ability are required in the Yellow Goods sector.

Strong partnership for heavy-duty components

A wide range of components of all shapes, sizes, and weight classes require customized welding solutions. The close partnership with Fronius means that an efficient and reliable supply of just such solutions is guaranteed. We are there whenever you need us – quickly, competently, worldwide.

Quality

- High-quality products that meet every industry standard

- Outstanding service thanks to highly skilled experts

- Global support at a local level

Cost-effectiveness

- Tailored integration of our products in the respective manufacturing process

- Production costs and cycle times for further developments are always in mind

- Immediate availability of replacement devices and spare parts in the event of downtime

Know-how

- Latest developments from the welding sector

- Professional training for your employees

- Comprehensive knowledge of production processes in the Yellow Goods industry

Good relationships

- Long-standing partnerships and reliable collaboration with customers

- Reliable contact partner and provision of intensive support for all welding matters

Questions on welding solutions for the yellow goods industry?

Submit your non-binding inquiry directly to Fronius.

Our team will gladly provide you further information.

Excavator

Overlay welding

Challenges

- High deposition rate

- Robust equipment

Solution

TPS 600i single wire

- Welding speed: 60 cm/min

- Deposition rate: 8 kg/h

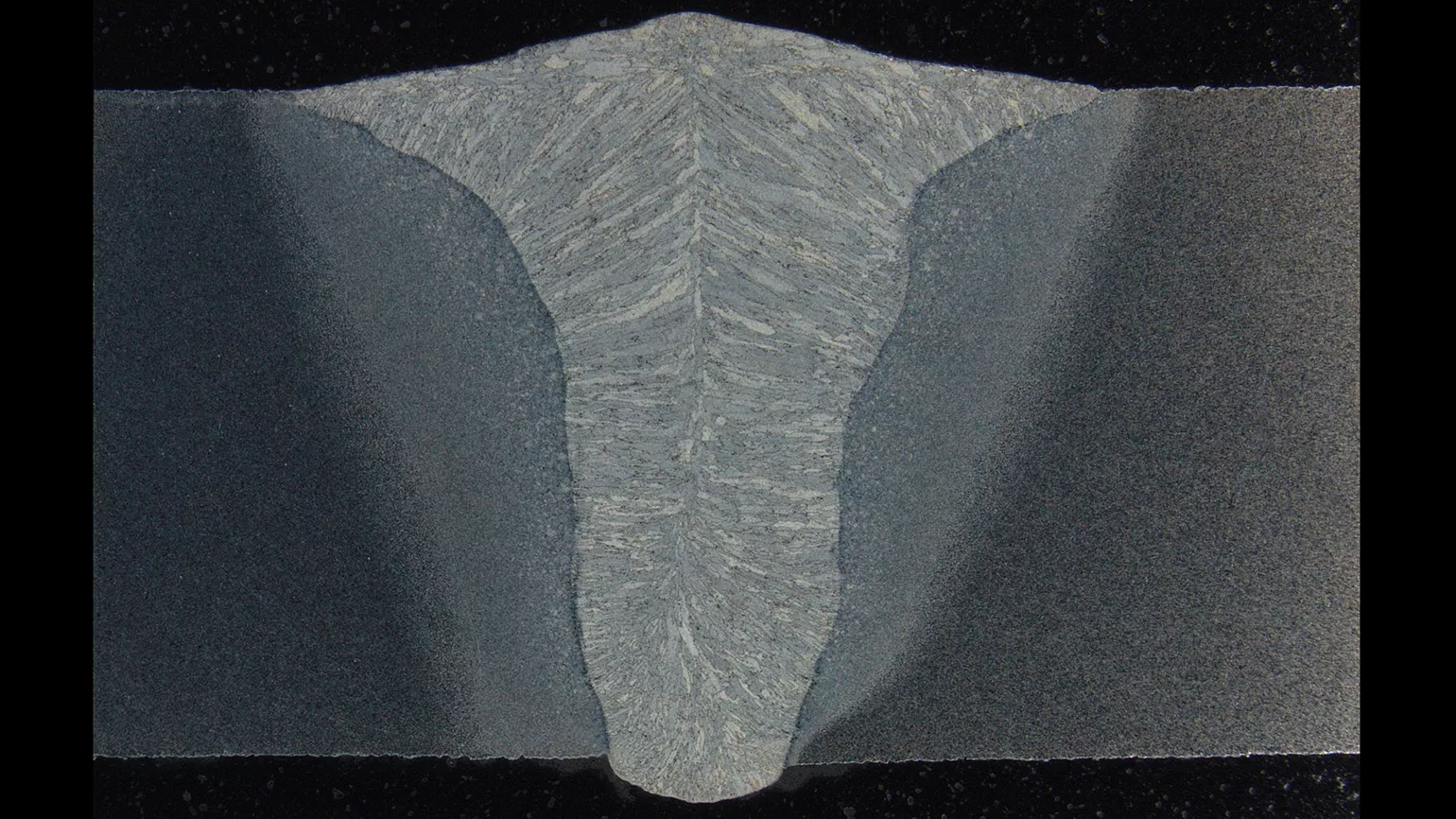

Circumferential weld

Challenges

- Deep penetration

- Low heat input

- Little welding spatter

Solution

TPS TWIN CMT

- Material thickness: 10 mm

- Welding speed: 60 cm/min

- Deposition rate: 12 kg/h

Fillet weld

Challenges

- High deposition rate

- Welding speed

- Low-spatter

Solution

TPS 600i single wire

- Material thickness: 10 mm

- Welding speed: 25 cm/min

- Deposition rate: 11 kg/h

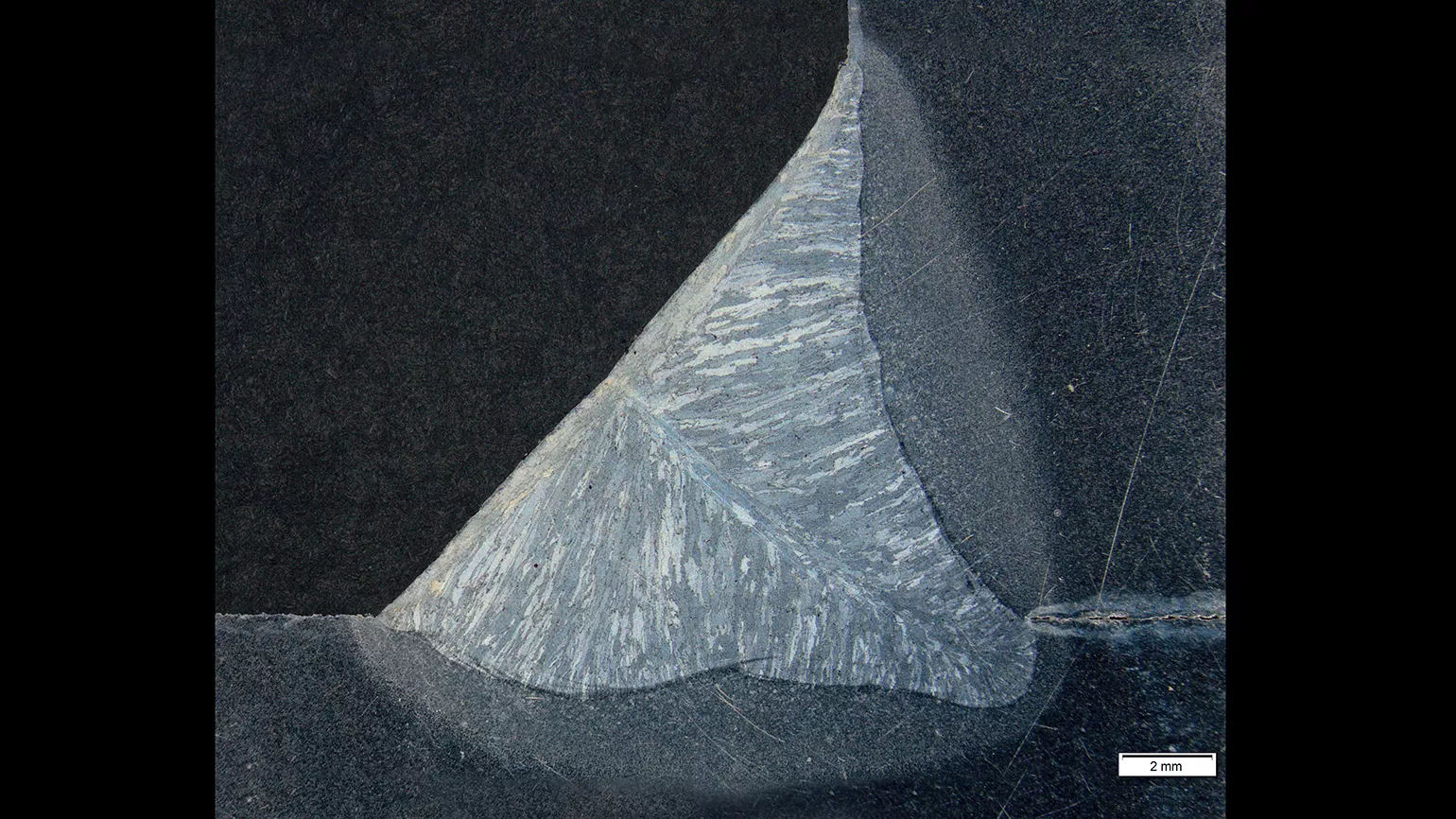

Fillet weld

Challenges

- Deposition rate

- Welding speed

- Gap-bridging ability

Solution

TPS/i TWIN Push

- Material thickness: 15 mm

- Welding speed: 60 cm/min

- Deposition rate: 18 kg/h

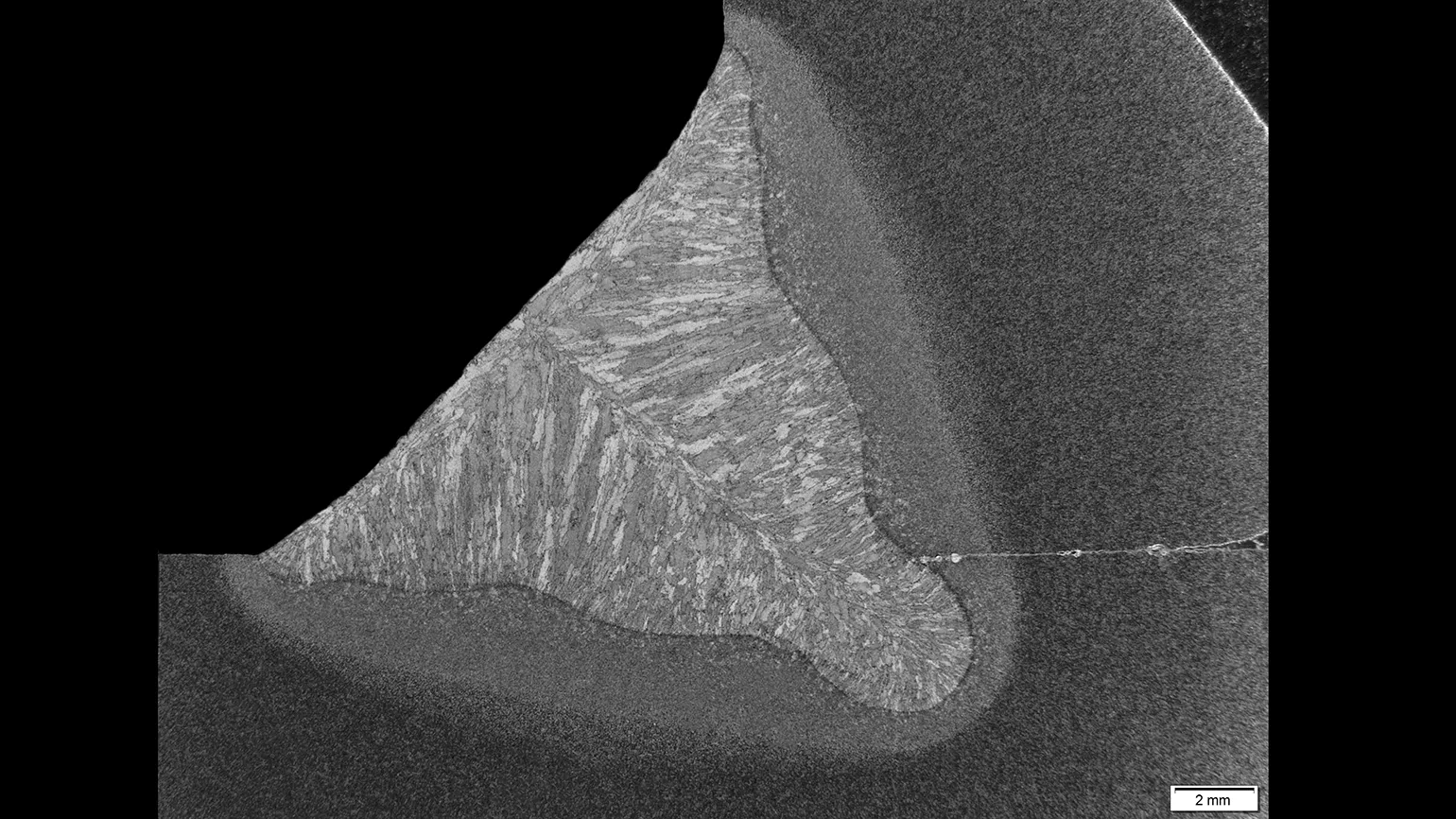

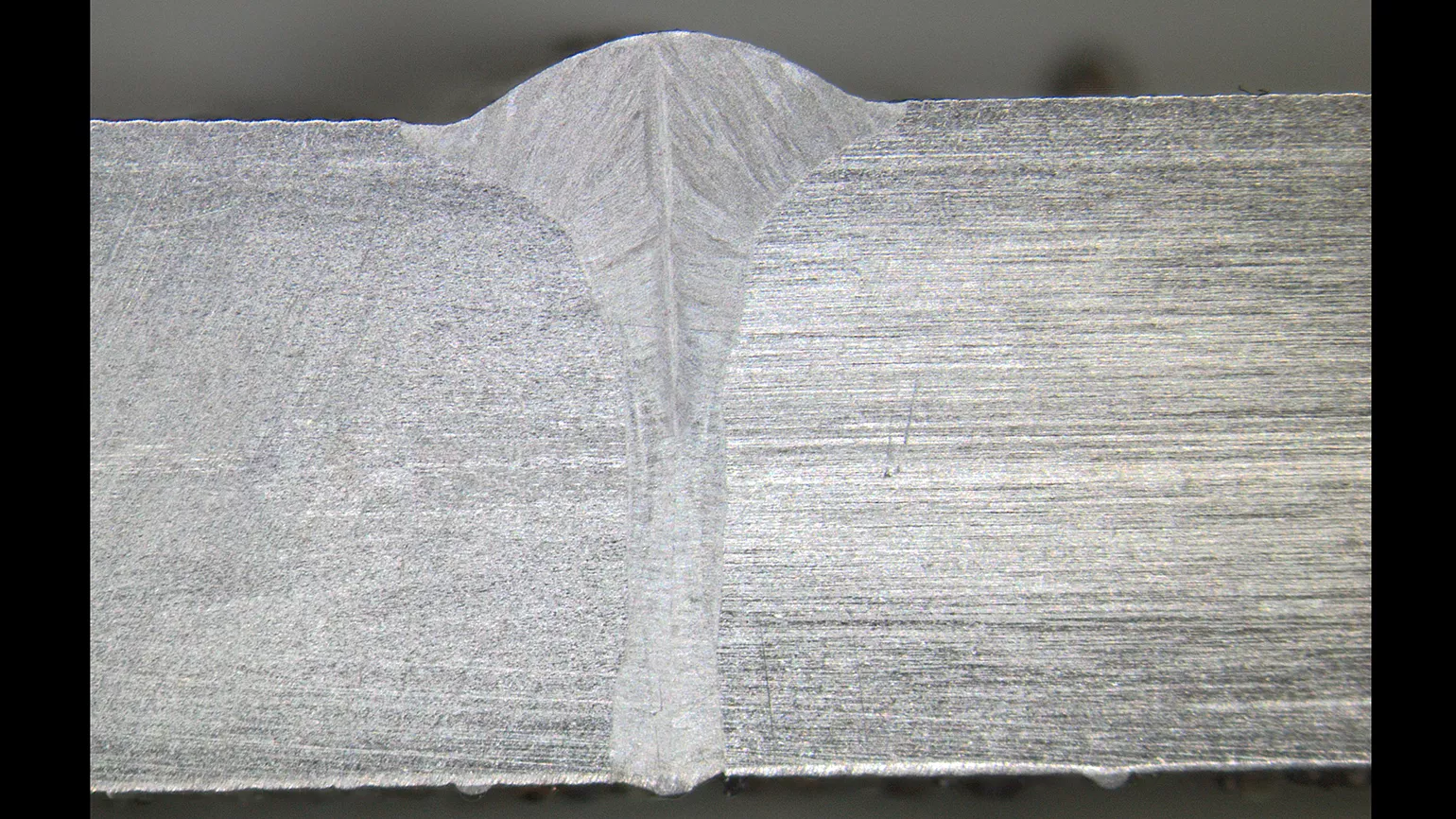

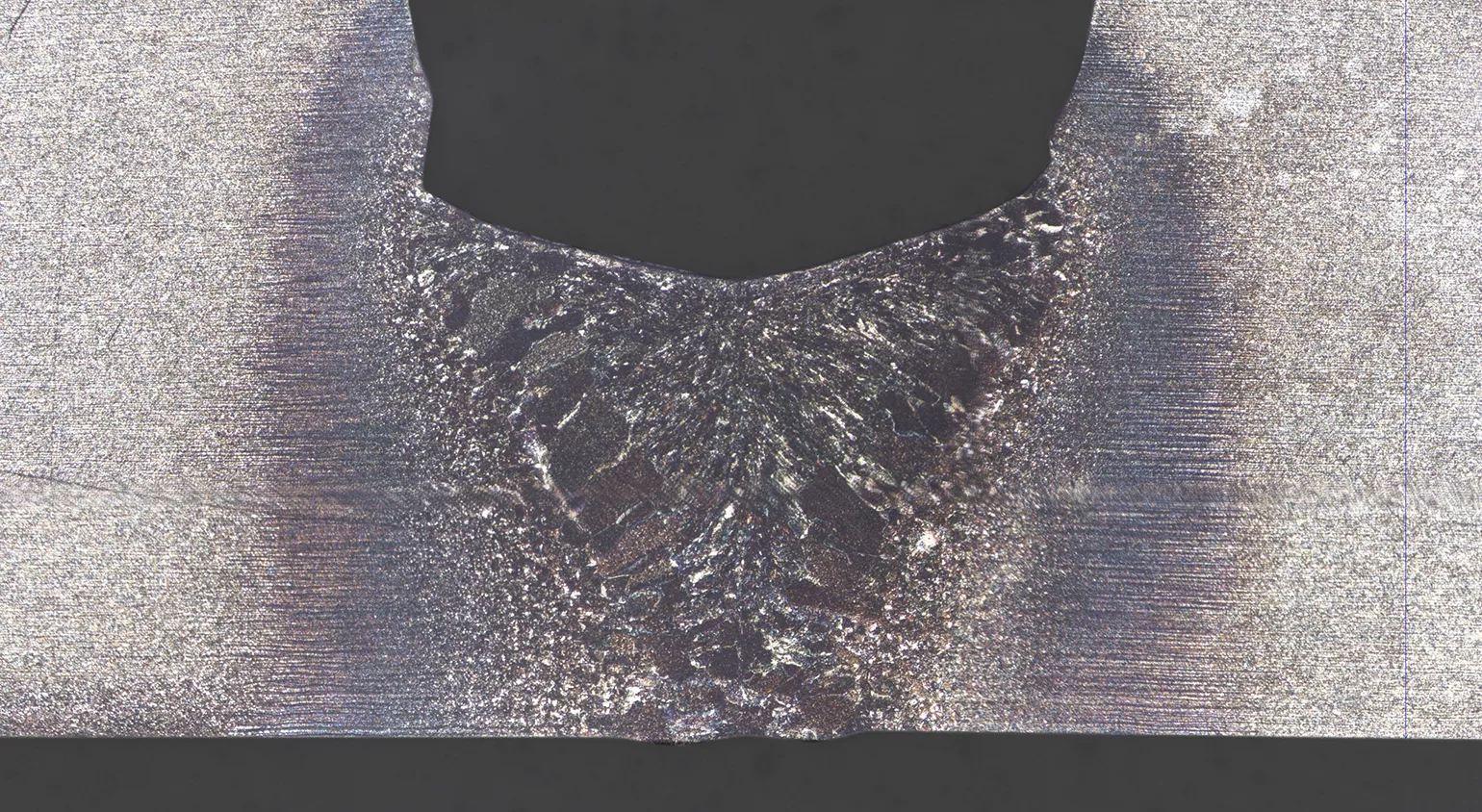

Butt weld

Challenges

- Deep penetration

- Single-pass welding

Solution

TPS/i TWIN Push

- Material thickness: 15 mm

- Welding speed: 60 cm/min

- Deposition rate: 20 kg/h

Challenges

- Stable ignition

- Robust welding torch

- Interval welding

Solution

TransSteel 3500

- Material thickness: 10 mm

- Welding speed: 25 cm/min

Telescopic handler

Fillet weld

Challenges

- High welding speed

- Low heat input

- High deposition rate

Solution

TPS TWIN CMT

- Material thickness: 8 mm

- Welding speed: 150 cm/min

- Deposition rate: 13 kg/h

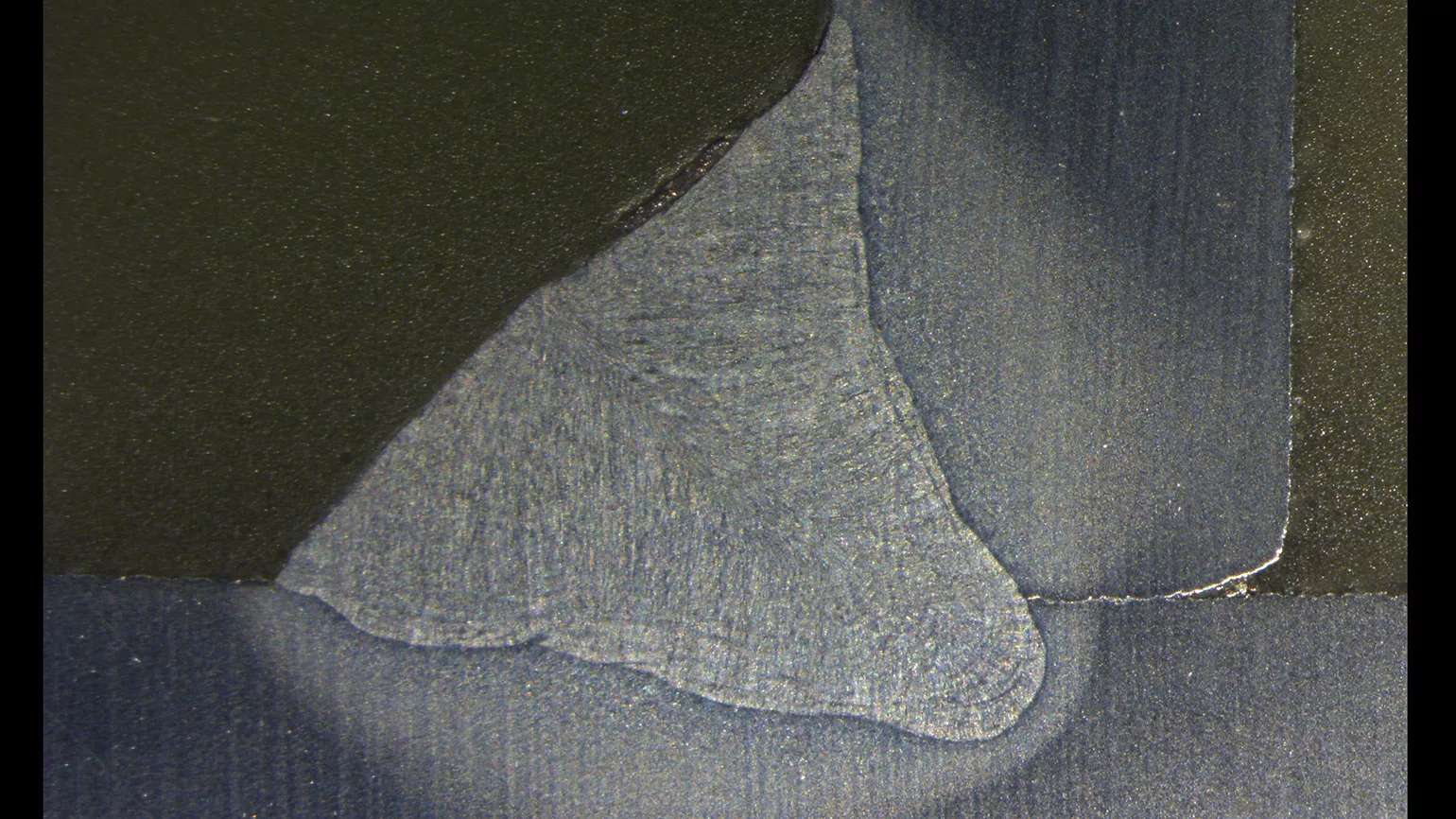

Butt weld

Challenges

- Horizontal position

- Single-layer welding

- No backing

Solution

LaserHybrid

- Material thickness: 6 mm

- Welding speed: 180 cm/min

- Deposition rate: 4 kg/h

Circumferential weld

Challenges

- Low-spatter

- High-quality weld seam appearance

- Excellent gap-bridging ability

- High welding speed

Solution

TPS/i TWIN Push

- Material thickness: 10 mm

- Welding speed: 100 cm/min

- Deposition rate: 22 kg/h

Fillet weld

Challenges

- Stable ignition

- Robust equipment

Solution

TransSteel 5000

- Material thickness: 8 mm

- Welding speed: 25 cm/min

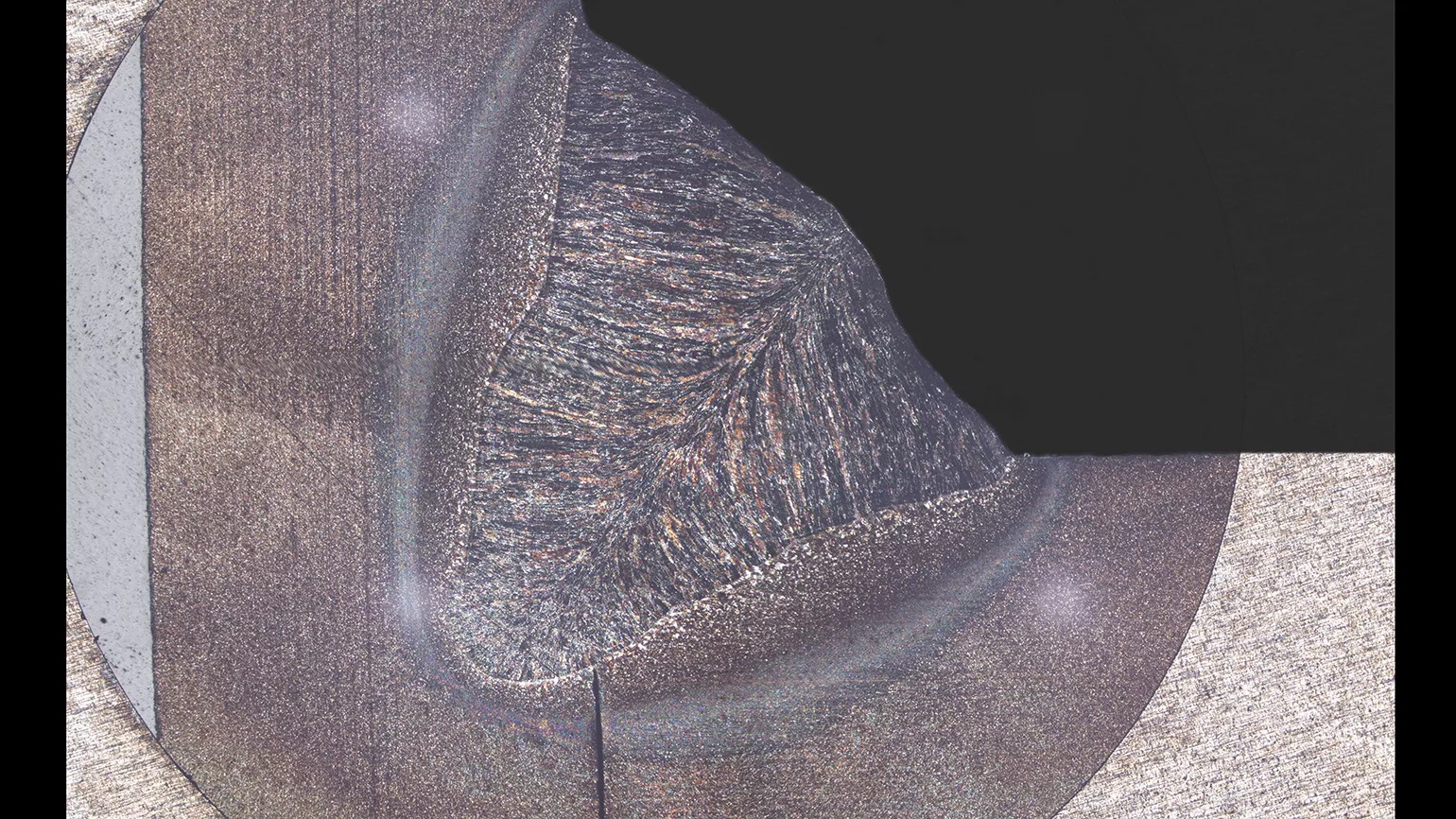

Root pass

Challenges

- Optimum weld seam quality

- No pores

- Start-stop overlap

- Root pass

Solution

ArcTig

- Material thickness: 10 mm / 5 mm root face

- Welding speed: 25 cm/min

Productivity and safety solutions

Let´s get connected!

System solutions for manual welding

Accessories

Production monitoring with WeldCube.

One piece of software - all power sources at a glance.

Process and cost optimization are of central importance for the automotive and supplier industry, and the documentation of production data is an important key to achieving this. With WeldCube from Fronius, you can continuously record and analyze the welding data of all power sources on all production lines.

The result: greater transparency, safety and verifiable weld quality for your series production.

How data analysis improves the world of welding!

Fronius has developed the WeldCube documentation and data analysis system. As a result, welding processes can be optimized and errors avoided.Global sales and service network

Fronius offers tailored services to customers around the world. We can advise you on our systems in advance and perform welding trials. Our service network makes us a reliable partner, including for aftersales support – we currently have 87 sales and service teams worldwide.

For our customers, this means:

- Proximity to market

- Quick response times

- Expert support from local contacts