MIG Welding Torches

for Robotic Applications

From difficult to access components to remote job sites:

Fronius welding torches are designed to cover a broad range of applications. Different torch necks of different lengths and angles make life easier. Welders can count on the flexibility they need with Fronius – guaranteed.

Benefits

Long wearing part lifetimes

Designed and manufactured for the longest service life and for optimal heat dissipation. High-quality materials guarantee a long lifetime.

Long service life

Top-quality components maximize the service life of the welding torch.

Flexible

We offer torch bodies of different lengths and angles, giving you the best flexibility for your application.The system at a glance

High compatibility with third-party devices

FSC - One connection for all media

The Fronius System Connector (FSC) serves as a central connection for all media. This ensures the hose pack to be connected easily and safely to the wire feeder in less than 10 seconds - without tools. For welding equipment from other manufacturers, 4 different central connection variants (suitable for Euro, Lincoln, Miller, Hobart) are offered to guarantee the highest possible compatibility. For this purpose standalone hose packs with corresponding connectors or adapters for existing hose packs are offered. You can get more detailed information from our sales consultants.

Optional:

Water cooling system

On water-cooled systems the cooling system has been brought forward and outward as far as possible. The shape of the contact tip means that less radiant heat is now absorbed.

This alone brings a temperature reduction of up to 70 °C / 158 °F for the wearing parts.

Welding fume extraction

Exento extraction kit for robot welding torch

Precise extraction at exactly the point where the welding fumes are generated.

All welding processes generate a mix of fumes and gases that will adversely affect the health of the welder unless adequate protective measure are implemented. The Exento extraction kit for robot welding torches removes the welding fumes at exactly the point they are generated, and before they have a chance to spread.

Advantages:

- Direct extraction of welding fumes at their point of origin

- Very good fume capture by positioning of the extraction nozzle directly on the gas nozzle

- Optimum protective gas shield even with normal amounts of gas: special geometry of extraction nozzle

Consumables

Inner Liners

- The right inner liner for every material

- Simple, fast & tool-free change

Contact tip variants

- The right contact tip for all applications and wire diameters

Supporting peripheral devices

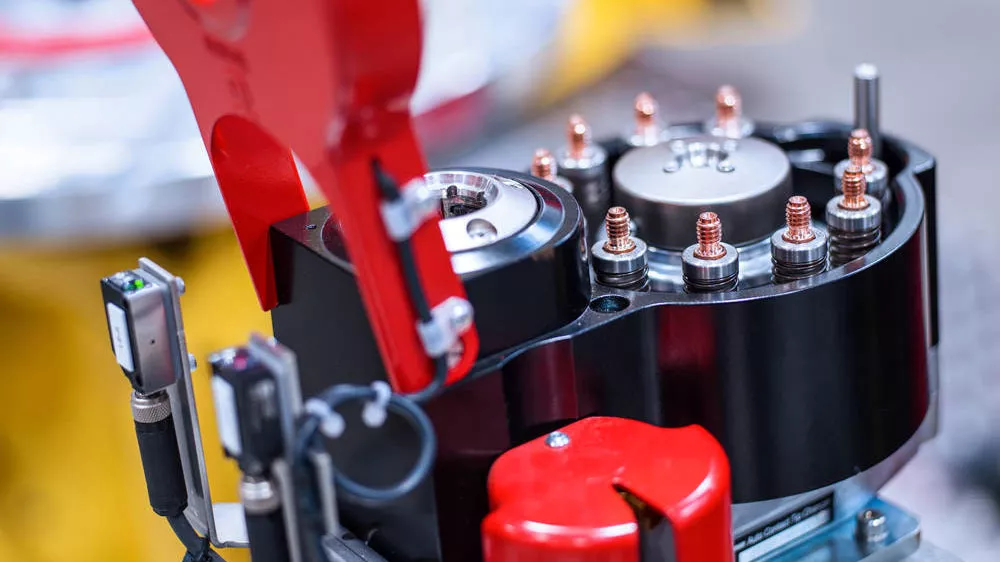

Robacta CTC

Automatic contact tip changer

Designed to automatically change the contact tip while production continues

- Replace the contact tip in just 50 seconds

- Replace 10 contact tips without manual intervention

- Changeover cycle adapted to the contact tip wear

- Consistent weld seam quality

- Ensures correct torque

Quick ROI

The Robacta CTC extends robot service life, lowers production costs, and avoids the potential for human error in manual operation. An investment that pays for itself!

Use our payback calculator to check your savings and the payback period.

Contact Tip Changer available for following torch bodies

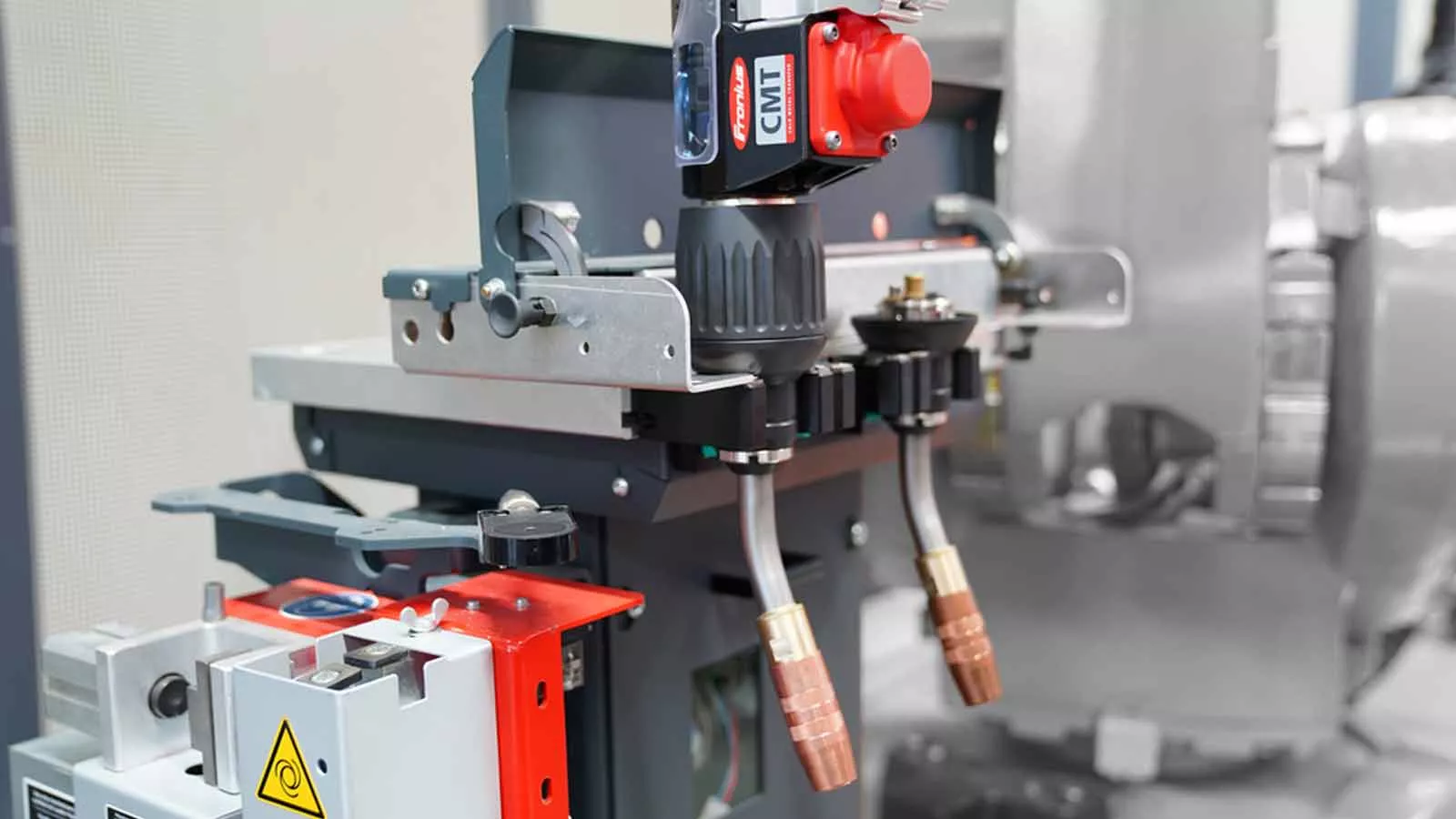

Robacta TX/i

Automatic torch body changeover in just 30 seconds

The complete torch body is changed automatically without the need for human intervention while production continues. This ensures that all wearing parts that impact on the TCP and weld seam quality are replaced

Robacta TC 2000

Robacta TC touchlessly cleans the torch in automated steel applications. The surfaces of the wearing parts remain undamaged, and the lifespan of the gas nozzle is prolonged. The constantly defined cleaning power has a magnetic flux density of up to 4.7 Tesla, giving a standard plain washer a mass equivalent to around 3 kg (6.61 lb).

Touchless magnetic cleaning:

- In contrast to cleaning with a cutter, there is no damage to the surfaces of wearing parts

- Does not affect TCP (Tool Centre Point)

Improved cost-effectiveness

- Greater availability of robot system as less maintenance required

- Service life of gas nozzle increased by a factor of ten compared with mechanical cleaning methods

- No maintenance-intensive cleaning components and wearing parts required

Universal and compact

- Can be integrated in all existing robot cells and available for practically every torch geometry

- Compact design for space-saving use

Robacta Reamer Easy V

Robacta Reamer V series are used to automatically clean MIG/ MAG welding torches. The Robacta Reamer V series cleaning devices allow you to clean the inside and front of the gas nozzle on a wide range of welding torch shapes. The result is a significant increase in the service life of wearing parts.

- Steel & Stainless steel applications

- Basic mechanical solution with Harting Han6P Connection for automated control (cable not included)

- Includes wire cutter

- Motor height must be adjusted based on application